Spooling-free yarn-dyeing bobbin

A yarn dyeing bobbin and winding-free technology, which is applied in the field of yarn dyeing bobbin, can solve the problems that the dyeing bobbin cannot be used in a large area, affects the quality of the cloth surface, and the inner layer yarn slips, etc., so as to avoid the unwinding of the inner layer Phenomenon, shorten the production cycle, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

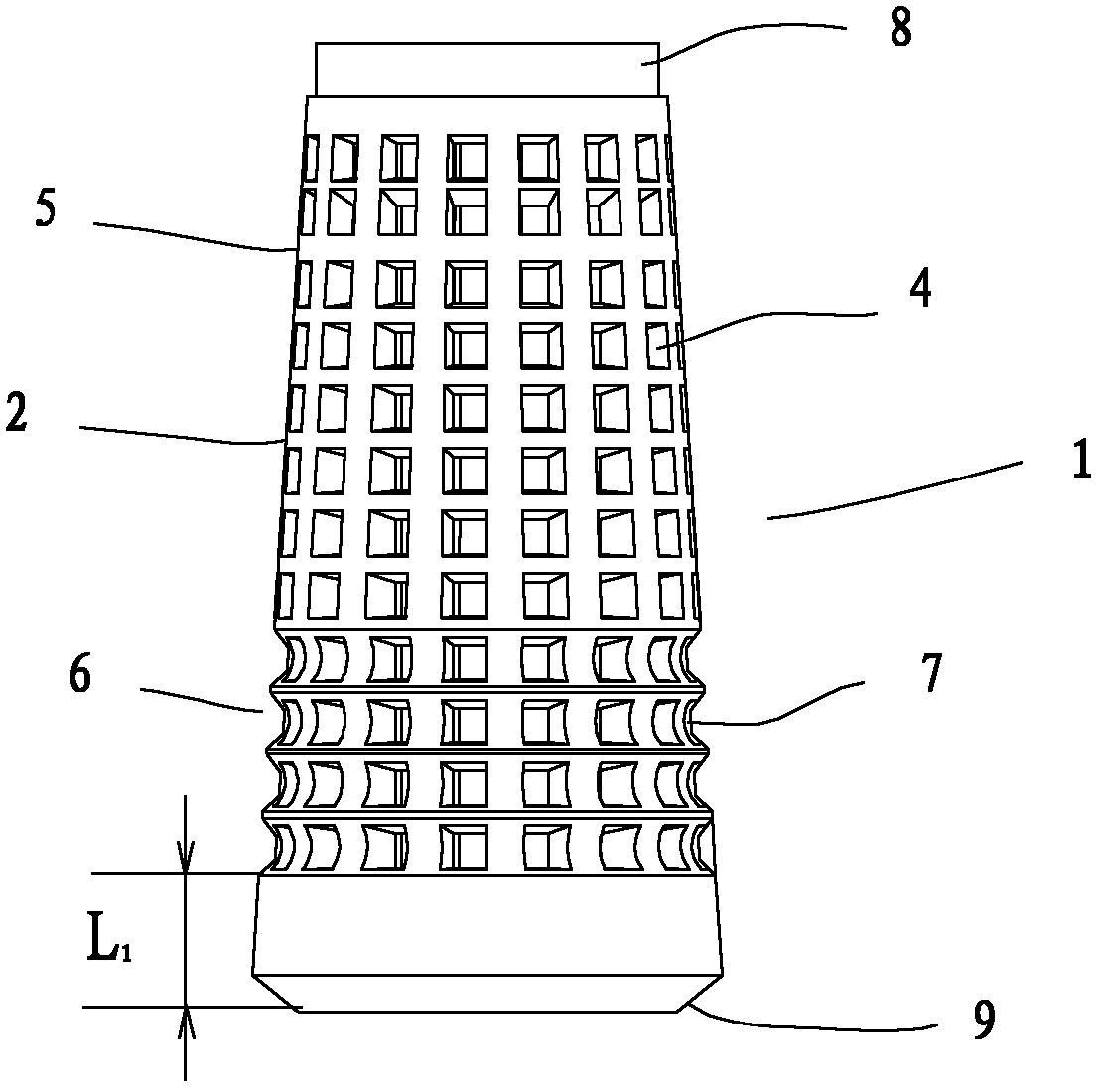

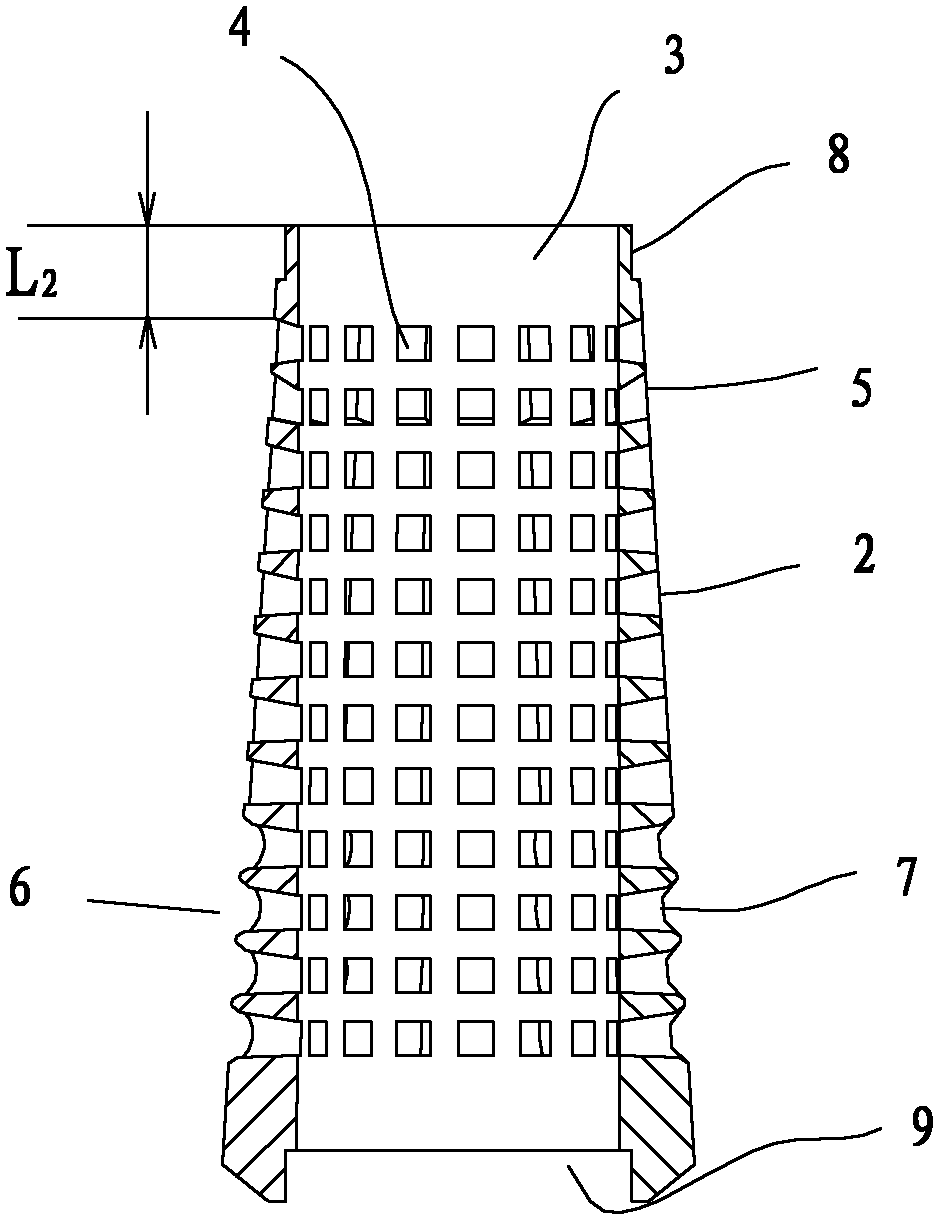

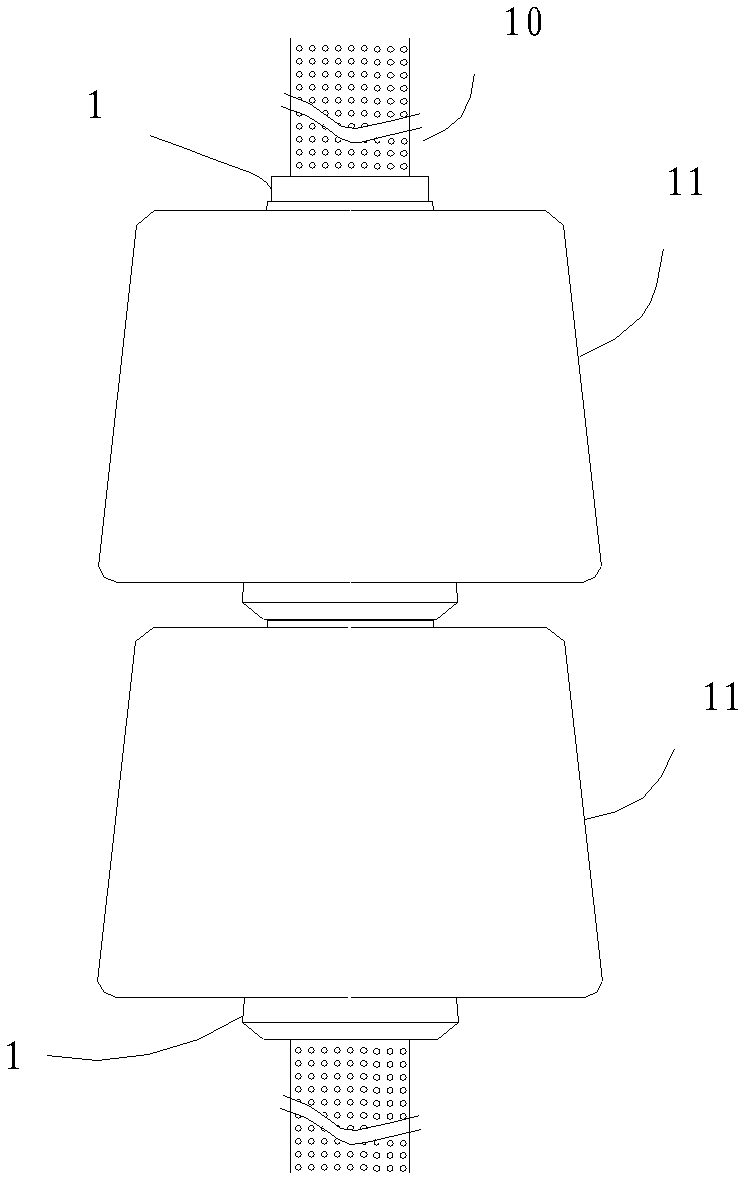

[0016] refer to Figure 1-3 , a yarn dyeing bobbin that can be used for winding-free, comprising a hollow cylinder 1 and a number of yarn dyeing holes 4 arranged on the cylinder 1, the vertical section of the inner surface 3 of the cylinder 1 is rectangular, the cylinder The outer surface 2 of 1 is composed of an upper part 5 with a trapezoidal vertical section and a lower part 6 with a trapezoidal vertical section, and the lower part 6 is provided with several annular grooves 7 . The upper end of the barrel 1 is provided with a male end 8 , and the lower end is provided with a female end 9 matching with the male end 8 . refer to image 3 , the two barrels 1 are matched by the adjacent male end 8 and the female end 9, and placed on the yarn dyeing rod 10.

[0017] The yarn dyeing holes 4 can be distributed evenly or unevenly on the cylinder body 1 , and the yarn dyeing holes 4 are also arranged in the annular groove 7 .

[0018] The lower 6 degrees account for 25%-80% of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap