Circle shearing machine capable of determining width and smashing edges of lead belt for storage battery

A battery and disc shear technology, applied in shearing machine equipment, shearing device, metal processing equipment and other directions, can solve the problem of lead strip waste edge introduction and other problems, and achieve the effect of convenient installation and debugging, less investment and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

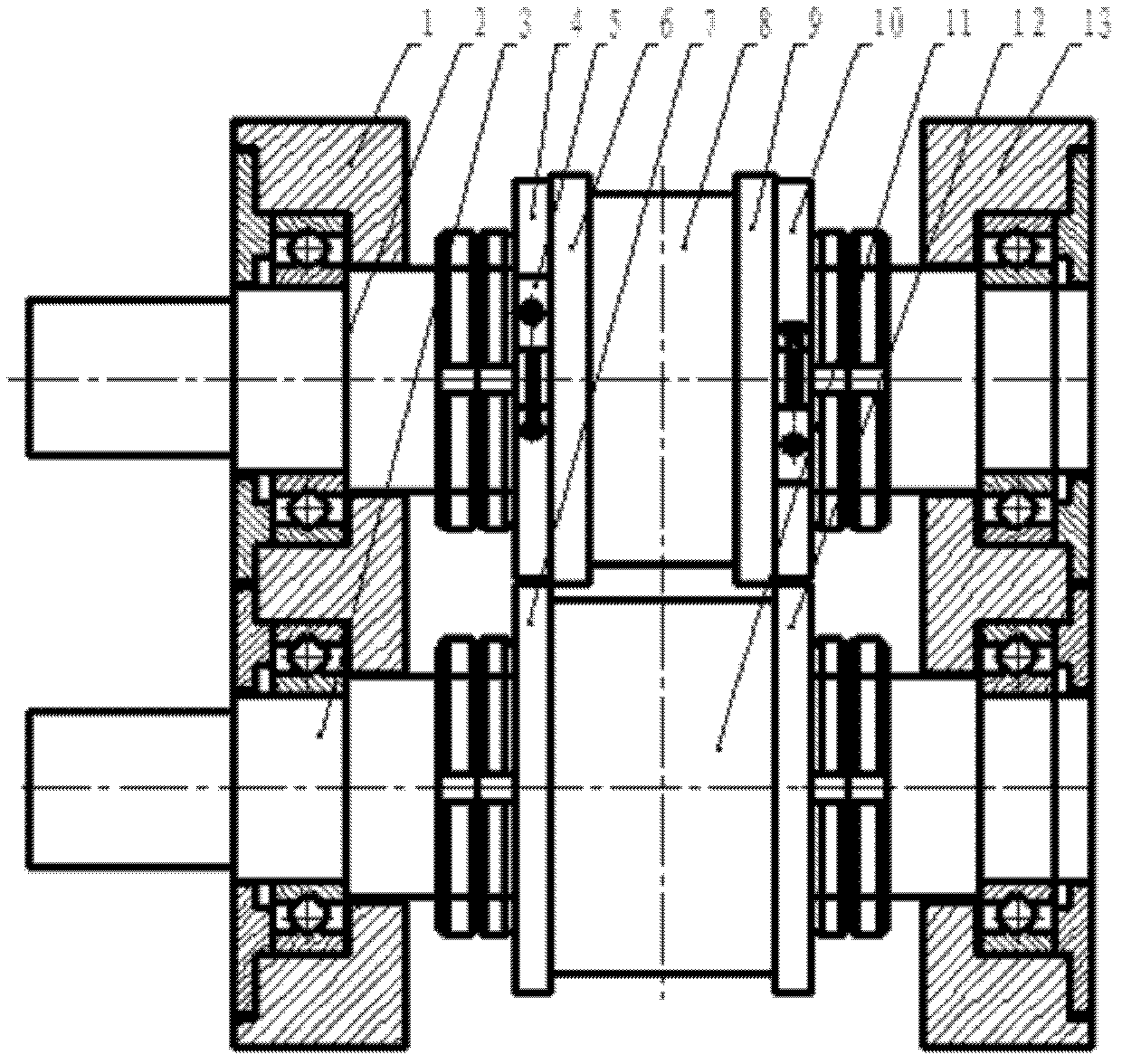

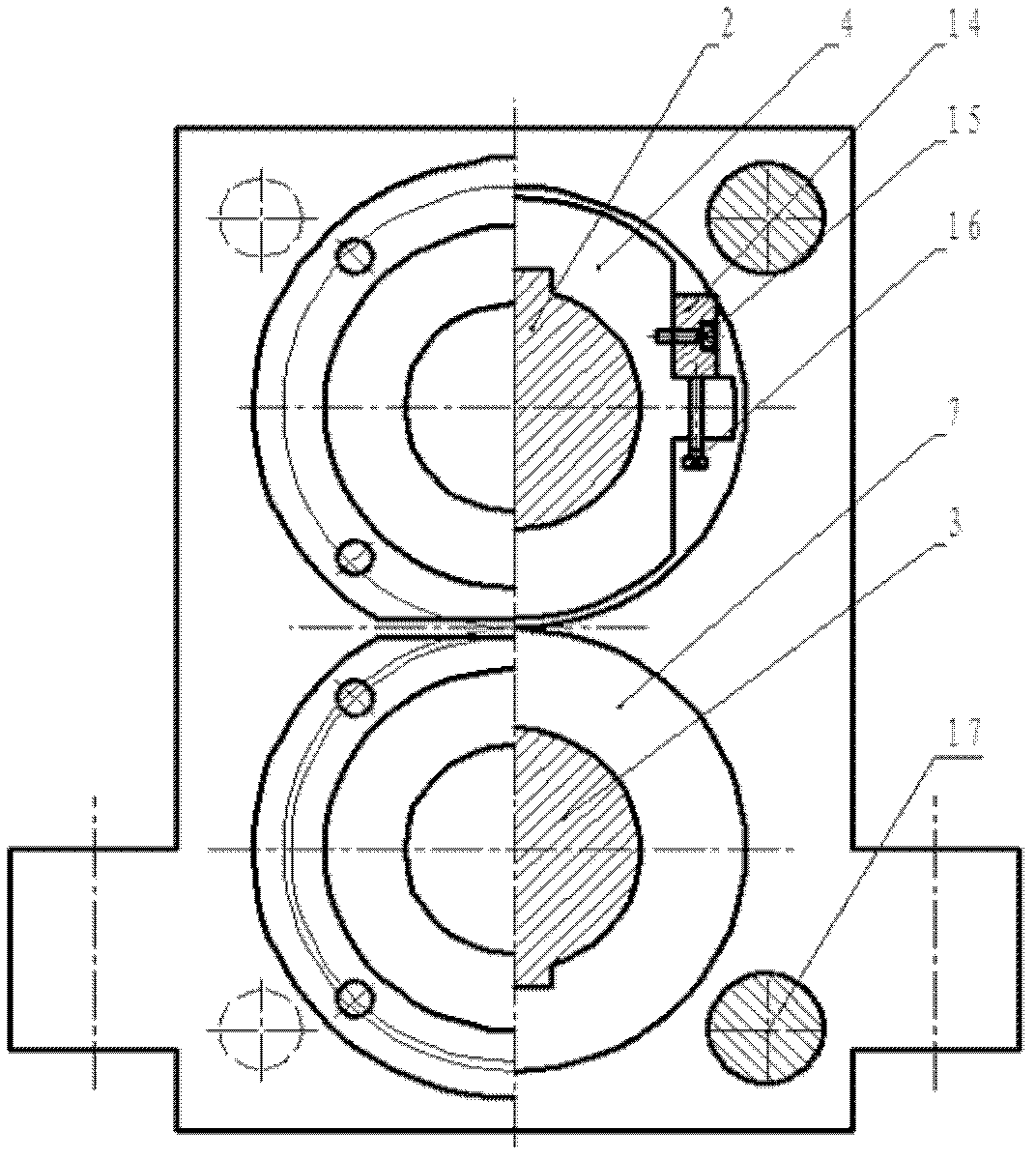

[0028] Disclosed is a disc shearing machine for fixing the width and cutting edges of lead belts for storage batteries. The lead belt for the storage battery is a lead-calcium alloy belt, and its thickness h is 2mm. The disc shears such as figure 1 , figure 2 As shown, the upper cutter shaft 2 and the lower cutter shaft 3 of the disc shears are respectively installed in the left frame 1 and the right frame 13 through bearings, and the left frame 1 and the right frame 13 are connected by a crossbeam 17 . The installation positions of the upper cutter shaft 2 and the lower cutter shaft 3 are parallel to each other, the upper cutter shaft 2 is installed above the frame, and the lower cutter shaft 3 is installed below the frame.

[0029] Such as figure 1 As shown, the upper knife shaft 2 is equipped with an upper width adjustment part 8, and the right side close to the upper width adjustment part 8 is fixedly equipped with an upper right blade 9, a right knife seat 10, a sprin...

Embodiment 2

[0042] Disclosed is a disc shearing machine for fixing the width and cutting edges of lead belts for storage batteries. Except following structure and technical parameter, all the other are with embodiment 1:

[0043] The upper cutter shaft 2 is installed below the frame, and the lower cutter shaft 3 is installed above the frame.

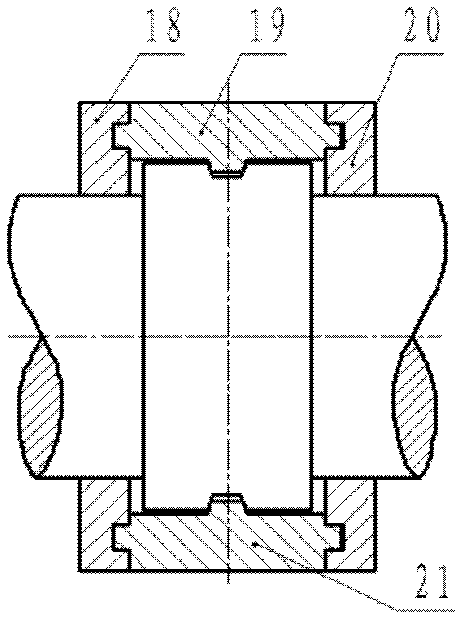

[0044] There is one piece of left scraping knife 5 and right scraping knife 14; the blade radius r of left scraping knife 5 and right scraping knife 14 碎 same. In this embodiment, the knife edge radius r 碎 Satisfies the following formula:

[0045] r 碎 =s-r 下 -(0.02~0.2)h

[0046] In the formula: s is the axial distance between the upper cutter shaft 2 and the lower cutter shaft 3, s=90mm;

[0047] r 下 is the radius of the lower left blade 7 and the lower right blade 12, r 下 =45mm;

[0048] h is the thickness of the sheared material, h=0.9mm.

[0049] The axial gap between the right side of the lower left blade 7 and the left side of the upp...

Embodiment 3

[0052] Disclosed is a disc shearing machine for fixing the width and cutting edges of lead belts for storage batteries. Except following parameter, all the other are with embodiment 1:

[0053] There are 3 to 4 pieces of the left scraping knife 5 and the right scrapping knife 14; the radius r of the right scraping knife 14 is 碎 The blade radius r of the left scraping knife 14 碎 same. In this embodiment, the knife edge radius r 碎 satisfy the following formula

[0054] r 碎 =s-r 下 -(0.02~0.3)h (1)

[0055] In the formula (1): s is the axial distance between the upper cutter shaft 2 and the lower cutter shaft 3, s=300mm;

[0056] r 下 is the radius of the lower left blade 7 and the lower right blade 12, r 下 =150mm;

[0057] h is the thickness of the sheared material h=4.0mm.

[0058] The axial gap between the right side of the lower left blade 7 and the left side of the upper left blade 6 is 0.2~1.0mm, and the axial gap between the left side of the lower right blade 12 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com