Air pressure circuit of tire testing device, tire testing device, and tire testing method

A test device and tire technology, applied in the direction of automobile tire testing, etc., can solve the problems of unrealistic adjustment, low responsiveness, and high price of tire test device, and achieve the effect of suppressing air pressure fluctuation and high-precision test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

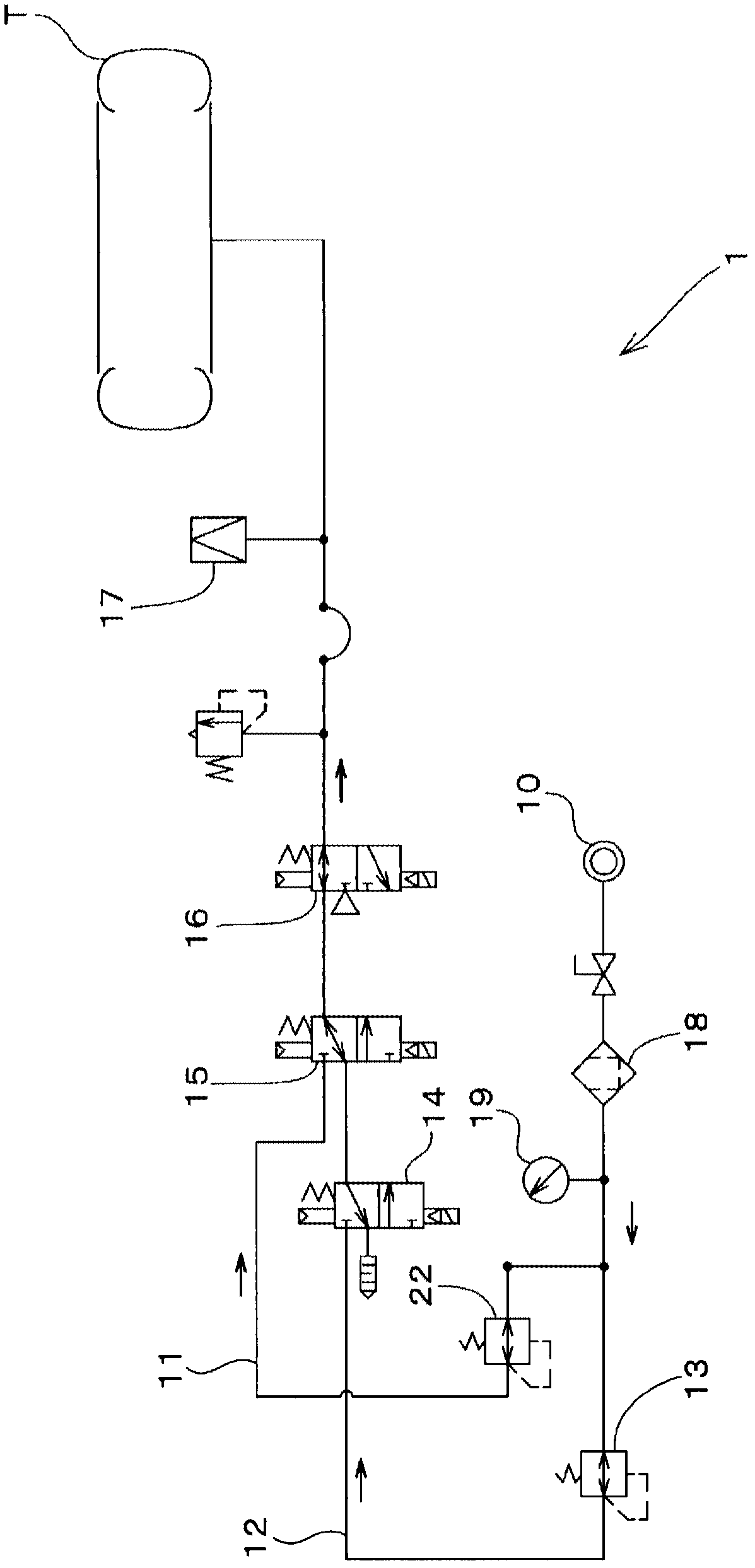

[0042] A pneumatic circuit 1 and a tire testing device 2 provided with the pneumatic circuit 1 according to the first embodiment will be described with reference to the drawings.

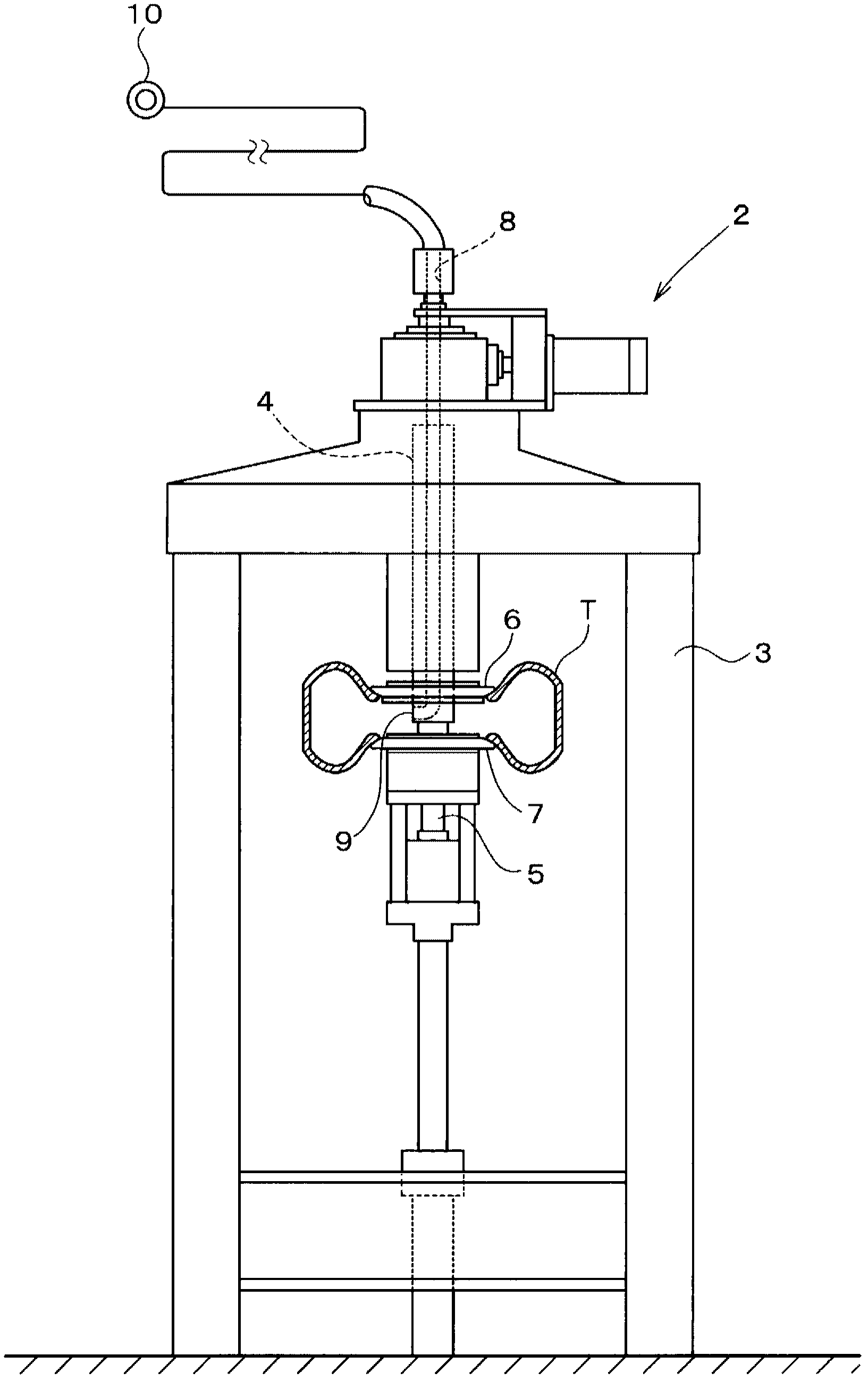

[0043] The tire testing device 2 of the present invention performs product inspection such as a uniformity test on the tire T completed in the form of a product. In this embodiment, a uniformity machine is used as the tire testing device 2 . This tire testing device 2 has, for example, figure 1 configuration as shown.

[0044] Such as figure 1 As shown schematically, the tire testing device 2 includes a frame 3 arranged in a tower shape on the ground, a set of upper and lower tire shafts 4, 5 installed on the frame 3, and a tire T fixed on these tire shafts 4, 5. The rims 6, 7. These tire shafts 4, 5 are provided rotatably around the vertical shaft. In addition, on the side of the tire T fixed by the rims 6 and 7, a roller (not shown) whose outer peripheral surface forms a simulated road surfac...

no. 2 Embodiment approach

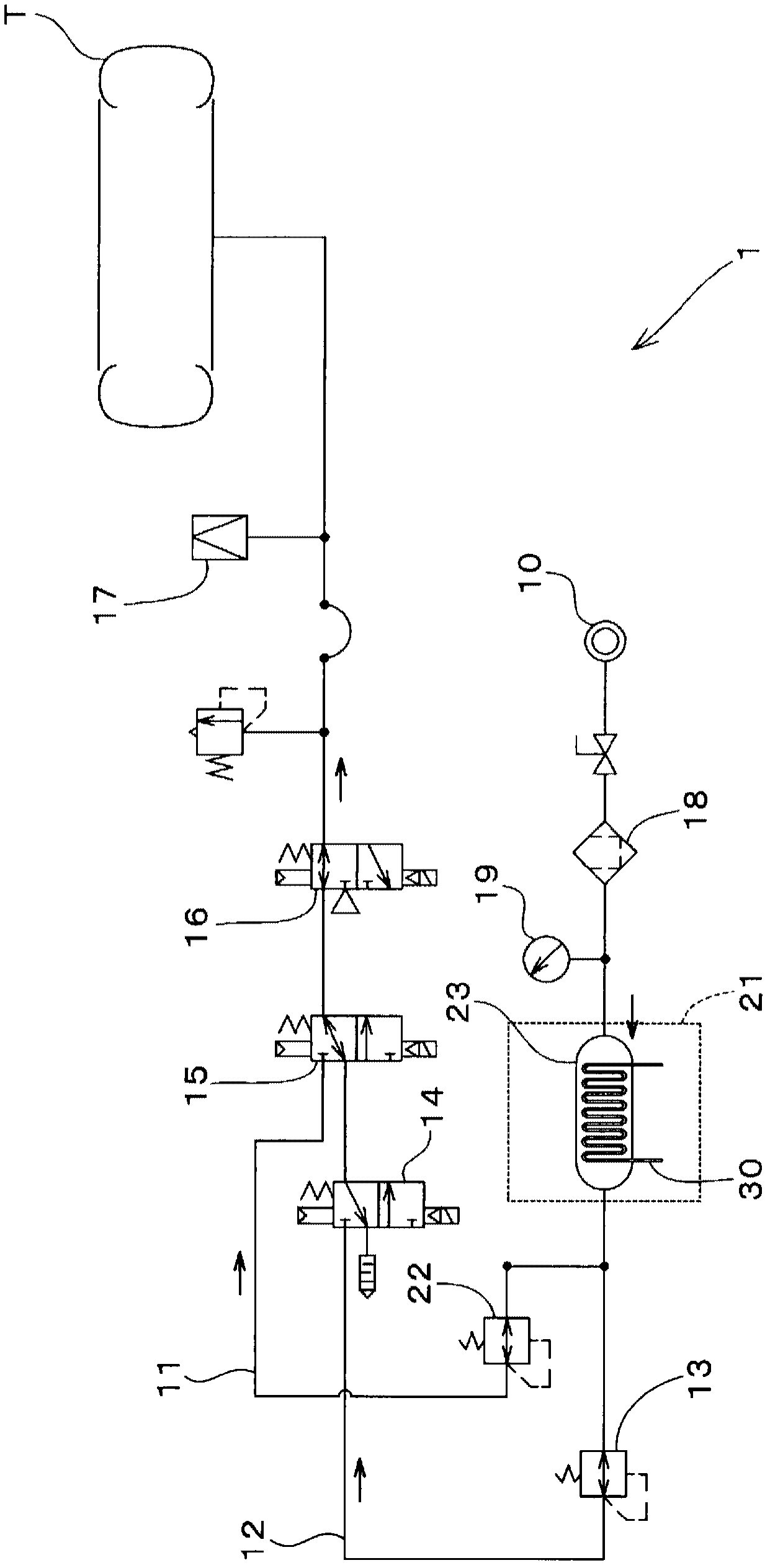

[0105] Next, the pneumatic circuit 1 of the second embodiment and the tire testing device 2 including the same will be described.

[0106] Such as Figure 4 As shown, the pneumatic circuit 1 of the second embodiment differs from the first embodiment in that it includes an exhaust unit 24 as the air temperature adjustment mechanism 21 . The exhaust unit 24 exhausts the air in the storage tank 23 to the outside before supplying it to the tire T at the bead pressure to cause adiabatic expansion.

[0107] In addition, in the air pressure circuit 1 according to the second embodiment, the air supply source 10 can supply air at a pressure (for example, about 800 kPa) higher than the bead air pressure.

[0108] The air temperature adjustment mechanism 21 includes a storage tank 23 disposed downstream of the pressure gauge 19 and upstream of a branch point of the bead seat system 11 and the test system 12 . The storage tank 23 is provided with a relief valve 33 via a shutoff valve 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com