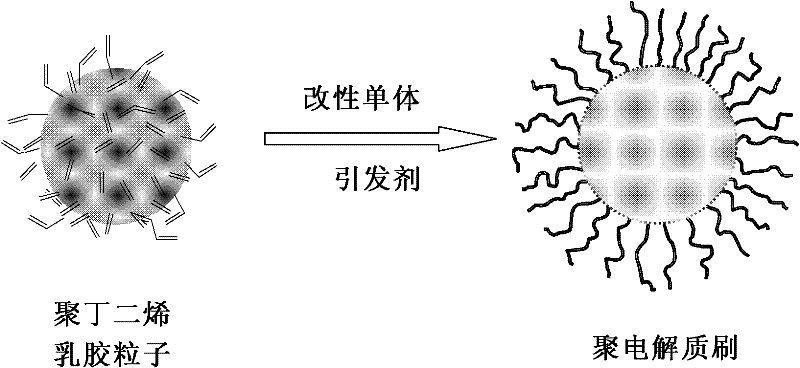

Method for preparing nano spherical polyelectrolyte brush

A polyelectrolyte brush and spherical technology, which is applied in the field of preparation of nano-spherical polyelectrolyte brushes, can solve the problems of difficult industrialization of nano-spherical polyelectrolyte brushes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

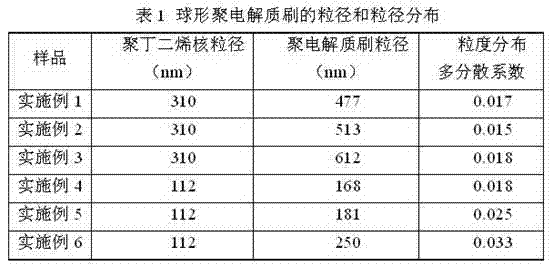

[0015] Take 300 grams of polybutadiene emulsion (the measured solid content is 2%, particle diameter is 312 nanometers), add 0.12 grams of potassium persulfate (2% of the polybutadiene emulsion solid content). Pump nitrogen 3 to 5 times, raise the temperature to 80°C, add 6 grams of acrylic acid monomer (100% of the solid content of the polybutadiene emulsion) dropwise quickly, and complete the polymerization after 0.5 hours. The average particle size of the spherical polyelectrolyte brushes was measured to be 612 nm (pH = 5) after dialysis in deionized water using a dialysis bag with a molecular weight cut-off of 14,000.

Embodiment 2

[0017] Take 300 grams of polybutadiene emulsion (the measured solid content is 2%, particle diameter is 312 nanometers), add 0.12 grams of potassium persulfate (2% of the polybutadiene emulsion solid content). Pump nitrogen 3 to 5 times, raise the temperature to 80°C, quickly drop 4.5 g of acrylic acid monomer (75% of the solid content of the polybutadiene emulsion) dropwise, and complete the polymerization after 0.5 hours. The average particle size of the spherical polyelectrolyte brushes was measured to be 513 nm (pH = 5) after dialysis in deionized water using a dialysis bag with a molecular weight cut-off of 14,000.

Embodiment 3

[0019] Take 300 grams of polybutadiene emulsion (the measured solid content is 2%, particle diameter is 312 nanometers), add 0.12 grams of potassium persulfate (2% of the polybutadiene emulsion solid content). Pump nitrogen 3 to 5 times, raise the temperature to 80°C, quickly drop 3 grams of acrylic acid monomer (50% of the solid content of the polybutadiene emulsion) dropwise, and complete the polymerization after 0.5 hours. The average particle size of the spherical polyelectrolyte brushes was measured to be 477 nm (pH = 5) after dialysis in deionized water using a dialysis bag with a molecular weight cut-off of 14,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com