Safe silica gel glass feeding bottle and production process thereof

A production process and baby bottle technology, applied in the direction of rubber layered products, feeding bottles, layered products, etc., can solve problems such as easy to burn hands, injuries, and difficult to clean, so as to improve the safety of use, personal safety, and reduce safety. The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples.

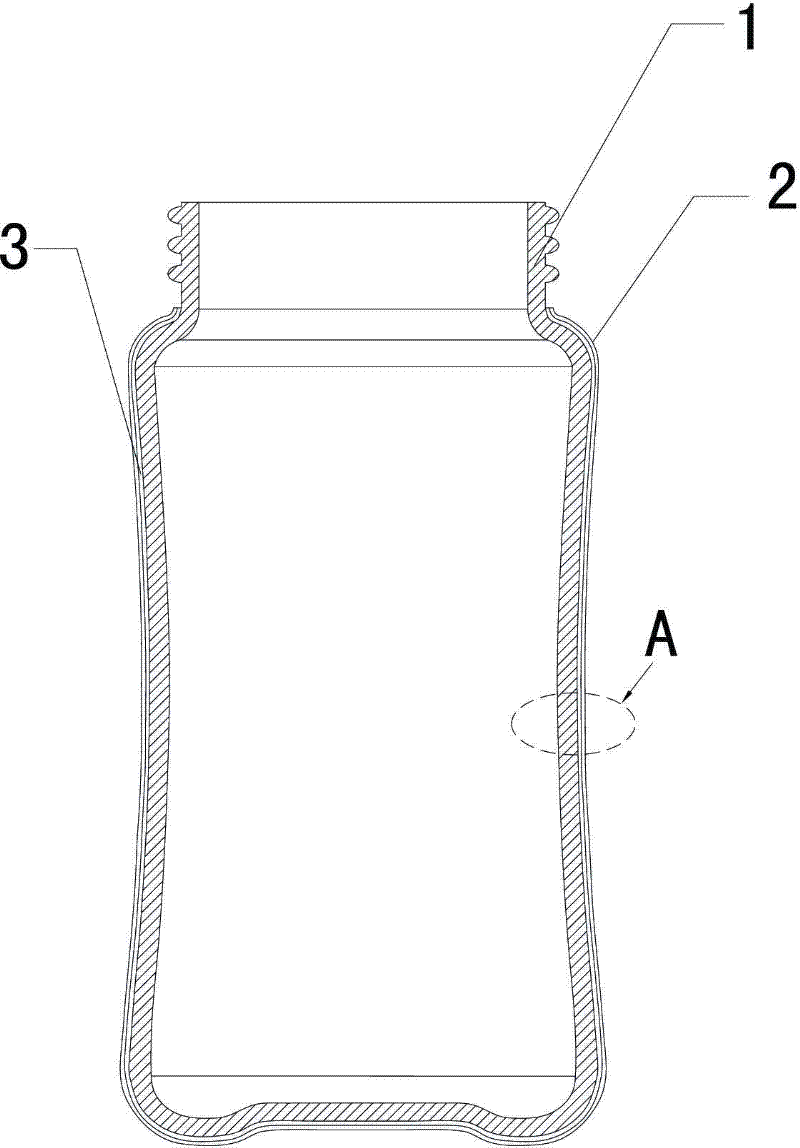

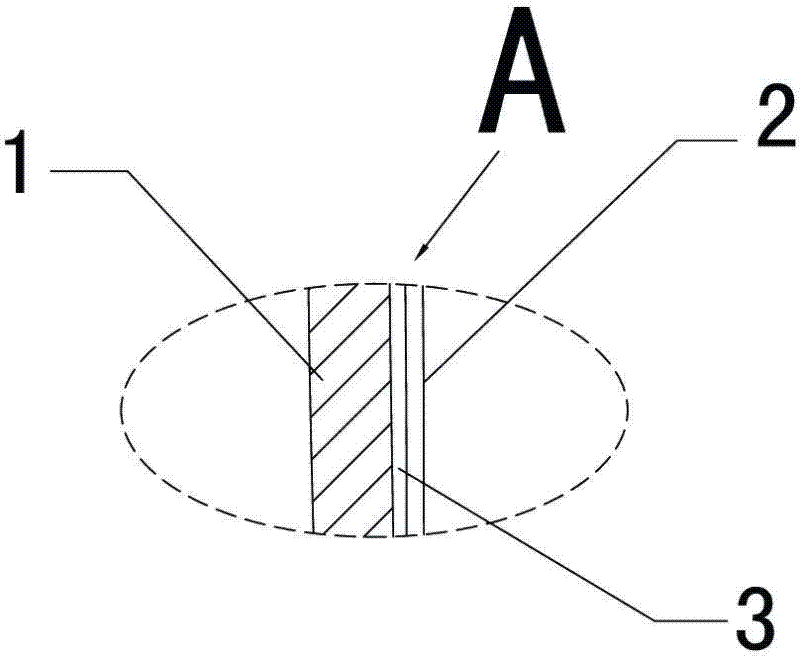

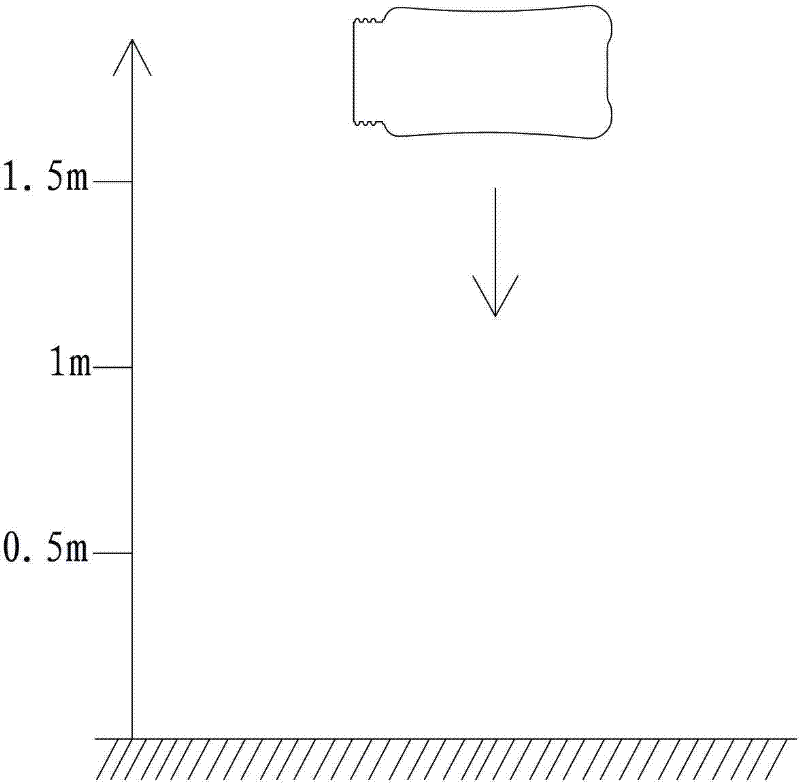

[0018] According to attached figure 1 And attached figure 2 As shown, the safety silica gel glass feeding bottle described in this embodiment includes a glass feeding bottle body 1, and a layer of silica gel protective coating 2 is sprayed on the outer surface of the feeding bottle body 1. A layer of glass-silicon bonding layer 3 is arranged between the body 1 and the silica gel protective coating 2 . And the thickness of the silica gel protective coating 2 described in this embodiment is about 0.1~0.3mm, and described glass-silicon bonding layer 3 is glass-silicon bonding material, is mainly made of silicone resin, silicon dioxide, toluene, The mixture A composed of silane coupling agent is mixed with the mixture B composed of toluene and metal coupling agent, wherein, the mixture A is composed according to the following weight percentage: silicone resin is 5-12%, two Sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com