Stem guide apparatus for use with fluid valve actuators

A technology for guiding devices and actuators, applied in fluid pressure actuating devices, valve devices, valve operation/release devices, etc., which can solve problems such as damage, friction, curling, and reduction of effective diaphragm area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

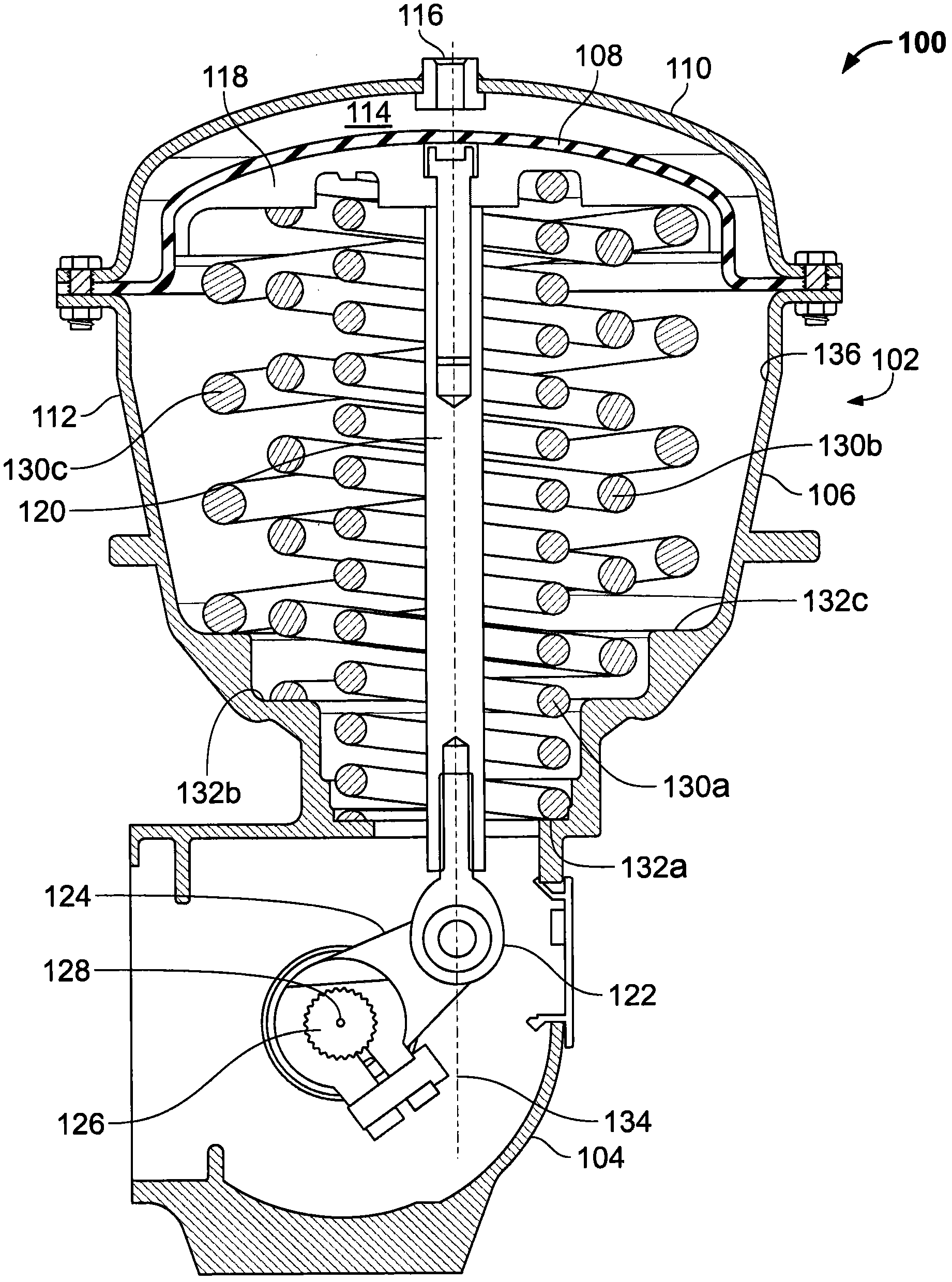

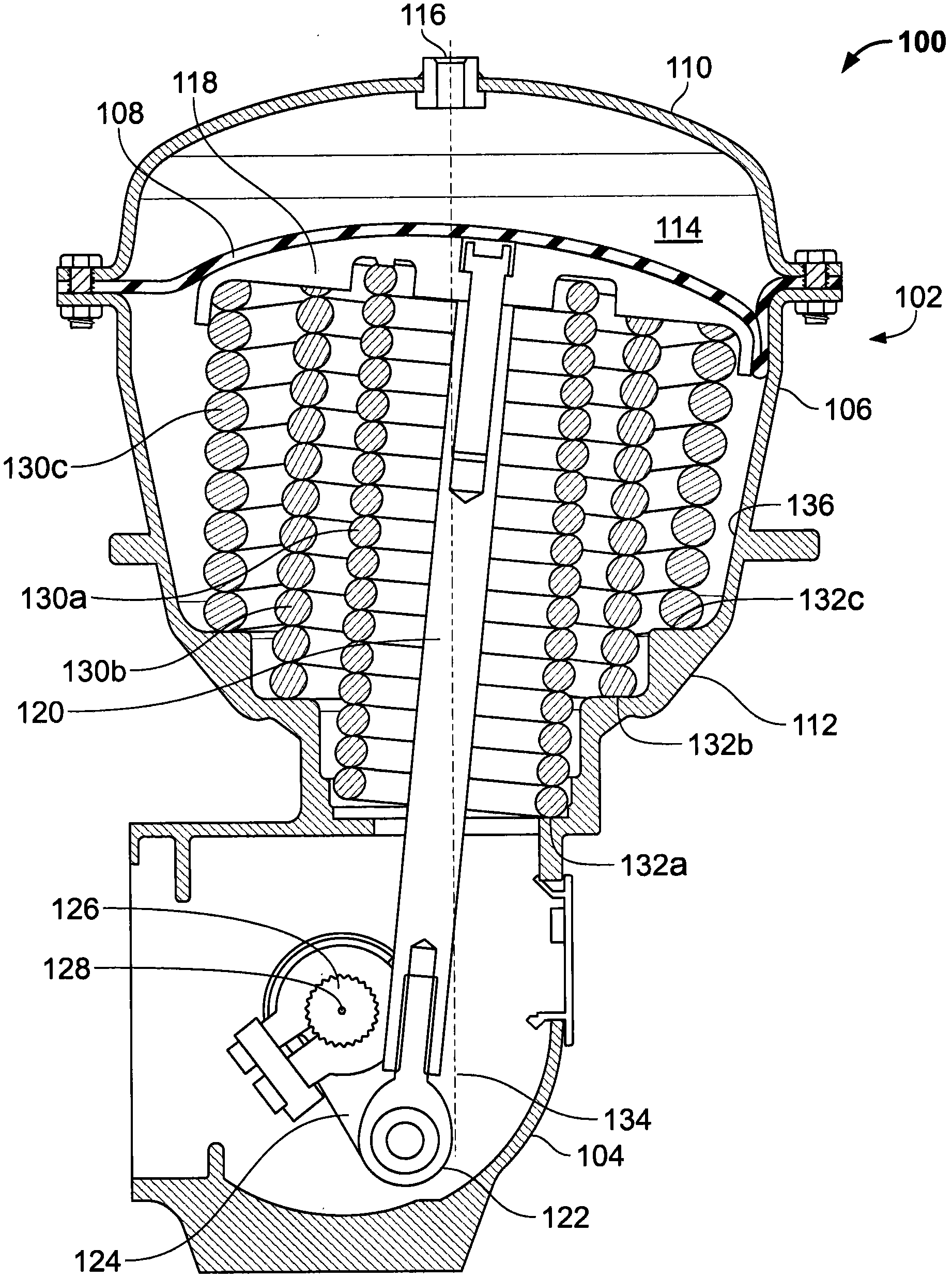

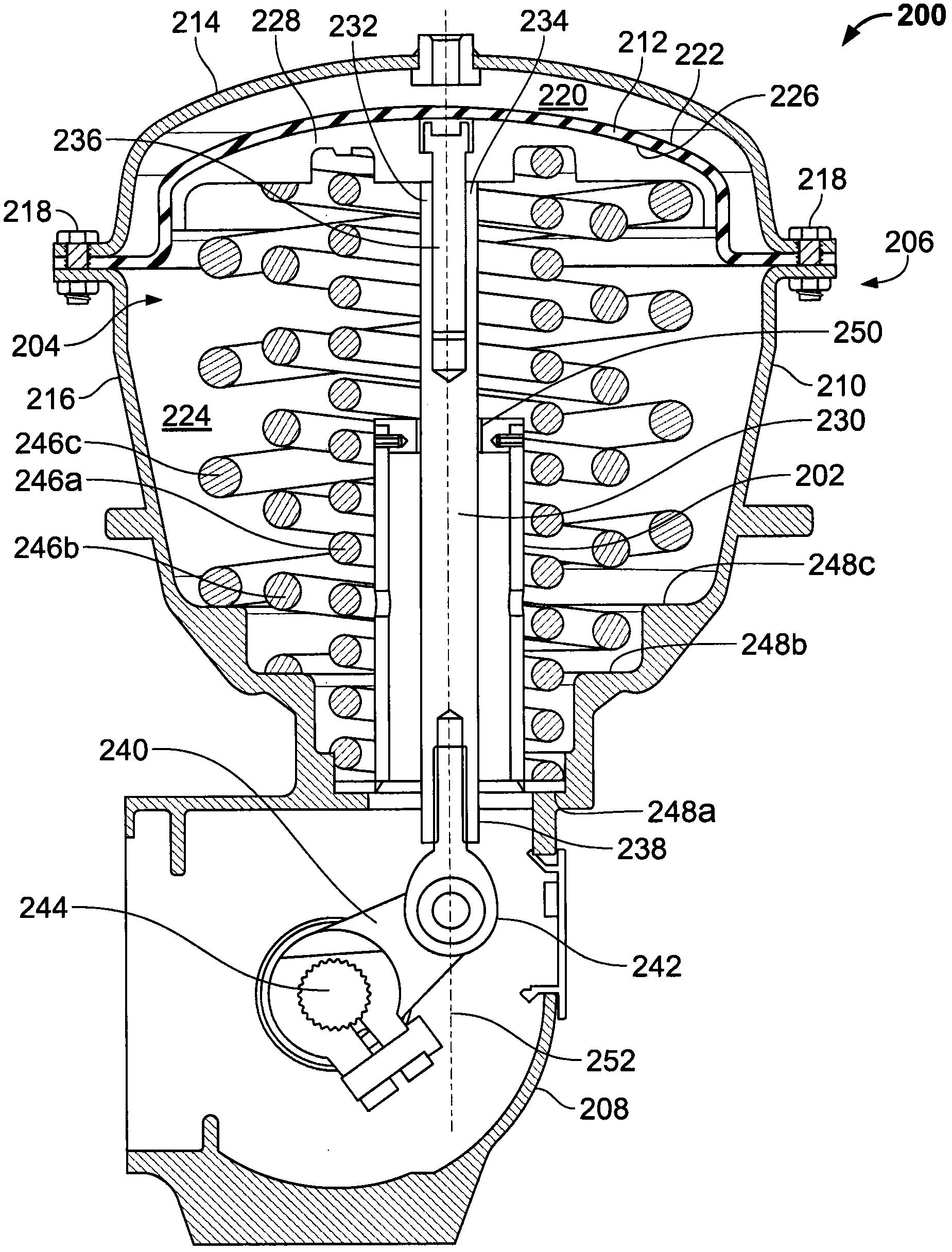

[0013] Generally, the exemplary actuator stem guides described herein prevent a fluid control valve diaphragm assembly (e.g., diaphragm and / or diaphragm plate) from contacting or engaging an interior surface or sidewall of the actuator housing to Prevents actuator degradation and / or damage to the diaphragm assembly during operation. In particular, an exemplary actuator rod guide may include a housing disposed within the actuator housing that includes an aperture or bearing surface to slidably receive and / or guide the actuator rod. In one embodiment, at least a portion of the actuator rod guide housing and / or the bearing surface is made of a material such as Delrin (Delrin), polytetrafluoroethylene (PTFE), ultra-high molecular weight polyethylene (UHMWPE) and other low friction materials to reduce friction when the actuator rod slides relative to the actuator rod guide. In operation, the actuator rod guide applies a force to the actuator rod, thereby guiding and / or substantial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com