Vertical closed type garbage incineration kiln

A waste incineration and closed technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve problems such as threats to human health, inability to incinerate electronic waste, endangering life safety, etc., to ensure environmental protection and safety, and guarantee personal safety. Healthy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

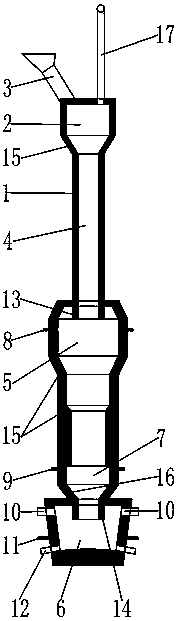

[0014] see figure 1 , the present invention provides a vertical closed garbage incineration kiln, comprising a kiln body 1, a garbage feeding bin 2 is arranged in the upper part of the kiln body 1; Garbage feed port 3; the lower part of the garbage feed bin 2 is provided with a preheating drying zone 4 connected therewith; the middle part of the kiln body 1 is provided with a pyrolysis zone 5 connected with the preheating drying zone 4; The bottom of the kiln body 1 is provided with a pure oxygen high-temperature dissolution zone 6, and the pure oxygen high-temperature dissolution zone 6 communicates with the pyrolysis zone 5 through the pure oxygen combustion zone 7; The carbon monoxide inlet 8, the carbon monoxide inlet 8 communicates with the pyrolysis zone 5; the outer wall of the kiln body 1 is provided with a number of first pure oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com