Silicon hydrogel with medium water content and high oxygen permeability and silicon hydrogel contact lenses

A silicone hydrogel, high oxygen permeability technology, used in glasses/goggles, instruments, optics, etc., to achieve the effect of large oxygen permeability coefficient, high transparency, and soft lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The specific preparation steps of the medium water content and high oxygen permeable silicon hydrogel contact lenses provided in this example are as follows:

[0032] Mix and stir 2g of MCR-M11, 1.3g of TRIS, 1.5g of SIMAA2, 0.1g of EGDMA, 0.1g of azobisisobutyronitrile, 4g of HEMA, 6g of NVP, and 5g of n-hexanol for more than 30min, inject In the contact lens mold, thermally initiates polymerization to obtain a silicone hydrogel contact lens lens.

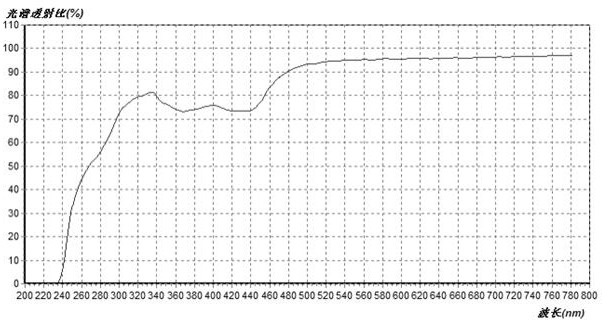

[0033] The above lenses are optically clear with a water content of 55% and a light transmission of 94.6% (see figure 1 ), the oxygen permeability coefficient DK value is 88.

Embodiment 2

[0035] The specific preparation steps of the medium water content and high oxygen permeable silicon hydrogel contact lenses provided in this example are as follows:

[0036] 1.32g of MCR-M11, 2g of TRIS, 1.5g of SIMAA2, 0.08g of EGDMA, 0.1g of azobisisobutyronitrile, 4g of HEMA, 6g of NVP, 5g of hydroxyethyl methacrylate (HEMA ), 5 g of n-hexanol were mixed and stirred for more than 30 minutes, injected into a contact lens mold, and thermally induced to polymerize to obtain a silicone hydrogel contact lens lens.

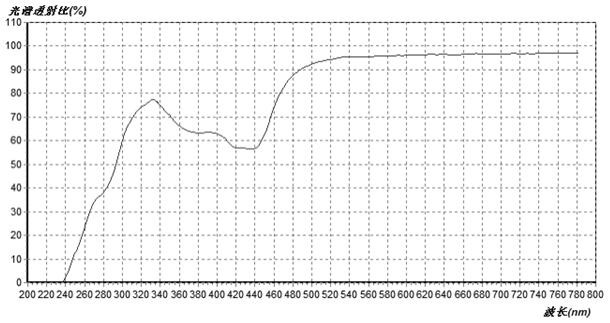

[0037] The above lenses are optically clear with a water content of 56% and a light transmission of 95% (see figure 2 ), the oxygen permeability coefficient DK value is 87.

Embodiment 3

[0039] The specific preparation steps of the medium water content and high oxygen permeable silicon hydrogel contact lenses provided in this example are as follows:

[0040] Mix and stir 1g of MCR-M11, 2g of TRIS, 1.5g of SIMAA2, 0.1g of TEGDMA, 0.1g of azobisisobutyronitrile, 4g of HEMA, 4g of NVP, and 6.3g of n-butanol for more than 30min. The method is injected into a contact lens mold, and irradiated with ultraviolet light to initiate polymerization to obtain a silicone hydrogel contact lens lens.

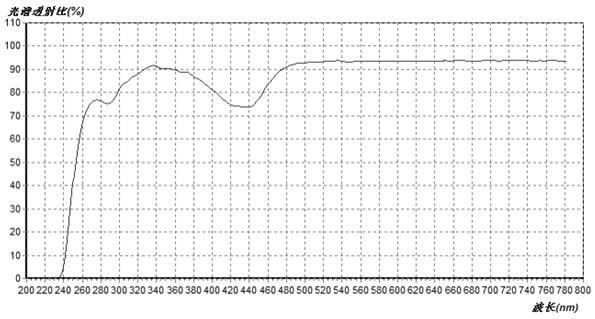

[0041] The above lenses are optically clear with a water content of 55% and a light transmission of 93% (see image 3 ), the oxygen permeability coefficient DK value is 88.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com