Small narrow band bending straightener

A stretch-bending straightening and narrow-belt technology, which is applied in the field of metal strip straightening equipment, can solve the problems of narrow applicable surface, inconvenient operation, complex structure, etc., and achieves convenient belt threading and operation, simple structure and good straightening effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

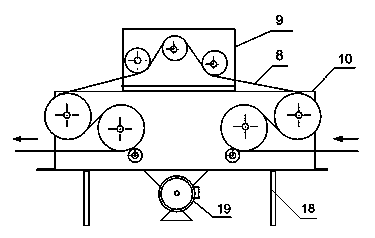

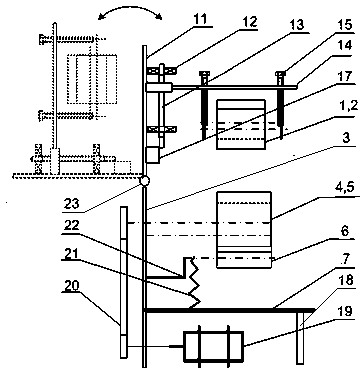

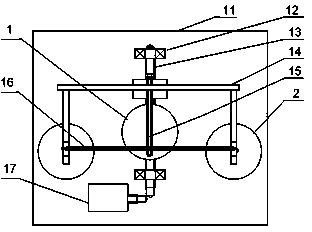

[0020] Embodiment 1: as Figure 1-4 As shown, the small-sized narrow-belt stretch-bending straightening machine is composed of a straightening roller group mechanism 9 at the upper part, a bending roller group mechanism 10 at the middle part, a lower machine base 18, a power mechanism, and a control device; the straightening roller group mechanism 9 includes a straightening roller group and its support adjustment device. The straightening roller group is composed of a straightening roller 1 and a pair of lower pressure rollers 2; the bending roller group mechanism 10 in the middle is composed of two pairs of active bending rollers 5, driven bending rollers 4 and pinch roller 6; the power mechanism includes a main drive motor 19 and a transmission mechanism 20; the active bending roll 5, the driven bending roll 4 and the pinch roll 6 are cantilevered on the base back plate 3 through their rotating shafts, straightening The roller 1 and the lower pressing roller 2 are mounted on...

Embodiment 2

[0024] Embodiment 2: as Figure 1-4 As shown, the structure of this small narrow-belt stretch bending straightening machine is the same as that of Embodiment 1, and the transmission mechanism 20 is an ordinary chain transmission mechanism with a transmission ratio of 7:1.

Embodiment 3

[0025] Embodiment 3: as Figure 1-4 As shown, the structure of this small narrow-band stretch bending straightening machine is the same as that of Embodiment 1. The transmission mechanism 20 is an ordinary gear transmission mechanism with a transmission ratio of 3:1, and the output shaft of the stepping motor 17 is connected to the lower end of the screw rod 13 through a coupling. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com