Novel integrated sole and processing technology thereof

A processing technology, integrated technology, applied in the field of shoes, can solve the problems affecting the comfort and life of shoes, easy to open, etc., and achieve the effect of long service life and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

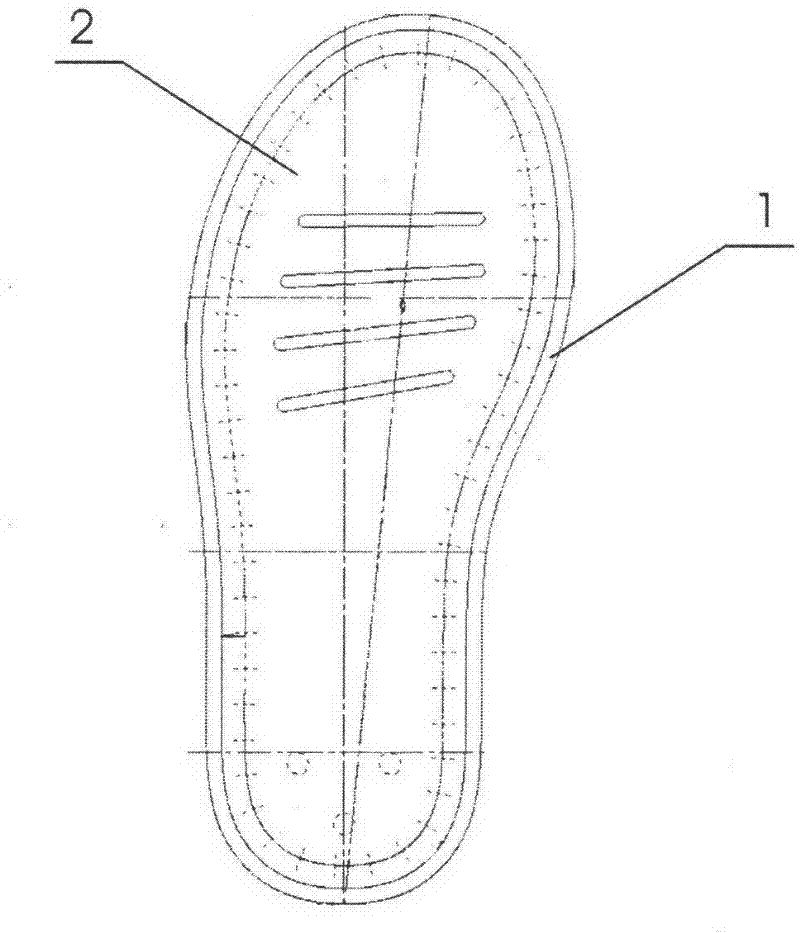

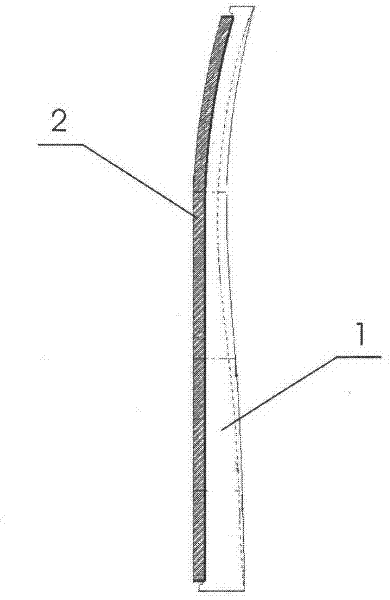

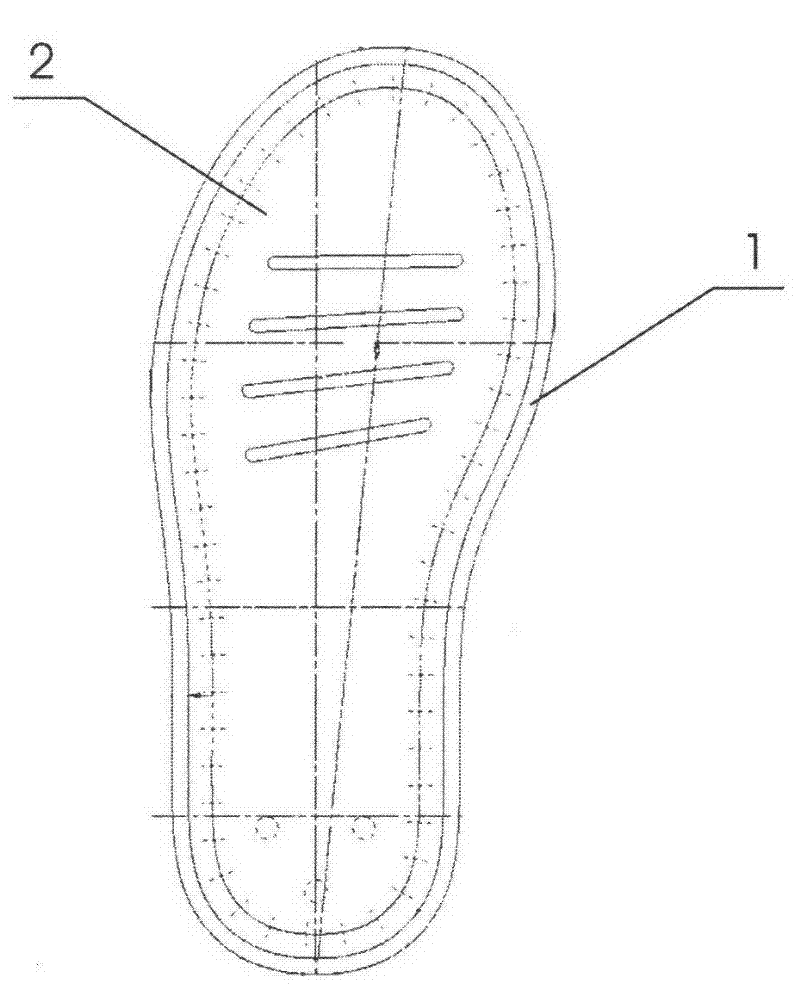

[0023] exist figure 1 and figure 2 Among them, the present invention adopts EVA1 and rubber 2 to be closely connected and molded by hot pressing.

[0024] Processing technology of the present invention is as follows:

[0025] a. First process the rubber part, put the above rubber formula into the large roller machine for rubber mixing, then put it into the small roller machine for fine rubber mixing, and then vulcanize the rubber mixing. Cut the material according to the size and thickness of the mold; heat the mold, put the rubber material into the mold at a constant temperature of 150-160 degrees, (multi-color outsole, first press the color material with the mold color separation plate, and then clean the excess part Then put the original color material), cover the mold upper cover and push it into the machine; the hot pressing molding tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com