Uniaxial elliptic motion trail vibration exciter

An elliptical motion and vibration exciter technology, which is applied in chemical instruments and methods, fluid and solid separation using vibration, etc., can solve the problems of complex structure, inconvenient use and maintenance, and high cost of triaxial vibration exciters, and achieves a high level of improvement. Vibration excitation effect and efficiency, easy use and maintenance, easy transformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

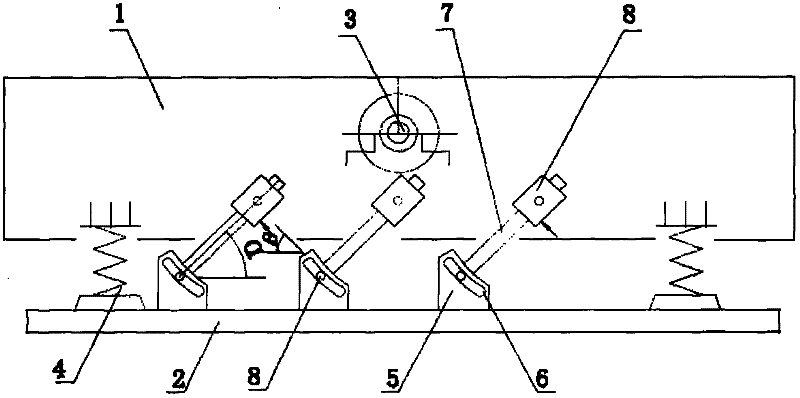

[0026] Example 1: Such as figure 1 As shown, a single-axis elliptical motion track vibration exciter includes a vibration box body 1, a base 2, an excitation spring 4, and an excitation shaft 3. The excitation shaft 3 is arranged on the vibration box body 1; the excitation spring 4 is arranged On the four corners between the vibrating box 1 and the base 2.

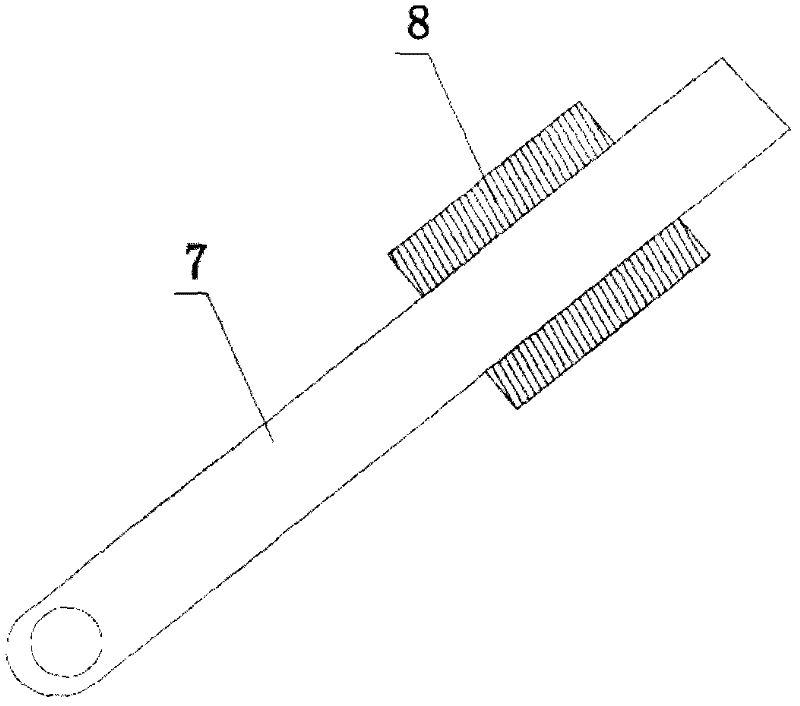

[0027] Three pairs of orbit determination mechanisms are arranged on the vibrating box 1, and each pair of orbit determination mechanisms are symmetrically arranged on both sides of the vibrating box 1. The rail fixing mechanism includes a fixed rail 7 and a sliding sleeve 8; the upper end of the rail fixing rod 7 is sleeved in the sliding sleeve 8, and the sliding sleeve 8 is hinged on the vibrating box 1, such as image 3 Shown.

[0028] The lower end of the rail rod 7 is hinged to the base 2. The base 2 is provided with a base 5, and the base 5 is provided with an arc-shaped slot 6; the lower end of the rail rod 7 and the h...

Embodiment 2

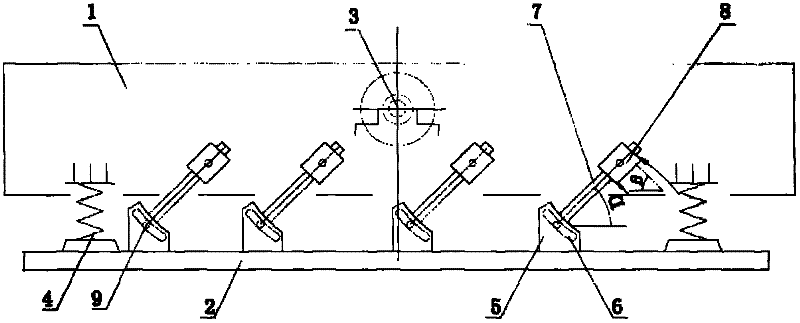

[0032] Example 2: Such as figure 2 As shown, the vibration box 1 is provided with four pairs of orbit determination mechanisms, and each pair of orbit determination mechanisms are symmetrically arranged on both sides of the vibration box 1. The orbit determination mechanism includes a fixed rail 7 and a sliding sleeve 8.

[0033] The rail fixing rods 7 on the same side of the vibration box 1 are arranged symmetrically with the longitudinal line where the fixed axis of the excitation shaft 3 is located. The rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com