Piercing and flanging compound die

A composite mold and flanging technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the production accuracy and efficiency of parts, increasing the production cost of parts and mold manufacturing costs, and achieving production accuracy and efficiency. Lifting, versatile, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

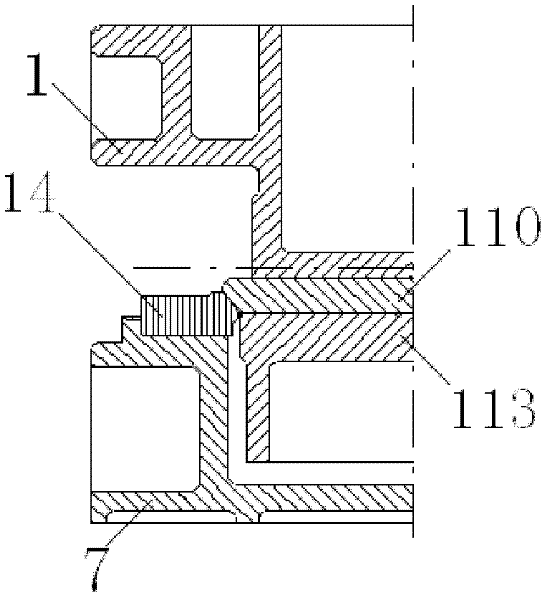

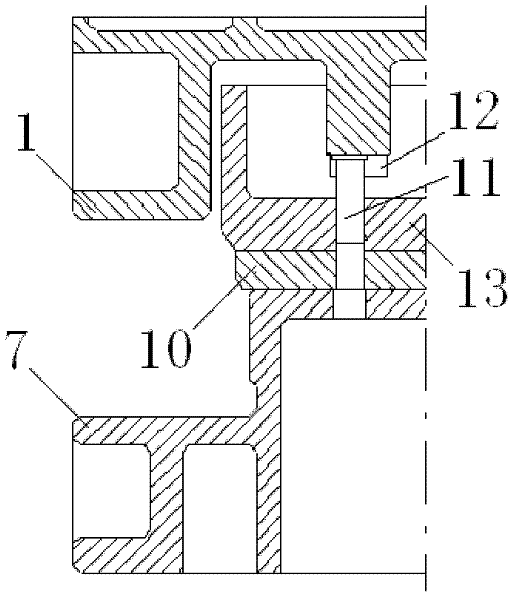

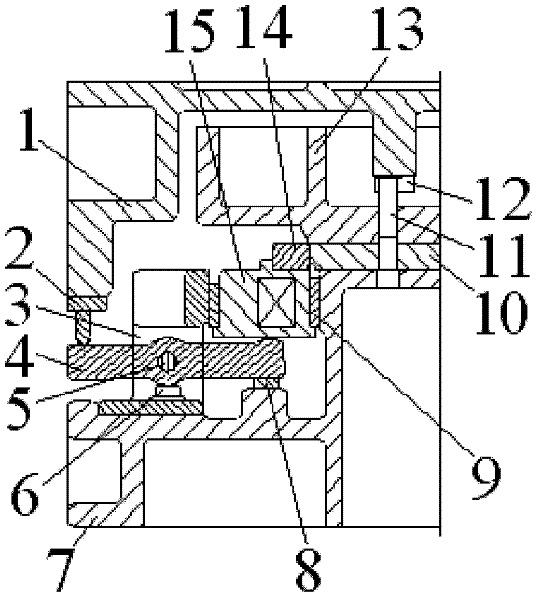

[0020] Such as figure 1 As shown, it is an existing mold for performing upper flanging operation on the sheet material. The flanging knife block is fixed on the lower mold base, and the flanging pressing plate 113 is arranged on the lower mold base through a spring, and the upper mold base and the flanging pressing material A flanging lower mold cutter block 110 is arranged between the plates 113. During operation, the upper die base drives the flanging pressing plate to move downwards, so that the flanging cutter block performs flanging processing on the sheet material. Such as figure 2 As shown, it is an existing die for punching sheet metal. The punch is fixed on the upper die base through the punch fixing plate, and the pressing plate is set on the upper die base. When working, the plate is firstly positioned. The upper die base moves downward, driving the punch to move downward, the clamping plate presses the plate, and the punch passes through the plate to complete the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap