Microcomputer steam hotpot device

A microcomputer and hot pot technology, which is applied in heating devices, steam generation, steam generation methods, etc., can solve the problems of excessively long pipelines, unsafe, difficult to adjust, etc., and achieve the effect of reducing operating costs, high degree of automation, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

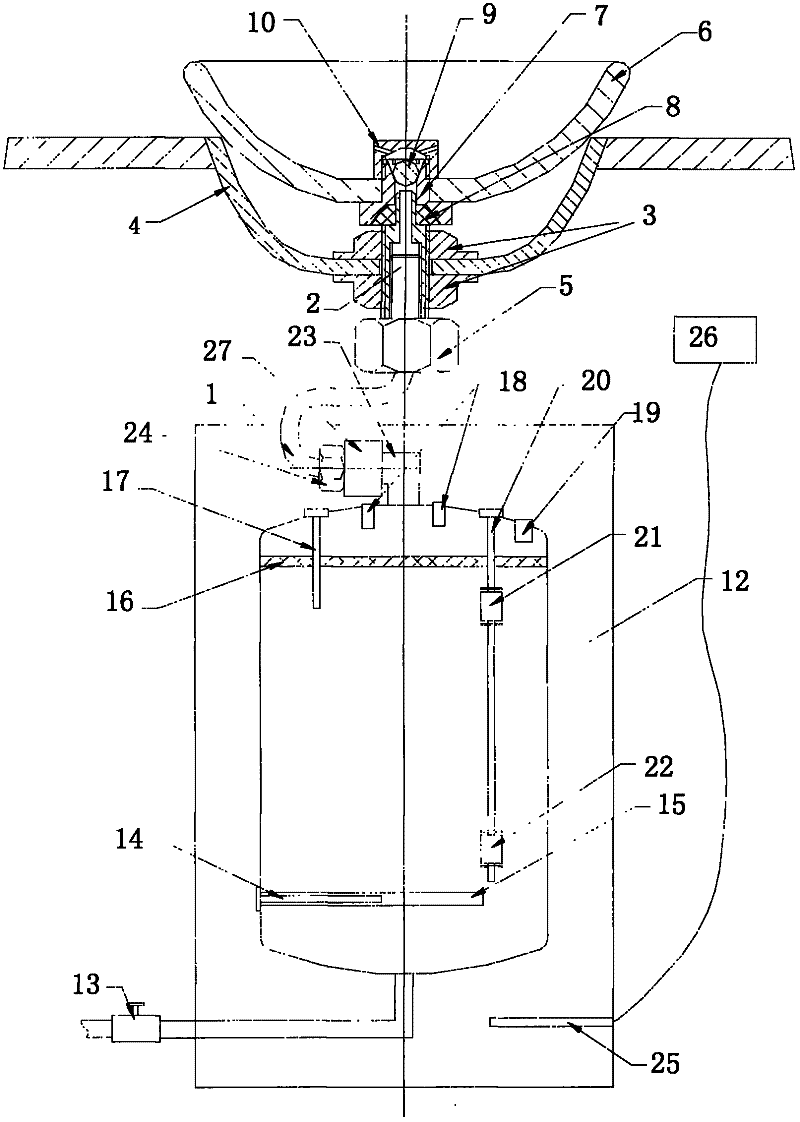

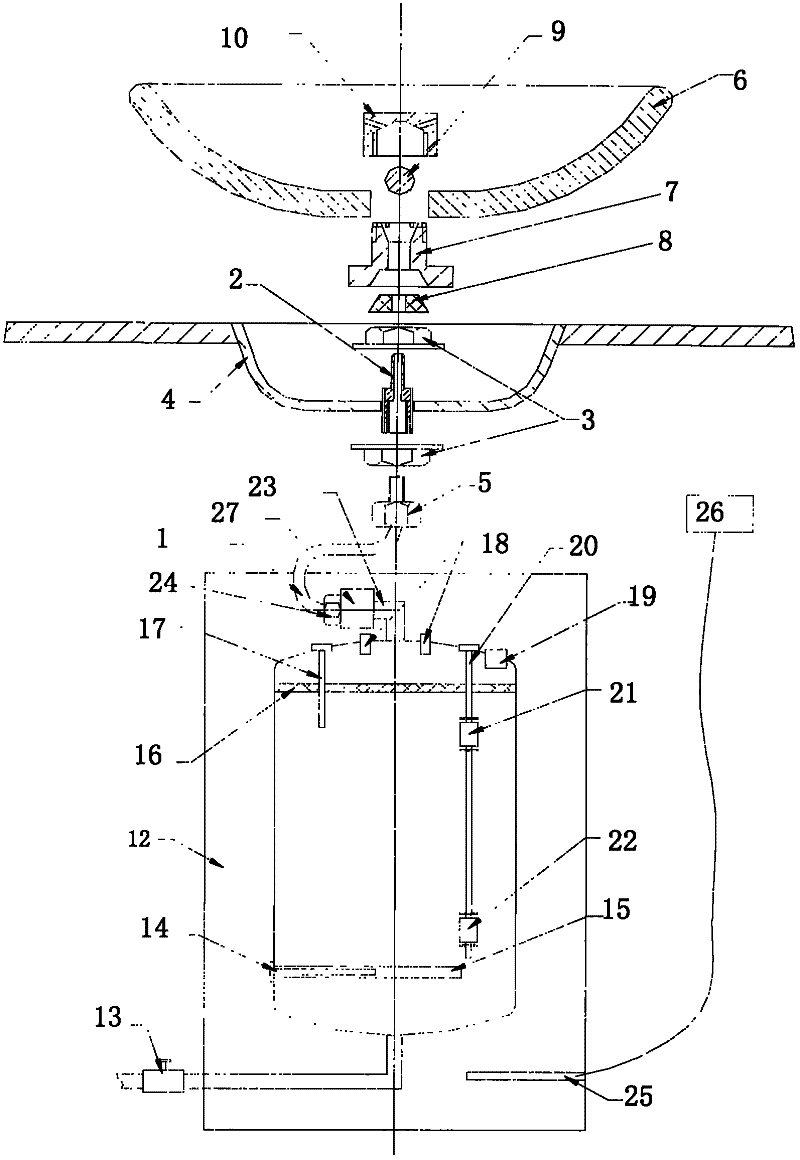

[0023] The microcomputer steam hot pot device of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

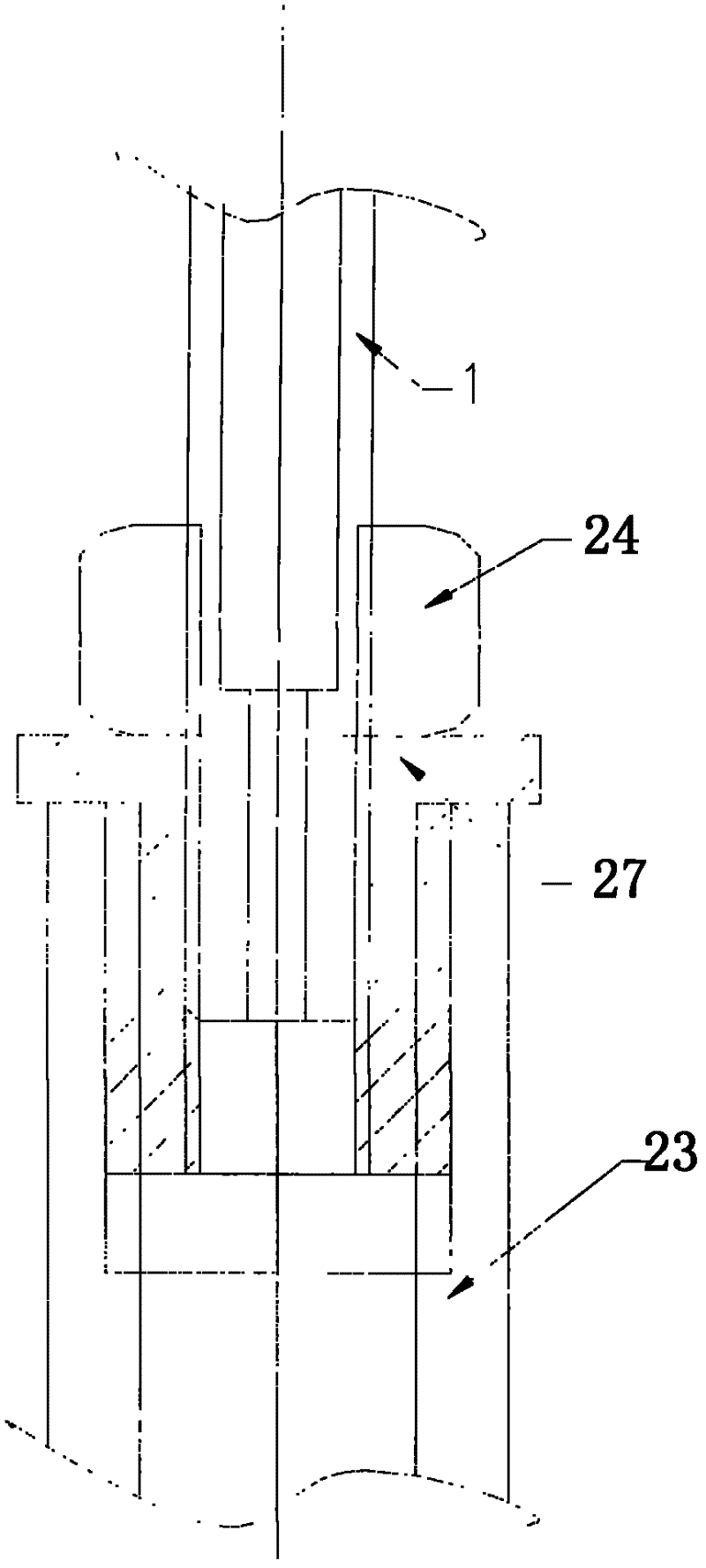

[0024] as attached figure 1 , 2 As shown, a microcomputer steam chafing dish device includes a steam oven controlled by a microcomputer. The top of the steam oven is connected to the nozzle base 2 through an output copper pipe 1, and the nozzle base 2 is fixed in the chafing dish base 4 through the nozzle adjustment nut 3. The output copper pipe joint 5 is connected between the nozzle base 2 and the output copper pipe 1. The top of the nozzle base 2 is inserted into the nozzle upper seat 7 at the bottom of the pot body 6. The bottom of the nozzle upper seat 7 is provided with a rubber pad 8, and the top is A check ball 9 is provided, and a six-hole nozzle cover 10 is fastened above the nozzle upper seat 7 .

[0025] as attached Figure 4 , 5 As shown, the six-hole nozzle cap 10 includes a nozzle cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com