Light diffusion light-emitting diode (LED) lamp

A technology of LED lamps and beams, applied in optics, light guides, light sources, etc., can solve the problems of unstable luminous flux and color temperature, poor effect, and excessive materials, so as to improve the maintenance rate of luminous flux, improve luminous flux, and solve glare. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

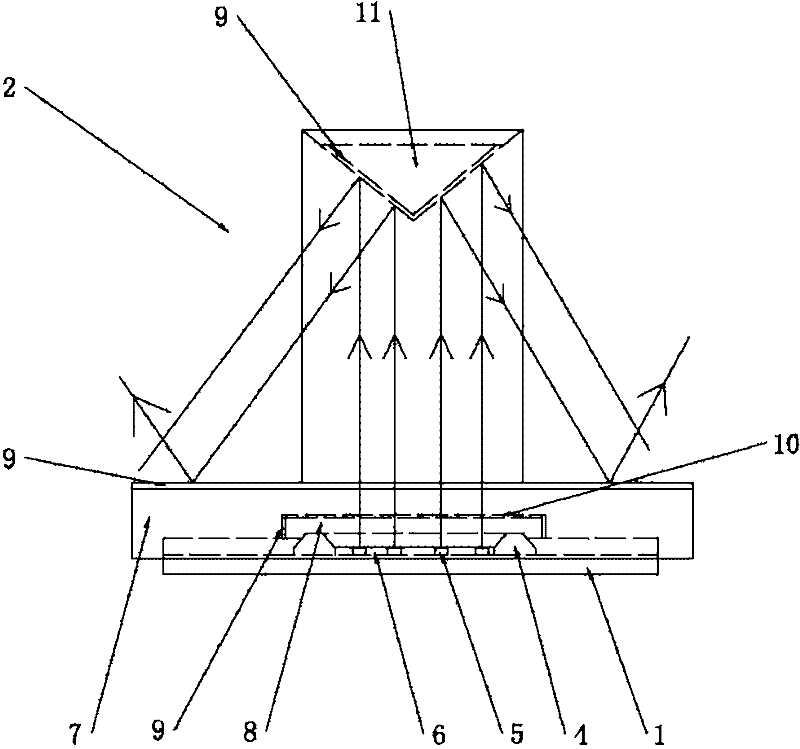

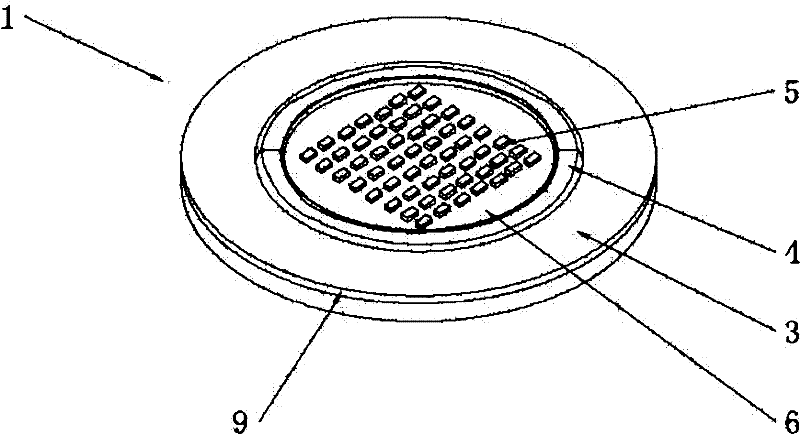

[0025] Implementation mode one: if Figures 1 to 3 As shown, the light-expanding LED lamp of the present invention is mainly composed of an LED blue light chip 1 and a transparent light guide column 2, wherein the substrate 3 of the above-mentioned LED blue light chip 1 is provided with a surrounding wall 4 made of a heat-conducting plastic surface silver-plated, its The chip 5 is arranged in the wall 4, and the upper surface of the substrate 3 in the wall 4 is covered with a transparent heat-conducting layer 6. The lower part of the above-mentioned transparent light guide column 2 is provided with a cover plate 7, and the bottom surface of the cover plate 7 is provided with a matching LED blue light chip 1. Stepped groove, the side wall of the second stepped groove 8 and the upper surface of the cover plate 7 are provided with a reflective layer 9, the top surface is provided with a fluorescent layer 10, the top of the above-mentioned transparent light guide column 2 is provid...

Embodiment approach 2

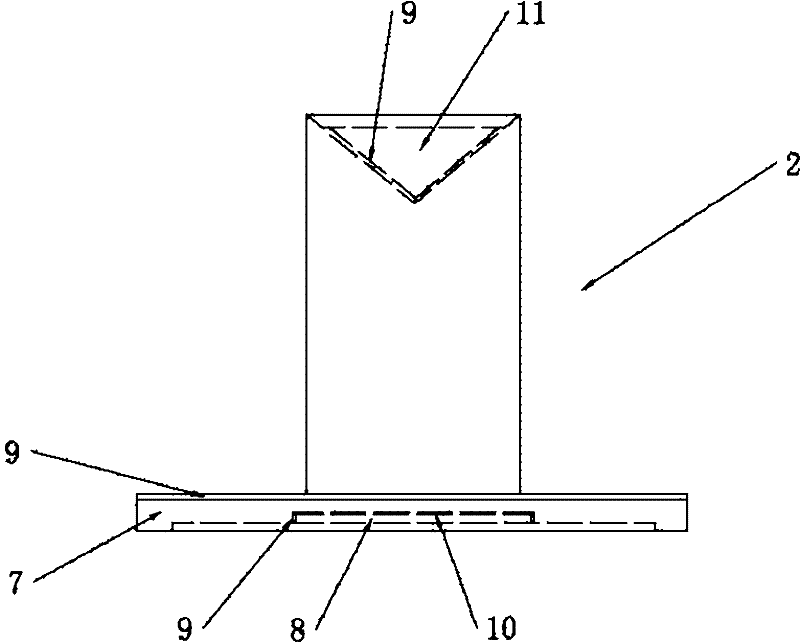

[0033] Implementation mode two: if Figures 3 to 5 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the above-mentioned reflective structure is a reflector 12 arranged on the top of the transparent light guide column 2, and the bottom surface of the reflector 12 is provided with a reflective layer 9, which can be arranged on The light excited by the chip 5 in the middle part of the LED blue light chip 1 is reflected. Light reflection to achieve the effect of light expansion.

[0034] Wherein, in this embodiment, the transparent heat conduction layer 6 disposed in the upper surface wall 4 of the substrate 3 is made into a convex lens, and the transparent light guide column 2 is made of polycarbonate, and its cover plate 7 is integrated with the transparent light guide column 2 .

[0035] The enclosure wall 4 of this embodiment is made of brushed nickel plated on the copper surface.

Embodiment approach 3

[0036] Embodiment 3: This embodiment is basically the same as Embodiment 1, the difference is that the substrate 3 of the LED blue light chip 1 that matches the cover plate 7 is made of aluminum, and the wall 4 arranged on the substrate 3 is made of copper alloy The surface is made of brushed nickel, which makes it have a good reflective effect.

[0037] In this embodiment, the reflective structure arranged on the top of the transparent light guide column 2 is a cavity 11 with an irregular shape, and the cavity 11 is provided with a reflective layer 9 made of a copper alloy surface coated with brushed nickel.

[0038] The above-mentioned transparent heat-conducting layer 6 arranged in the surrounding wall 4 is made into a concave mirror to achieve the function of primary light distribution.

[0039] sketches.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com