High-speed unordered capsule defect detecting system

A defect detection and capsule technology, which is applied in the direction of optical defect/defect detection, can solve problems such as increased cost, small detection throughput, and confidentiality of technical details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

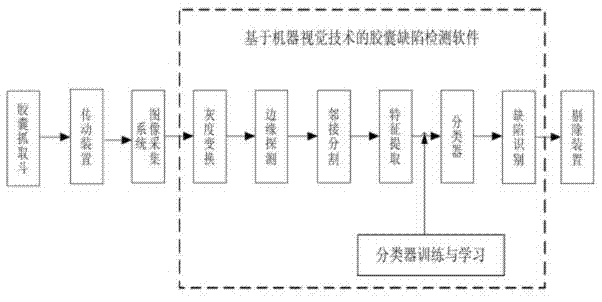

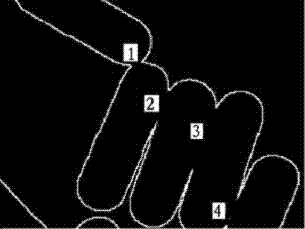

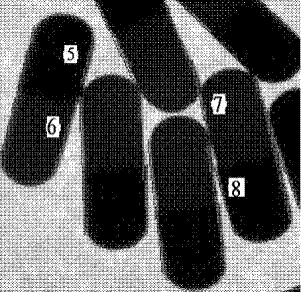

[0029] combine figure 1 As shown in the flow chart of the invention, the process of adopting the high-speed disordered capsule defect detection system of the present invention is as follows: first, the capsule is placed on the assembly line through the capsule grabbing bucket; then the capsule is transmitted to the image capture window through the transmission device to collect the original image; Then, the collected original image is used for defect identification; finally, the signal of whether there is a defect is sent to the rejecting device, and the defective capsule is removed from the conveyor belt.

[0030] 1. Transmission and vibration device:

[0031] The transmission device is a necessary link in the detection of capsules, and the detection objects are continuously and batch-transmitted to the detection window through the transmission device. At present, the main transmission device can be divided into two ways: orderly arrangement (capsules are transported by neat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com