Cooling water circulating system for garbage disposers

A technology for waste treatment equipment and cooling water circulation, which is applied in lighting and heating equipment, irreversible cycle compressors, refrigerators, etc. Low maintenance cost, stable cooling water circulation system, uniform cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

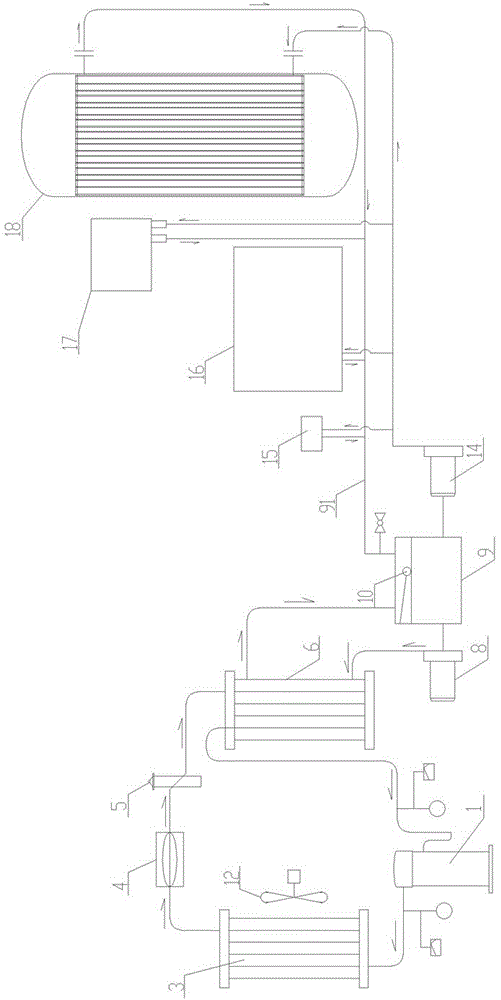

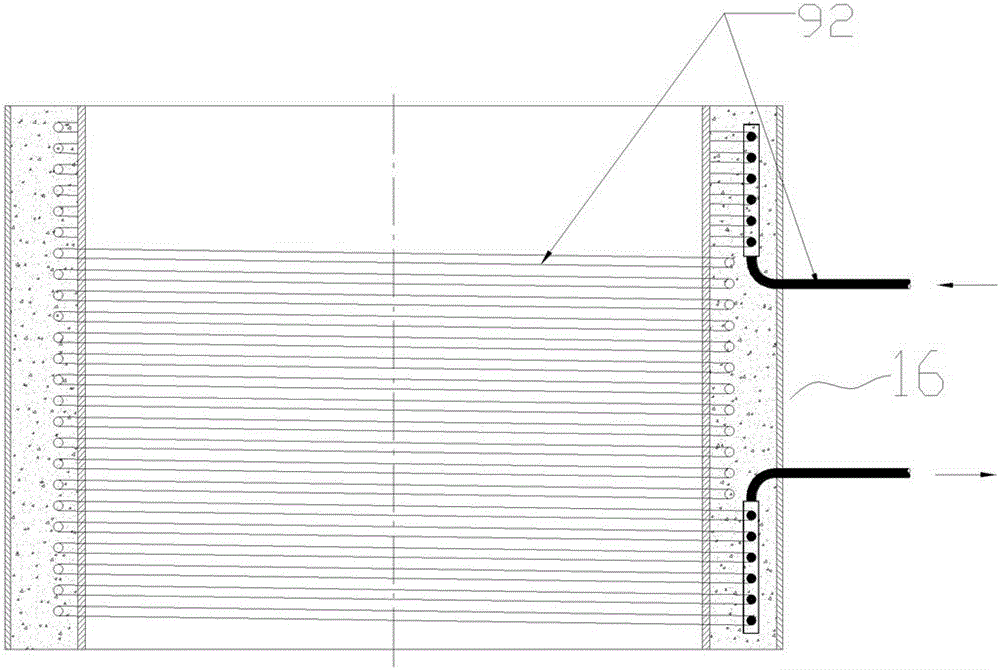

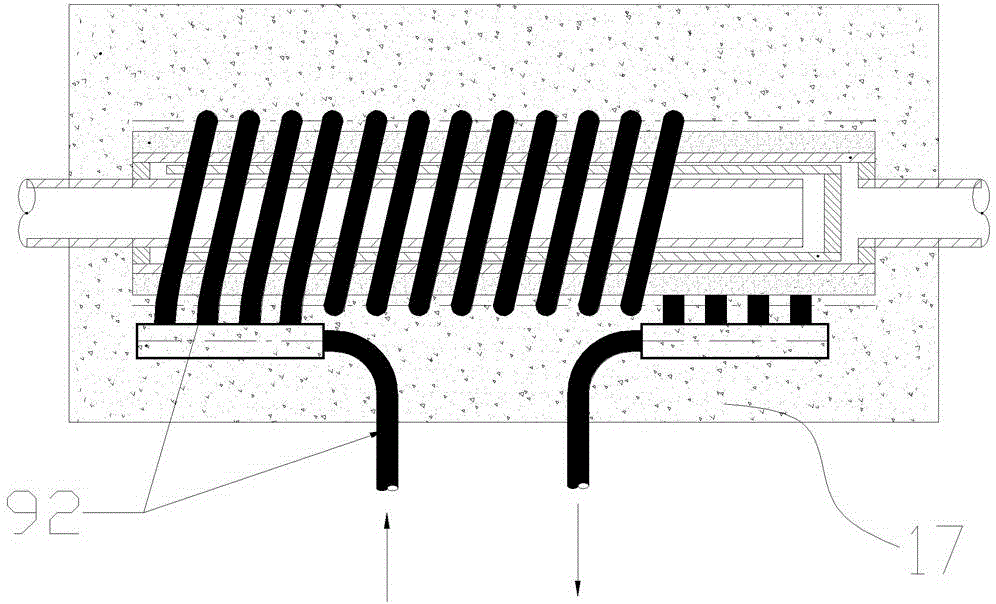

[0016] like figure 1 As shown, the present invention includes a cooling water tank 9, a refrigerant cycle device and a cooling water cycle device, and the refrigerant cycle device includes an evaporator 6, a compressor 1, a condenser 3, a dry filter 4, and an expansion valve 5 connected in sequence, One side of the condenser 3 is provided with a blower fan 12, and the cooling water circulation device includes a cooling water external circulation main pipeline 91 and some garbage disposal equipment, a cooling waterway 92 is provided in the garbage disposal equipment, and a cooling water circuit 92 is arranged in the garbage disposal equipment The cooling water circuit 92 is connected in series or in parallel with the cooling water outer circulation main pipe 91, and the cooling water tank 9 is provided with an inner circulation cooling water inlet, an inner circulation cooling water outlet, an outer circulation cooling water inlet, and an outer circulation cooling water outlet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com