Circulated cooling water operation optimization control system for industrial enterprise

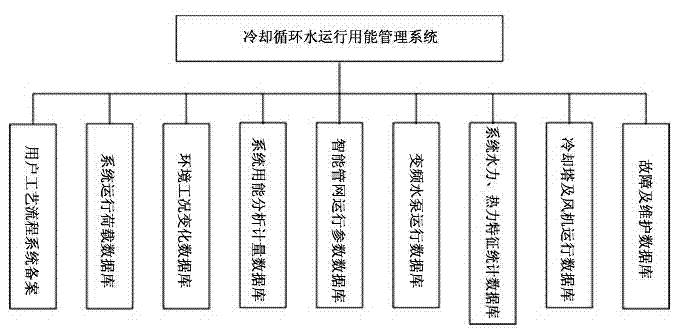

A technology for cooling circulating water and optimizing operation, which is applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., and can solve problems such as incompleteness, impossibility, and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

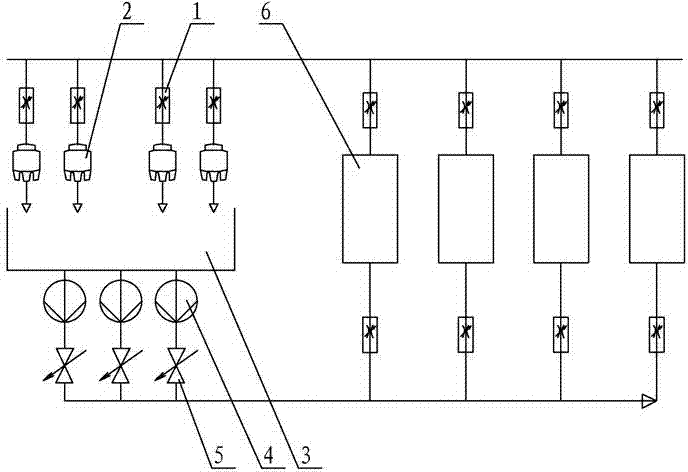

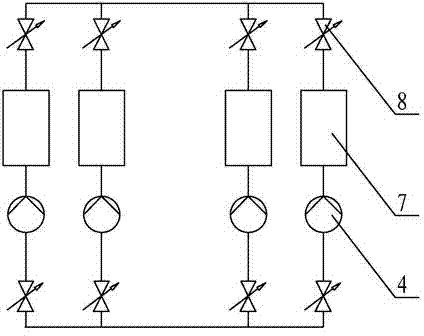

[0069] In the actual operation process, the water supply and return pipes of the terminal water link are respectively installed as follows: figure 1 The intelligent balance valve shown in the figure, wherein the intelligent balance valve of the return water pipeline is an intelligent balance valve with return water temperature feedback and communication functions. During operation, for different terminal water links, the required return water temperature limit must be different according to the characteristics of the user itself. The intelligent balance valve with temperature feedback and communication functions can directly control the amount of cooling water supplied to the corresponding link directly according to the change rate of the return water temperature of each end user and the value of the return water temperature. The goal is to control the return water temperature of the corresponding link. Within the specified temperature limit range, and at the same time, the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com