Sine wave disk type permanent magnet generator with novel magnetic pole structure

A technology for permanent magnet generators and disk generators, which is applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc. It can solve the problems of low utilization rate of iron core and difficult cooling of motors, so as to improve efficiency and simplify Installation and fixing methods, the effect of reducing manufacturing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

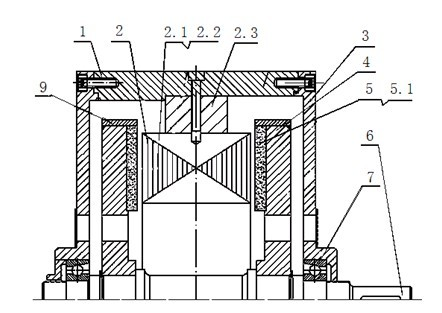

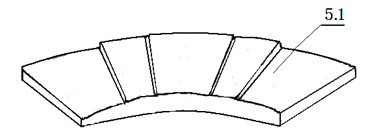

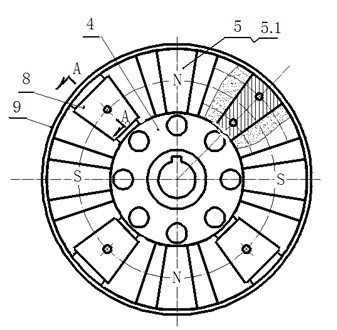

[0029] Such as figure 1 , 2 , 3, and 4, a sine wave disc permanent magnet generator with a new magnetic pole structure, including a base 1, a stator disc 2, a rotor disc 4 installed on both sides of the stator disc 2, fixed on the rotor disc 4 The magnetic pole 5 on the top, and the end cover 3, the rotating shaft 6 and the bearing 7; the magnetic pole 5 is composed of an even number of fan-shaped pole pieces 5.1 fixed on the rotor disk 4; as image 3 As shown, there are four fan-shaped pole pieces 5.1 in this embodiment; the fan-shaped pole pieces 5.1 are evenly distributed around the center of the rotor disk 4 along the circumference and fixed on the side of the rotor disk 4 facing the stator disk 2; figure 2 As shown, the side profile of each fan-shaped pole piece 5.1 facing the side of the stator plate 2 is stepped, and the middle of the ladder shape is a high step, and it descends symmetrically to both sides to a low step; two adjacent fan-shaped pole pieces 5.1 The di...

Embodiment 2

[0031] The difference from the first embodiment above is that the sector-shaped pole piece 5.1 has three steps, and the arc lengths of the symmetrical low steps on both sides of the middle high step are half of the arc length of the middle high step. When the arc lengths of the symmetrical low steps on both sides of the middle high step are equal to the arc length of the middle high step, it is a new embodiment.

Embodiment 3

[0033] Different from the above-mentioned embodiment 1, the sector-shaped pole piece 5.1 has 9 steps, wherein the arc lengths of the symmetrical low steps located at both ends are respectively equal to the arc lengths of the middle high steps, and the arc lengths of each of the remaining symmetrical low steps are respectively Half the arc length of the middle high step. When the arc length of each symmetrical low step is equal to the arc length of the middle high step, it is a new embodiment.

[0034] Figure 5 with Figure 7 Respectively, the no-load back EMF waveform calculated by simulation and the measured no-load back EMF waveform, Image 6 with Figure 8 The simulated load current waveform and the measured load current waveform are respectively. The comparison between the simulated calculation and the experimental test waveform shows that the amplitude and waveform of the simulated no-load back EMF waveform and the load current waveform are very close to the experimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com