One-way device assembly

A one-way device and assembly technology, which is applied in the direction of one-way clutches, clutches, mechanical equipment, etc., can solve the problems of easy movement of the contact surface, affect the quality of use, and short service life, so as to achieve strong sealing and reduce the use of The effect of improving the service life and quality of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

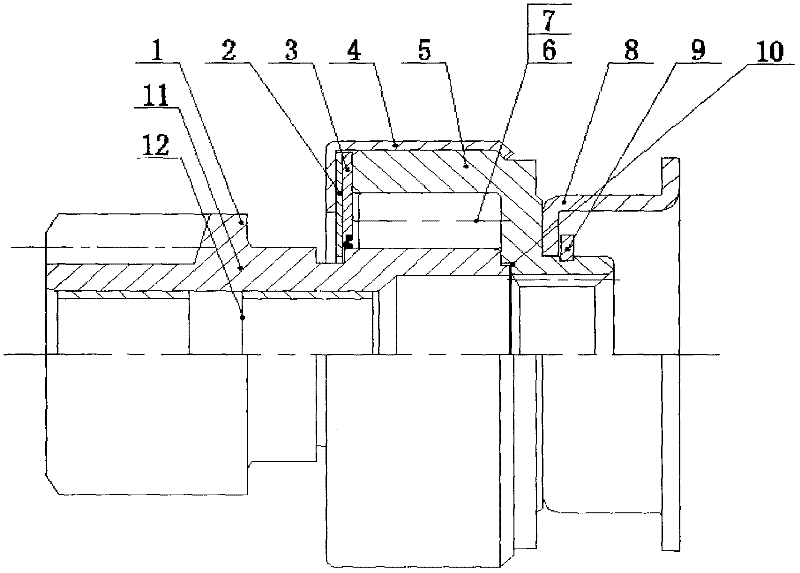

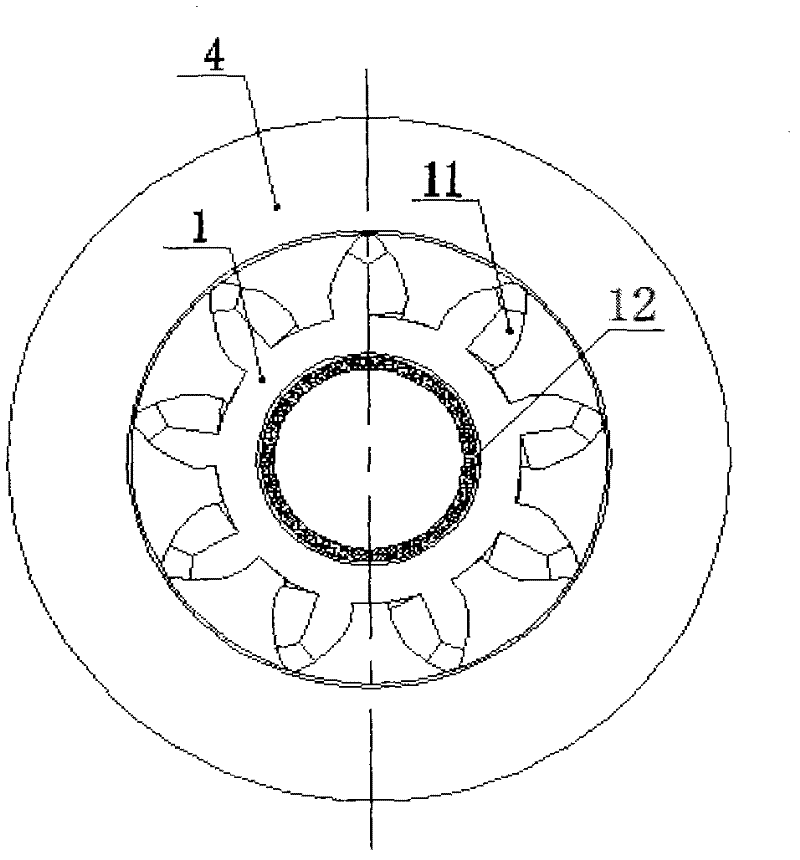

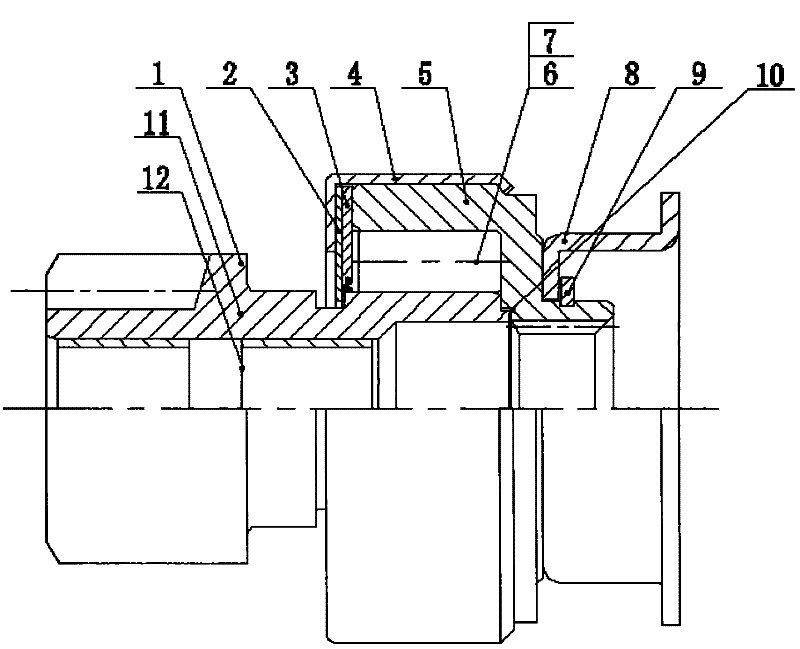

[0012] Such as figure 1 , figure 2 As shown, a checker assembly includes: a gear part 1, a collar 2, an oil seal pressure ring 3, a star wheel 5, a roller 6, a flat spring 7, and a case 4. The gear part 1 includes a gear 11 and a bushing 12, a bushing 12 is installed on the inner wall of the gear 11, and the bushing 12 is made of tin bronze, a high-strength wear-resistant material. The evenly distributed diamond-shaped pits are installed in the diamond-shaped pits with graphite blocks of the same shape, and the graphite blocks are used to improve the friction resistance; the material of the oil seal pressure ring 3 is rubber material with strong wear resistance and sealing; the roller 6 and the flat spring 7 are put into the curved surface cavity of the star wheel 5 and injected with an appropriate amount of lubricating grease. The oil seal pressure ring 3 is spread on the star wheel 5, and the gear part 1 slides into the star wheel through the roller 6. In the cavity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com