Workplace benzene occupational exposure and carcinogenic risk analysis method

A technology for workplace and risk analysis, applied in the field of occupational exposure and carcinogenic risk analysis, which can solve problems such as lack of health risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

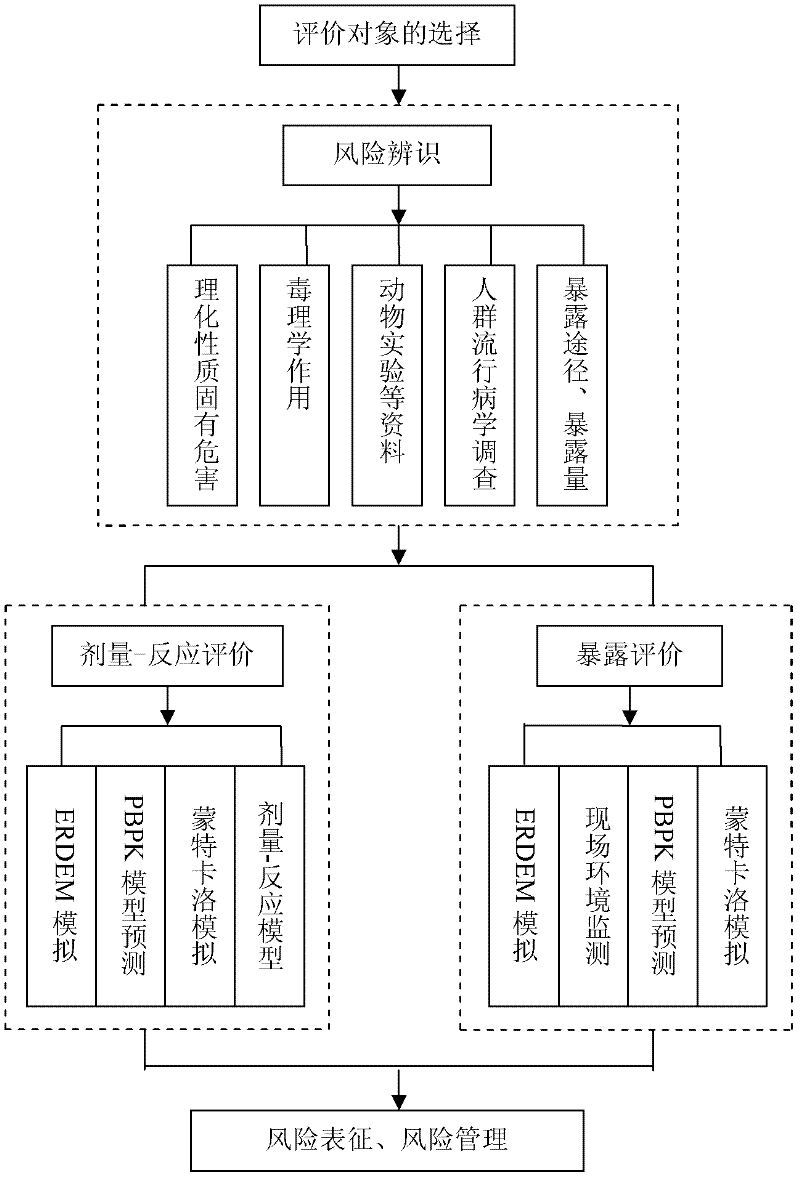

[0052] For the technical content and method implementation steps of occupational exposure to benzene and carcinogenic risk analysis in the workplace, see image 3 .

[0053] Case Study of Occupational Exposure to Benzene

[0054] 1. Risk identification

[0055] (1) Occupational hazard factors and exposure routes

[0056] A large-scale petrochemical company newly built a 500,000-ton / year styrene production plant, using the traditional process of catalytic dehydrogenation of ethylbenzene to produce styrene. The main raw materials for production are ethylene and benzene, and there are a large amount of benzene and ethylene in each process unit. , ethylbenzene and other toxic and harmful substances.

[0057] Styrene production is carried out in an open-air closed environment, with mature and advanced production technology and a high degree of automation, which has caused a lot of misunderstanding in people's understanding. The dose is very small, the degree of exposure will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com