Conducting liquid contact-type friction-free rotary potentiometer

A conductive liquid, contact technology, applied in the direction of liquid resistors, etc., can solve the problems of non-sealing, mechanical friction of metal moving contacts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

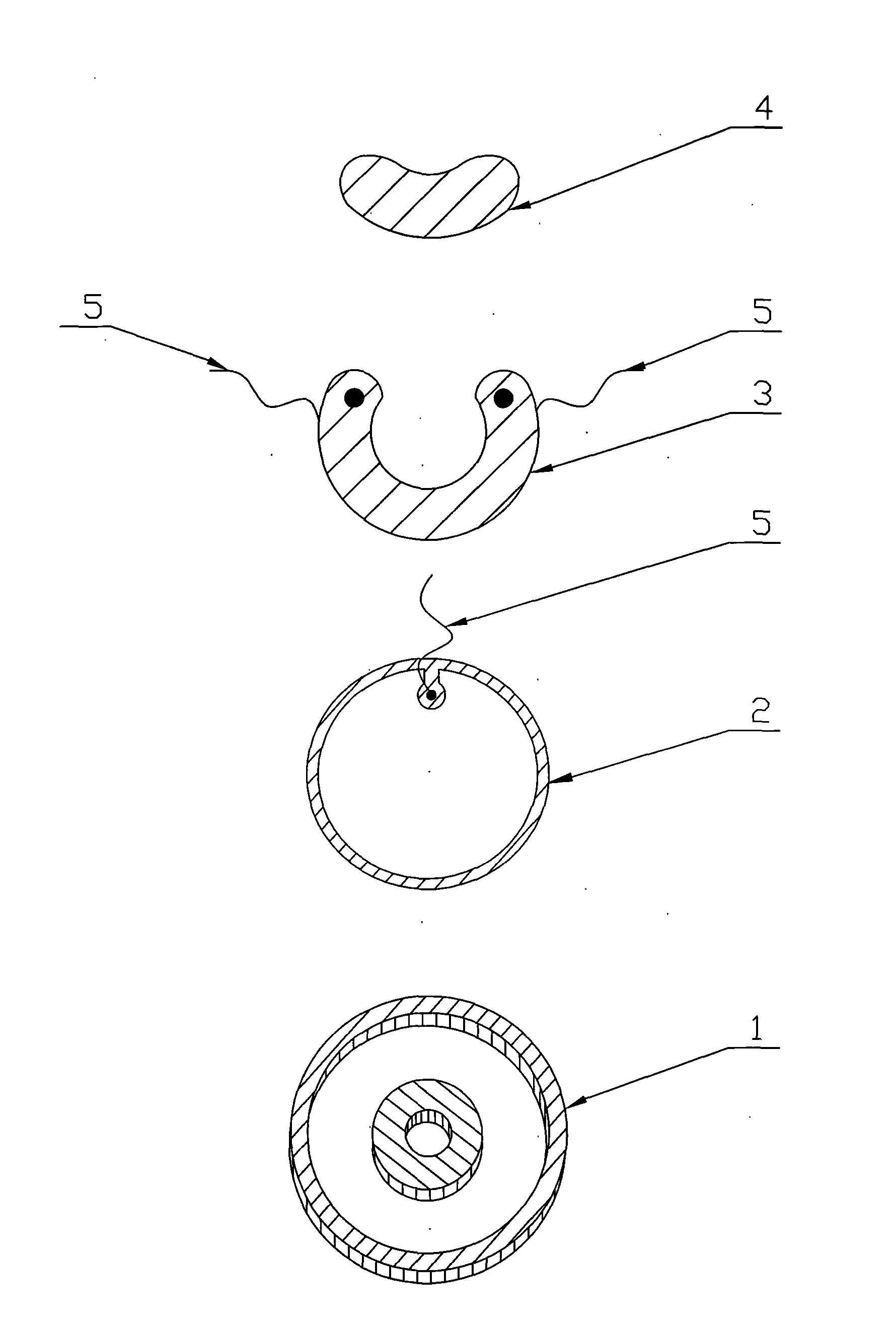

[0007] The conductive liquid contact type frictionless rotary potentiometer is processed like this. The material is made of 1mm plexiglass plate, and two rings with an outer radius of R1 and an inner radius of R4 are processed by a cutting lathe, marking A and B. The material is made of 3mm plexiglass plate, and a circle with an outer radius of R1 and an inner radius of R2 is processed by a cutting lathe, and the symbol C is used. A circle whose outer radius is R3 and whose inner radius is R4 marks D piece. The relationship between radius and length: where R1》R2》R3》R4. Assembly process: take piece A and lay it flat, take pieces C and D, and after one side is coated with glue, stick the concentric circles on the piece A. After sticking firmly, an annular groove is formed between R2 and R3 of C and D on A and D. The thickness (3mm) of the C piece and the D piece shall ensure that the depth of the annular groove is sufficient to install the circular arc-shaped exposed fixed re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com