Pressure feedback type liquid atomization device

A liquid atomization and feedback technology, applied in the direction of liquid injection devices, injection devices, etc., can solve the problems that the liquid atomization cannot meet the requirements, the droplet atomization is insufficient, the size distribution is uneven, etc., and the atomization state can be reached control, good atomization effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

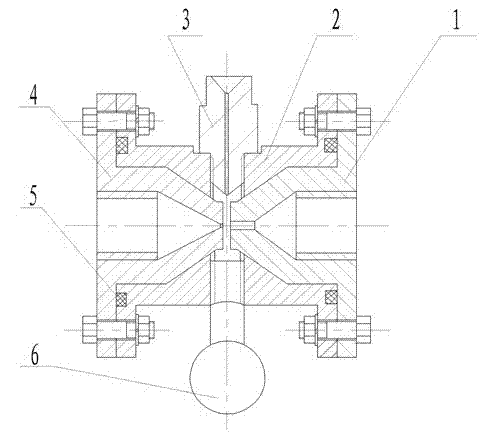

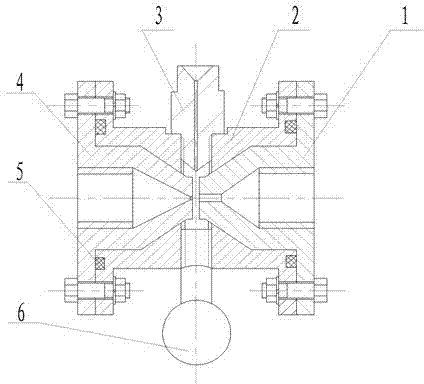

[0013] An air pressure feedback type liquid atomization device. like figure 1 As shown: the inlet nozzle 1 and the outlet nozzle 4 are installed on the same axis through the connecting body 2, the gap between the inlet nozzle 1 and the outlet nozzle 4 is 0.1 ~ 1mm, the external shape of the inlet nozzle 1 and the outlet nozzle 4 and the connecting body 2 The internal shape of the corresponding installation is the same; the air inlet plug 3 and the pressure gauge 6 are installed in the middle of the connecting body 2, the center line of the gap between the inlet nozzle 1 and the output nozzle 4, the hole center line of the inlet plug 3 and The installation center line of the pressure gauge 6 is located on the same vertical plane, the liquid inlet nozzle 1, the output nozzle 4, the air inlet plug 3 and the pressure gauge 6 communicate with each other through their respective center holes, and the connection between the liquid inlet nozzle 1, the output nozzle 4 and the connectin...

Embodiment 2

[0017] An air pressure feedback type liquid atomization device. Except following technical parameter, all the other are with embodiment 1:

[0018] The diameter of the small hole of the liquid inlet nozzle 1 is 0.3-0.5 mm, and the length of the hole is 5-10 mm; the diameter of the small hole of the output nozzle 4 is 0.3-0.5 mm, and the length of the hole is 0.5-1.0 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com