Back-tilting preventive device for boom, control method of back-tilting preventive device for boom, and crawler crane

A control method and anti-tilt technology, which is applied in the field of crawler cranes and large-tonnage crawler cranes, can solve the problems of jib impact, affecting work performance, and reducing the service life of the jib, achieving good adaptability, good effect, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

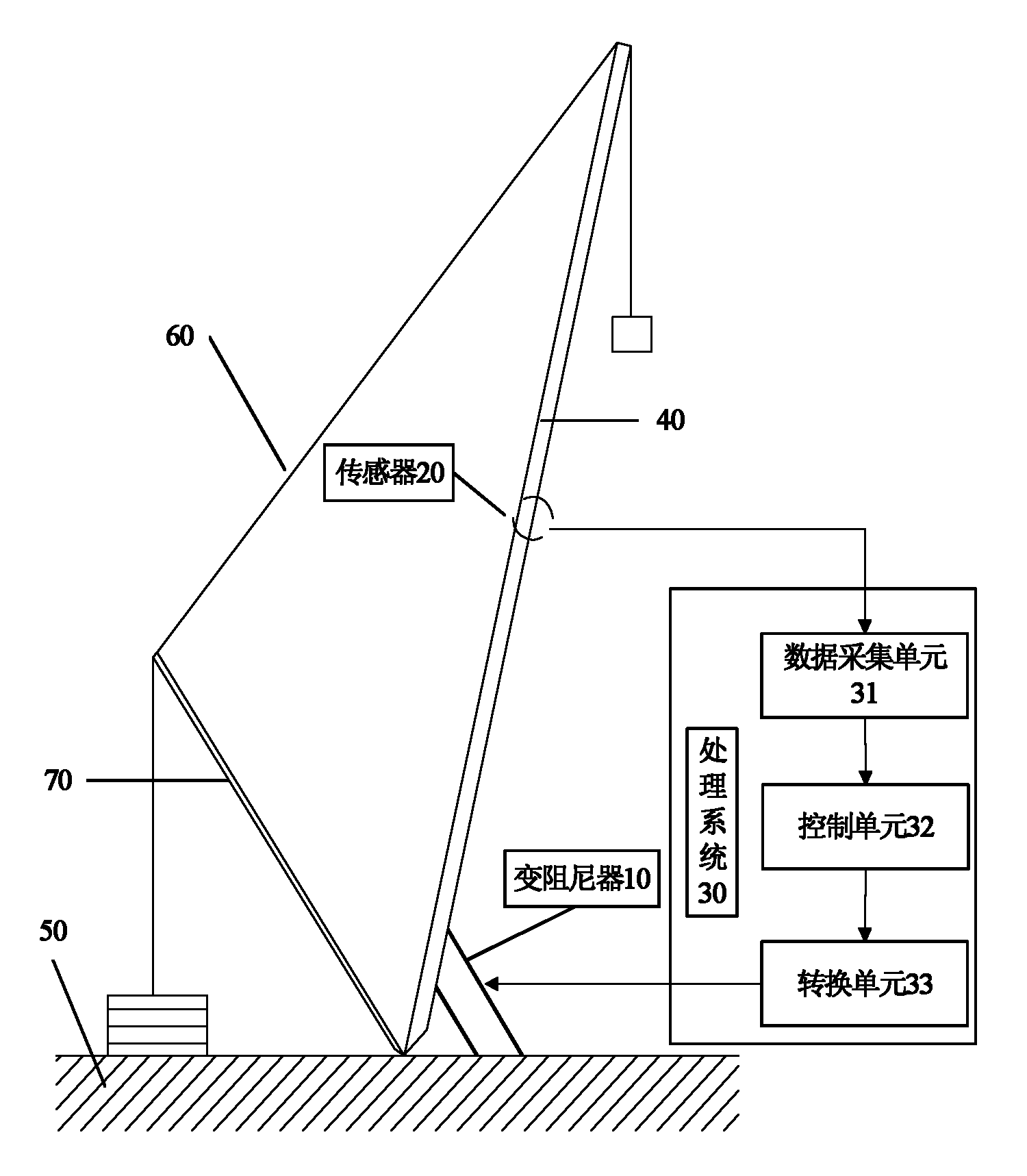

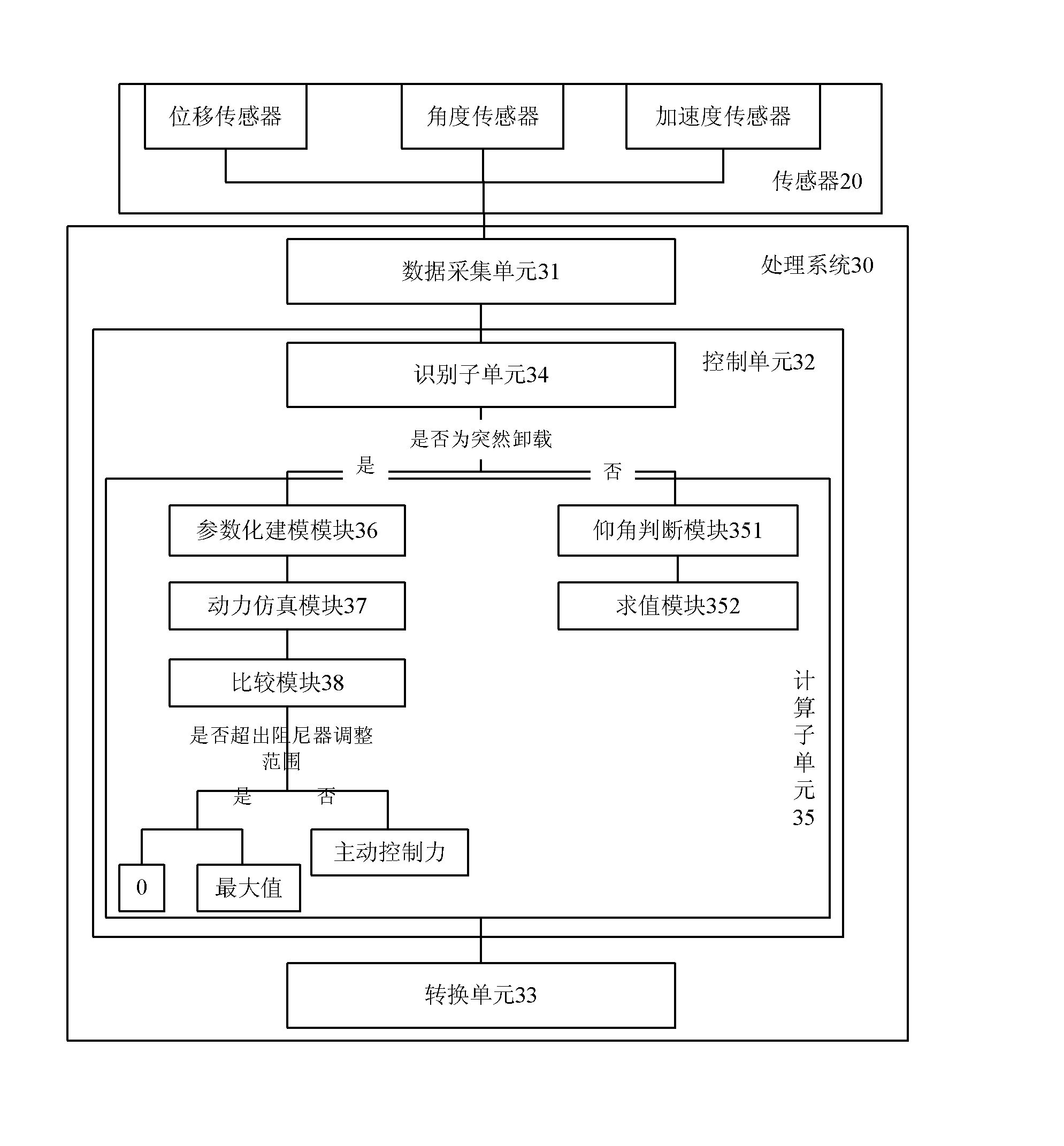

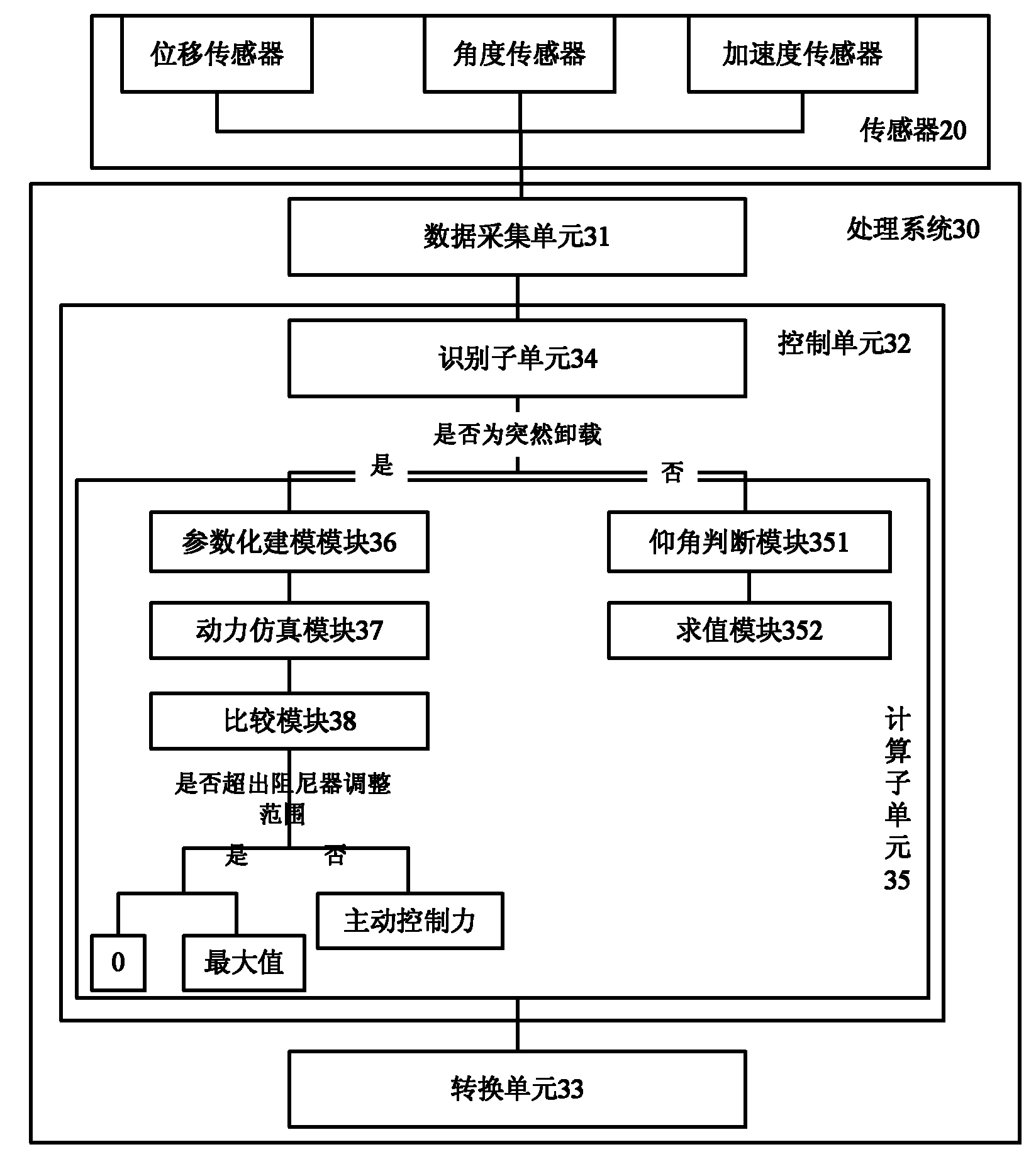

[0027] Such as figure 1 and figure 2 As shown, according to the embodiment of the present invention, the boom anti-rolling device includes a sensor 20 , a processing system 30 and a variable damper 10 . The arm frame 40 is arranged on the base, and the variable damper 10 is arranged between the arm frame 40 and the base. When the jib frame 40 is the main jib, the variable damper 10 is arranged between the main jib and the turntable 50 to support the main jib. One end of the variable damper 10 is hinged on the arm frame 40 , and the other end is hinged or rotatably arranged on the turntable 50 through a ball joint. The sensor 20 is arranged on the boom 40, including a displacement sensor, an angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com