Preparation method of scale-like high-weather-resistance ABS material

An ABS material with high weather resistance technology, applied in the field of ABS materials, can solve the problems of poor weather resistance, reduction of ABS material quality and strength, shortening the service life of ABS materials, etc., to improve protection performance, reduce interference, and improve surface impact strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

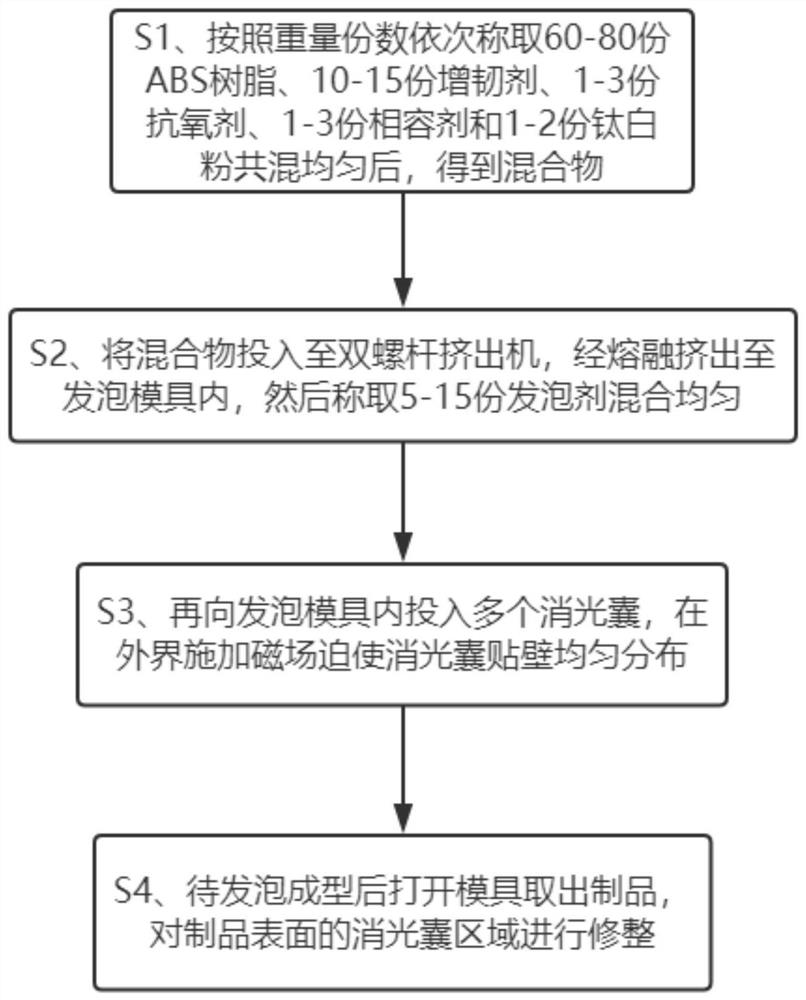

[0041] see Figure 1-2 , a preparation method of scale-like high weather resistance ABS material, comprising the following steps:

[0042] S1. Weighing 60 parts of ABS resin, 10 parts of toughening agent, 1 part of antioxidant, 1 part of compatibilizer and 1 part of titanium dioxide in sequence according to parts by weight and blending uniformly to obtain a mixture;

[0043] S2, the mixture is put into a twin-screw extruder, melted and extruded into a foaming mold, and then 5 parts of foaming agent are weighed and mixed evenly;

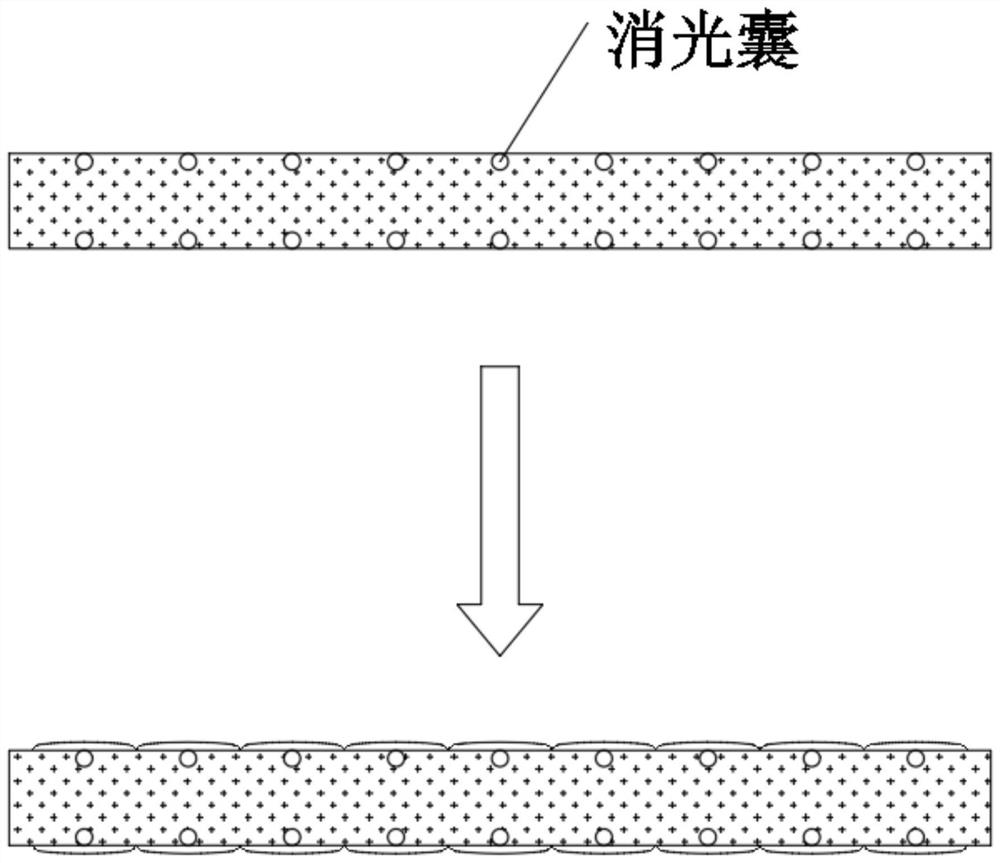

[0044] S3, put a plurality of matting capsules into the foaming mold, and apply a magnetic field to force the matting capsules to be evenly distributed on the wall;

[0045] S4. After foam molding, open the mold to take out the product, and trim the matting area on the surface of the product.

[0046] The toughening agent is at least one of ethylene-n-butyl acrylate-glycidyl ester and high rubber powder, the antioxidant is at least one of hindered p...

Embodiment 2

[0056] A preparation method of scale-like high weather resistance ABS material, comprising the following steps:

[0057] S1. Weighing 70 parts of ABS resin, 12 parts of toughening agent, 2 parts of antioxidant, 2 parts of compatibilizer and 1.5 parts of titanium dioxide in sequence according to parts by weight and blending uniformly to obtain a mixture;

[0058] S2, the mixture is put into a twin-screw extruder, melted and extruded into a foaming mold, and then 10 parts of foaming agent are weighed and mixed evenly;

[0059] S3, put a plurality of matting capsules into the foaming mold, and apply a magnetic field to force the matting capsules to be evenly distributed on the wall;

[0060] S4. After foam molding, open the mold to take out the product, and trim the matting area on the surface of the product.

[0061] In step S2, the extrusion temperature of the twin-screw extruder is 200° C., and the screw speed is 400 r / min.

[0062] The foaming agent in step S2 is obtained b...

Embodiment 3

[0066] A preparation method of scale-like high weather resistance ABS material, comprising the following steps:

[0067] S1. Weighing 80 parts of ABS resin, 15 parts of toughening agent, 3 parts of antioxidant, 3 parts of compatibilizer and 2 parts of titanium dioxide in order according to parts by weight and blending uniformly to obtain a mixture;

[0068] S2, the mixture is put into a twin-screw extruder, melted and extruded into a foaming mold, and then 15 parts of foaming agent are weighed and mixed evenly;

[0069] S3, put a plurality of matting capsules into the foaming mold, and apply a magnetic field to force the matting capsules to be evenly distributed on the wall;

[0070] S4. After foam molding, open the mold to take out the product, and trim the matting area on the surface of the product.

[0071] In step S2, the extrusion temperature of the twin-screw extruder is 220° C., and the screw speed is 500 r / min.

[0072] The foaming agent in step S2 is obtained by ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com