Automatic metal substrate feeding device

An automatic feeding device and metal substrate technology, applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of unguaranteed processing quality, low production efficiency, simple structure, etc., and achieve good feeding effect, stable position, and simple control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

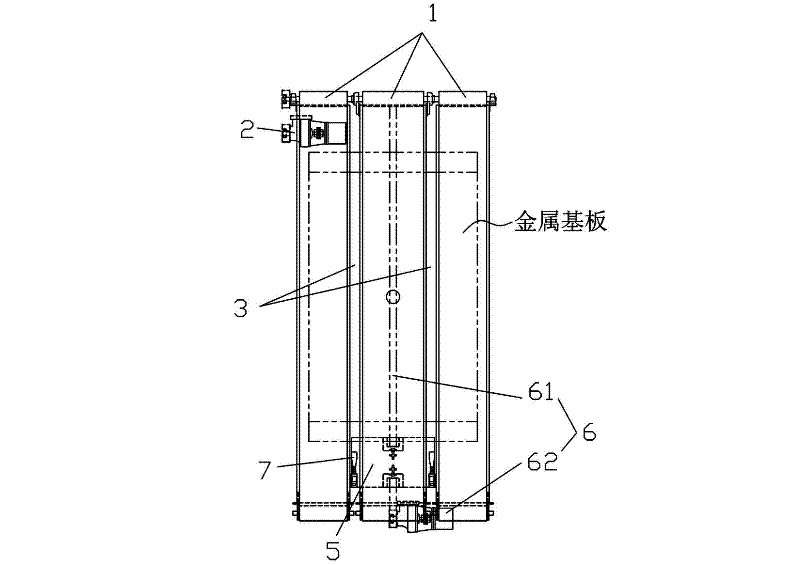

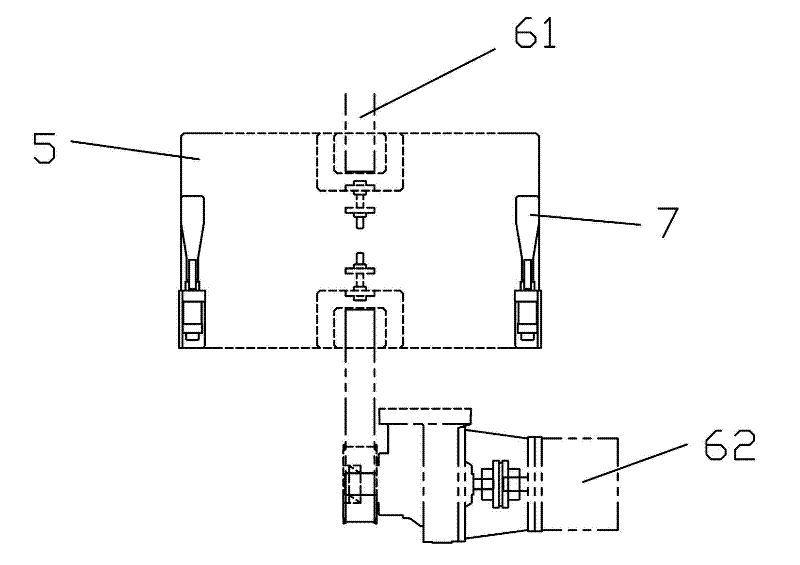

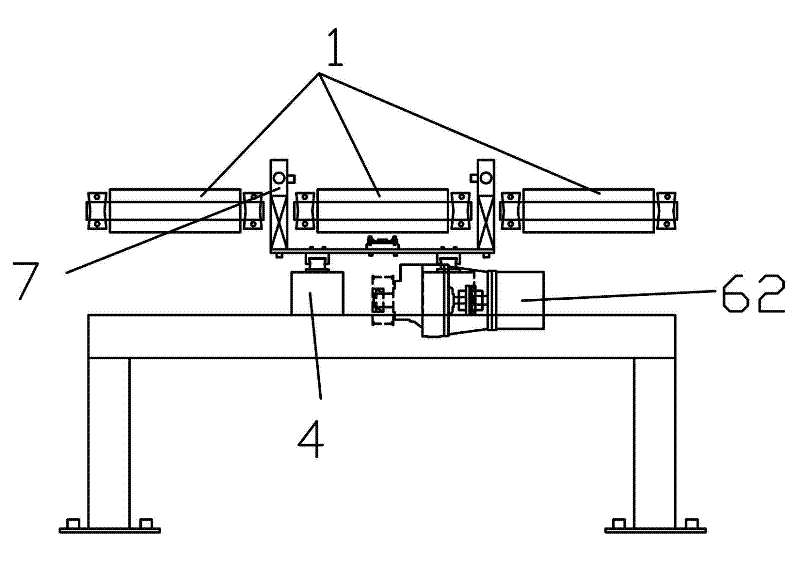

[0014] refer to Figure 1-Figure 3 , an automatic metal substrate feeding device of the present invention includes at least three sets of conveyor belts 1 distributed side by side and a first drive device 2 for controlling the synchronous movement of the conveyor belts 1 . Considering that the conveyor belt 1 is not always moving, it needs to stop according to the situation when it is working, because for better driving effect, the first driving device 2 is preferably realized by a servo motor.

[0015] The conveying surface of the conveyor belts 1 is set on the same horizontal plane, there is a gap 3 between two conveyor belts 1, and the linear guide rail 4 with the same conveying direction as the conveyor belt 1 is arranged under the conveyor belt 1, and the linear guide rail 4 is installed with a The suction device 5 sliding along the linear guide rail 4, the sliding speed when the suction device 5 slides forward is the same as the conveying speed of the conveyor belt 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com