PC/ABS halogen-free flame-retardant alloy with high surface impact strength and preparation method thereof

A high surface impact and alloy technology, which is applied in the field of high surface impact PC/ABS halogen-free flame retardant alloy and its preparation, can solve the problems of poor surface impact performance and achieve the effect of improving toughness and surface impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

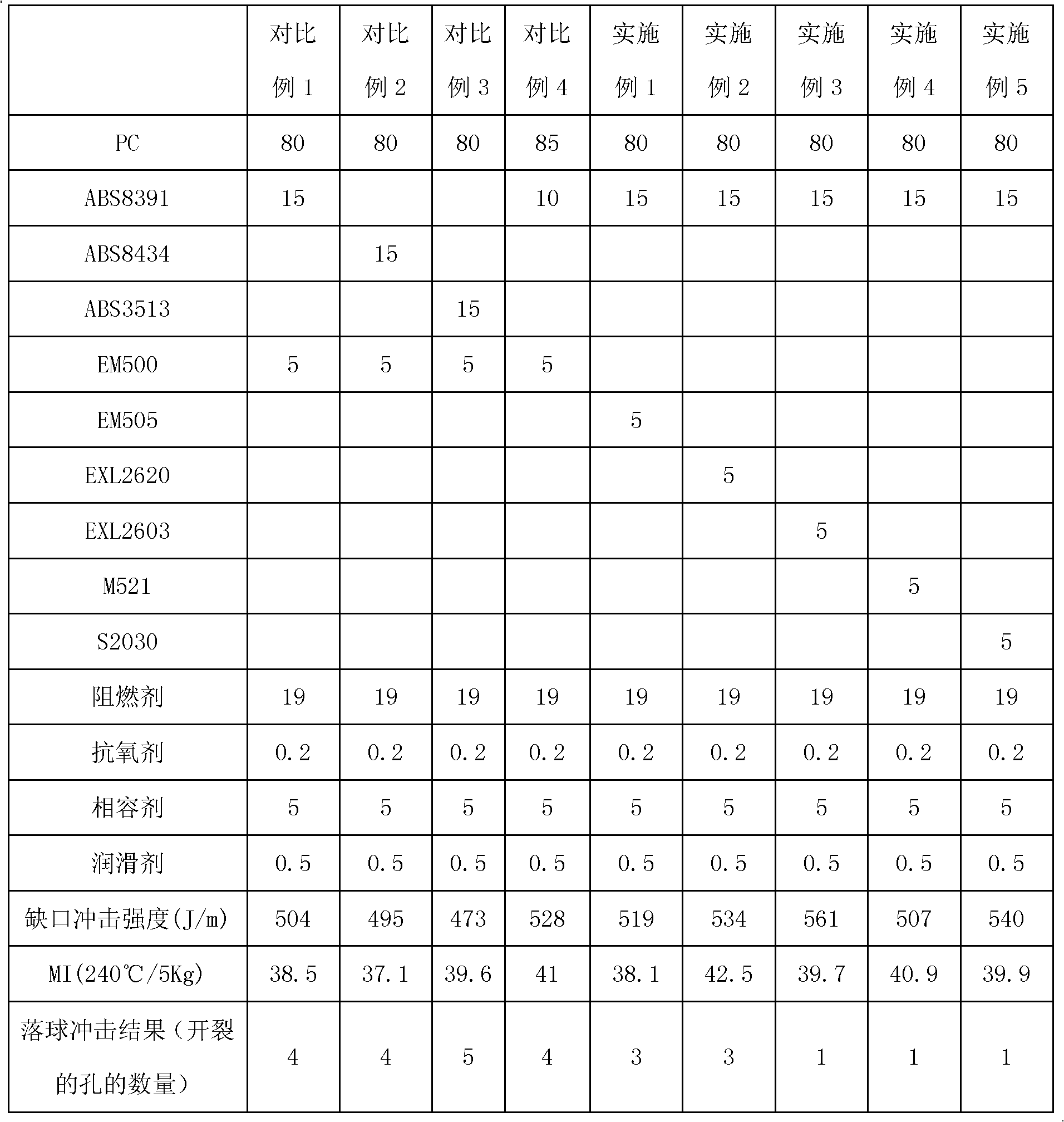

Examples

Embodiment 1

[0047] A PC / ABS halogen-free flame-retardant alloy with excellent surface impact performance and a preparation method thereof, the method comprising the following steps:

[0048] (1) Weigh each component by weight: PC-1100 is 40Kg, PC-2200 is 40Kg, ABS8391 is 15Kg, MBS: EM 505 is 5Kg, BDP is 19Kg, compatibilizer XIRAN SZ231105Kg, antioxidant 245 is 0.1Kg, antioxidant 168 is 0.1Kg, lubricant PETS is 0.5Kg, silicone powder is 0.5g.

[0049] (2) Place the other components prepared except the flame retardant in a medium-speed mixer, and mix for 20 minutes to obtain a mixed material;

[0050] (3) Put the mixed material into a twin-screw extruder, control the screw speed to 500rpm, melt and extrude, and granulate to obtain the product. The twin-screw extruder includes ten temperature control zones, the temperature of temperature control zone 1-2 is 180-260°C, the temperature of temperature control zone 3-4 is 180-260°C, the temperature of temperature control zone 5-6 is 180°C ~260...

Embodiment 2

[0052] (1) Weigh each component by weight: PC-1100 is 40Kg, PC-2200 is 40Kg, ABS8391 is 15Kg, MBS: EXL2620 is 5Kg, BDP is 19Kg, compatibilizer XIRAN SZ231105Kg, antioxidant 245 is 0.1 Kg, antioxidant 168 is 0.1Kg, lubricant PETS is 0.5Kg, silicone powder is 0.5g.

[0053] (2) Place the other components prepared except the flame retardant in a medium-speed mixer, and mix for 20 minutes to obtain a mixed material;

[0054] (3) Put the mixed material into a twin-screw extruder, control the screw speed to 500rpm, melt and extrude, and granulate to obtain the product. The twin-screw extruder includes ten temperature control zones, the temperature of temperature control zone 1-2 is 180-260°C, the temperature of temperature control zone 3-4 is 180-260°C, the temperature of temperature control zone 5-6 is 180°C ~260°C, the temperature of temperature control zone 7-8 is 180-260°C, and the temperature of temperature control zone 9-10 is 180-260°C. There are two vacuum places on the tw...

Embodiment 3

[0056] (1) Weigh each component by weight: PC-1100 is 40Kg, PC-2200 is 40Kg, ABS8391 is 15Kg, MBS: EXL2603 is 5Kg, BDP is 19Kg, compatibilizer XIRAN SZ231105Kg, antioxidant 245 is 0.1 Kg, antioxidant 168 is 0.1Kg, lubricant PETS is 0.5Kg, silicone powder is 0.5g.

[0057] (2) Place the other components prepared except the flame retardant in a medium-speed mixer, and mix for 20 minutes to obtain a mixed material;

[0058] (3) Put the mixed material into a twin-screw extruder, control the screw speed to 500rpm, melt and extrude, and granulate to obtain the product. The twin-screw extruder includes ten temperature control zones, the temperature of temperature control zone 1-2 is 180-260°C, the temperature of temperature control zone 3-4 is 180-260°C, the temperature of temperature control zone 5-6 is 180°C ~260°C, the temperature of temperature control zone 7-8 is 180-260°C, and the temperature of temperature control zone 9-10 is 180-260°C. There are two vacuum places on the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com