Supporting apparatus for flue gas denitration reactor

A technology of denitrification reactor and supporting device, which is applied in the field of denitrification reactor, can solve the problems of uneven load distribution, achieve the effect of maintaining linear and uniform load distribution, improving adaptability, and improving high temperature adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

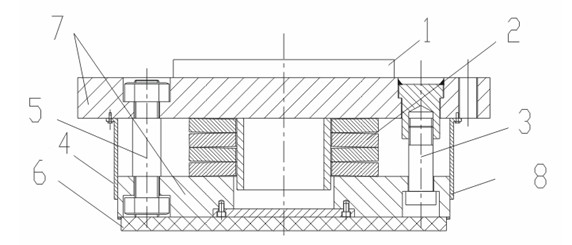

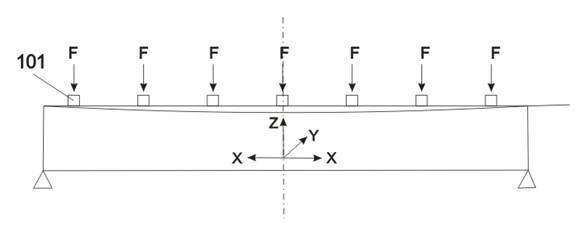

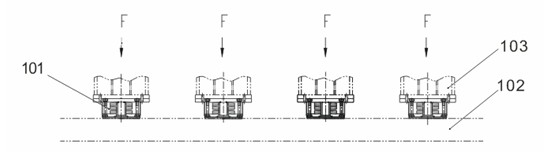

[0033] like figure 1 As shown, a supporting device body 101 is included, and a rainproof cover 4 is provided outside the supporting device body 101 . The support device body 101 includes a bracket 7 with an upper and lower bottom plate, a locking rod 3, a limit rod 5, a butterfly spring 2 and a displacement indicator 8, and a ceramic heat insulating gasket 1 is arranged on the upper bottom plate of the bracket 7, A PTFE sliding gasket 6 (the Chinese name of PTFE is polytetrafluoroethylene, and the English name is Poly tetrafluoroethylene ptfe) is provided at the bottom of the lower bottom plate of the bracket 7 . The locking pull rod 3 is pre-fastened between the upper and lower bottom plates of the support 7. The top and bottom ends of the limit pull rod 5 are respectively provided with left and right rotation nuts, and the bottom nut has a gap with the lower bottom plate of the support 7. The butterfly spring 2 Located between the upper and lower bottom plates of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com