A multi -functional efficiency increase agent and its preparation method for an acidified fracture

A multi-functional technology for acid fracturing, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor comprehensive performance of liquids, achieve low cost, convenient preparation, and prevent clay expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

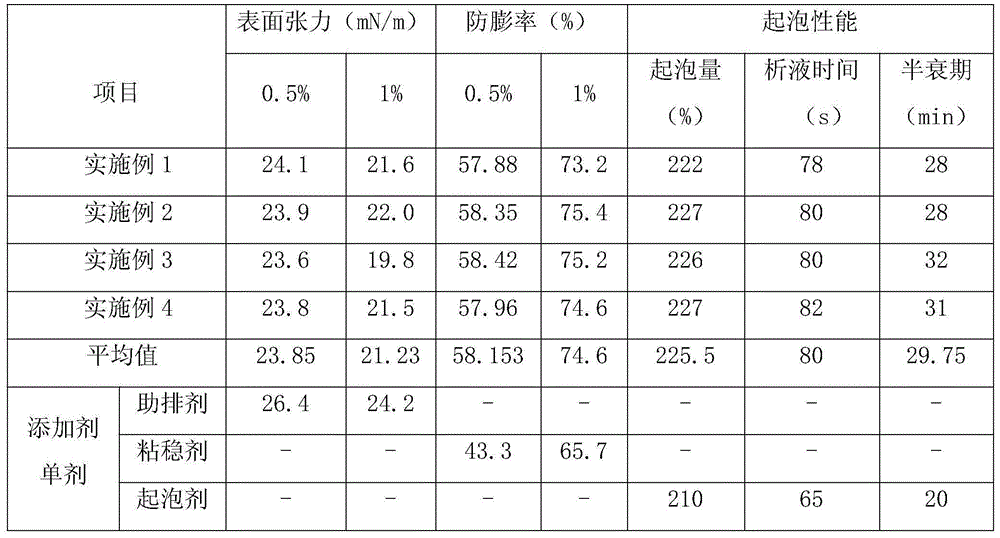

Examples

Embodiment 1

[0017] Embodiment 1: A multifunctional synergist for acidification fracturing, which is composed of the following raw materials in parts by weight: functional polymer compound: 30, fluorocarbon surfactant: 2, alkyl betaine: 6, iso Propanol: 3-7, water: 28.

[0018] The preparation method of the above-mentioned multifunctional synergist for acidizing fracturing, it comprises the following steps:

[0019] S1. Preparation of functional polymer compounds:

[0020] S11. Formation of secondary amine intermediate: Dilute ethyleneimine with water, lower the solution temperature to 5°C, add 0.08% solution weight of dibenzoyl peroxide, then add diethylamine dropwise, and keep the solution during the dropwise addition The temperature is 10°C, and after the dropwise addition, the solution is heated to 38°C for 4.8 hours to generate a secondary amine intermediate; wherein, the weight ratio of ethyleneimine, water, and diethylamine is 1:2.6:1, and the secondary Amines are synthesized from...

Embodiment 2

[0025] Embodiment 2: A multifunctional synergist for acidification fracturing, which is composed of the following raw materials in parts by weight: functional polymer compound: 50, silicon surfactant: 5, foaming agent: 10, solvent: 7 , water: 59.

[0026] The foaming agent is an alkyl glycoside surfactant and an alkyl diphenyl ether disulfonate, and the weight ratio is 3:1; the solvent is ethylene glycol and ethanol, and the weight ratio is 1:1.8.

[0027] The preparation method of the above-mentioned multifunctional synergist for acidizing fracturing, it comprises the following steps:

[0028] S1. Preparation of functional polymer compounds:

[0029] S11. Generation of secondary amine intermediate: Dilute ethyleneimine with water, add 0.12% solution weight catalyst after the solution temperature drops to 10°C, then add dimethylamine dropwise, keep the solution temperature at 5°C during the dropping process, After the dropwise addition, the solution was heated to 42°C for 5....

Embodiment 3

[0034] Embodiment 3: A multifunctional synergist for acidification fracturing, which is composed of the following raw materials in parts by weight: functional polymer compound: 38, special surfactant: 3, foaming agent: 7, solvent: 5 , water: 35.

[0035] The special surfactant is a fluorocarbon surfactant and a silicon surfactant, and the weight ratio is 5:2; the foaming agent is an alkyl betaine, an alkyl glycoside surfactant and an alkyl diphenyl ether diphenyl ether. Sulfonate, and the weight ratio is 1:3:1.5; the solvent is isopropanol, ethylene glycol and ethanol, and the weight ratio is 4:1.8:3.

[0036] The preparation method of the above-mentioned multifunctional synergist for acidizing fracturing, it comprises the following steps:

[0037] S1. Preparation of functional polymer compounds:

[0038] S11. Generation of secondary amine intermediate: Dilute ethyleneimine with water, add 0.1% solution weight catalyst after the solution temperature drops to 7°C, then add di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com