Refrigerating system with ejector and refrigerating method thereof

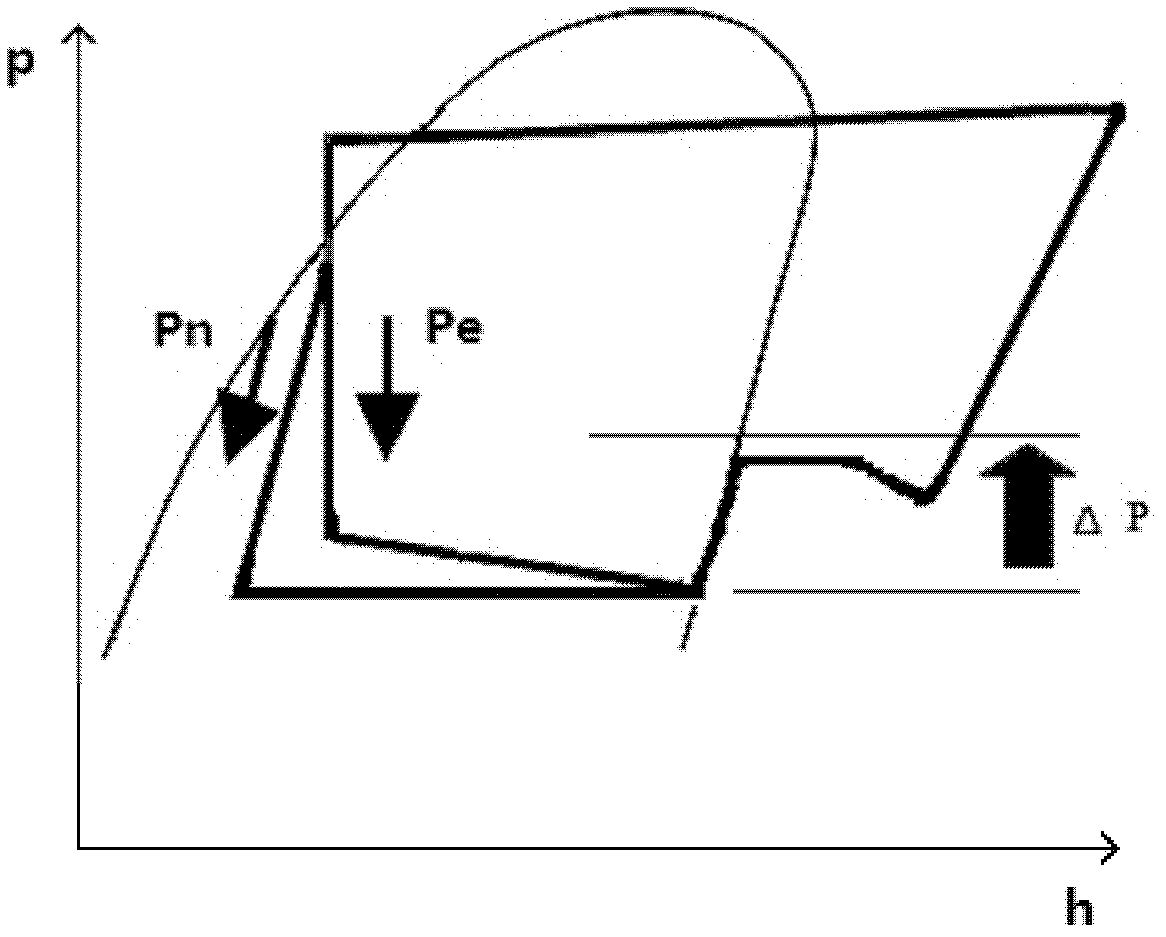

A refrigeration system and ejector technology, which is applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve problems such as troublesome cooling capacity of the refrigeration system, affecting the stability of the refrigeration system, and reducing the efficiency of the ejector, so as to increase the pressure, Avoid efficiency decline and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

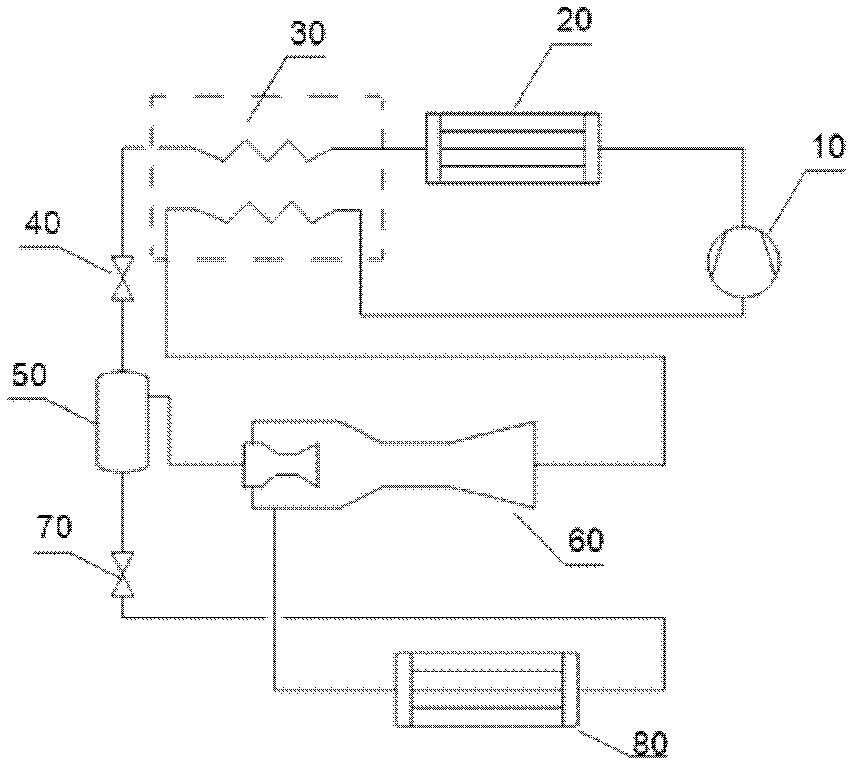

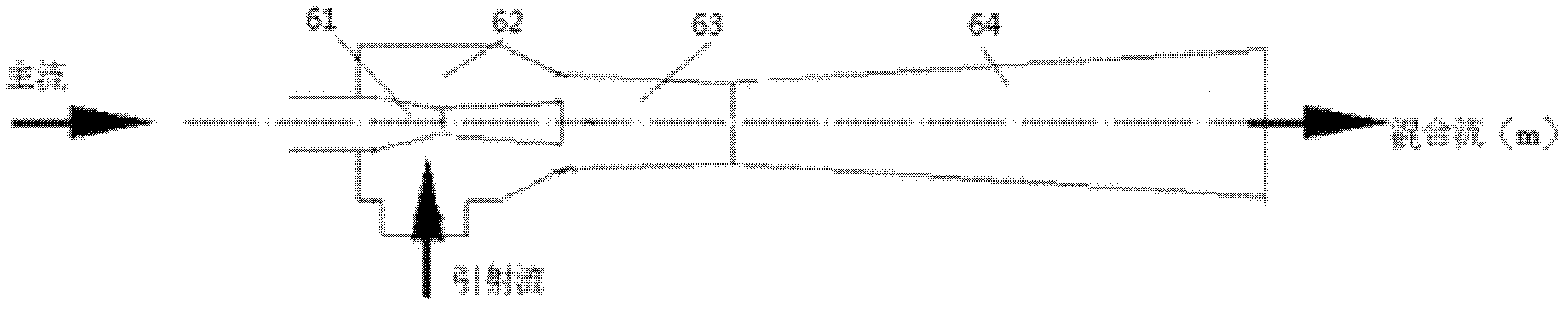

[0017] Such as figure 1 As shown, the refrigerating system with ejector of the present embodiment is composed of compressor 10, condenser 20, intermediate heat exchanger 30, expansion valve 40, gas-liquid separator 50, ejector 60, expansion valve 70 and evaporator 80 compositions. The connection relationship between the components: the outlet of the compressor 10 is connected to the inlet of the condenser 20, and then the outlet of the condenser 20 is connected to the inlet of the first side of the intermediate heat exchanger 30, and then the outlet of the first side of the intermediate heat exchanger 30 The outlet is connected with the inlet of the expansion valve 40, and then the outlet of the expansion valve 40 is connected with the inlet of the gas-liquid separator 50, and then the gas outlet of the gas-liquid separator 50 is connected with the main flow inlet of the injector 60, and the liquid of the gas-liquid separator 50 The outlet is connected to the inlet of the exp...

Embodiment 2

[0023] Such as Figure 4As shown, this embodiment includes: a refrigeration system with an ejector, which is composed of a compressor 10 , a condenser 20 , an expansion valve 40 , a gas-liquid separator 50 , an ejector 60 , an expansion valve 70 , and an evaporator 80 . The connection relationship of each component: the compressor 10 is connected to the condenser 20, then the condenser 20 is connected to the expansion valve 40, then the expansion valve 40 is connected to the gas-liquid separator 50, and then the gas outlet of the gas-liquid separator 50 is connected to the ejector 60 The main flow inlet is connected, and the liquid outlet of the gas-liquid separator 50 is connected with the expansion valve 70, and then the expansion valve 70 is connected with the evaporator 80, and then the evaporator 80 is connected with the ejector 60 gas injection inlet, and then the ejector 60 is connected with the compressor 10 connections to form a complete loop.

[0024] After being co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com