A method for improving interwall strength in ultra-large fused deposition 3D printing

A fused deposition and 3D printing technology, applied in the field of 3D printing, can solve the problems of increasing the surface airtightness of printed components and insufficient bonding strength between walls of ultra-large-scale 3D printed components, so as to improve surface airtightness and improve internal Improvement of compactness and surface impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

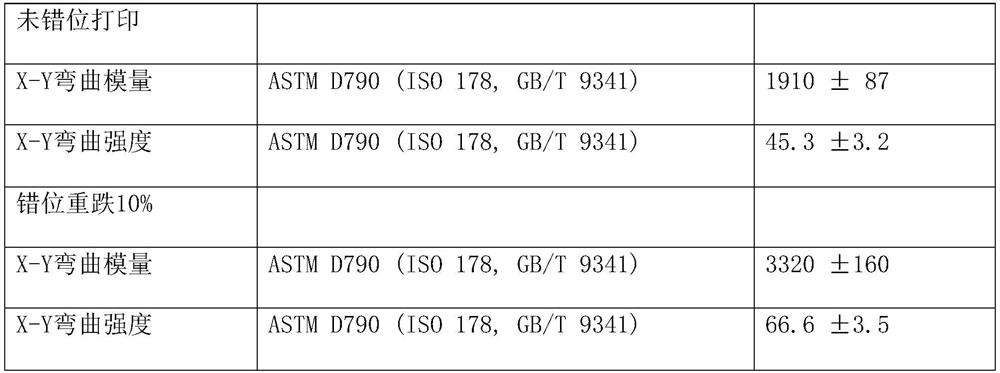

Examples

Embodiment Construction

[0040] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

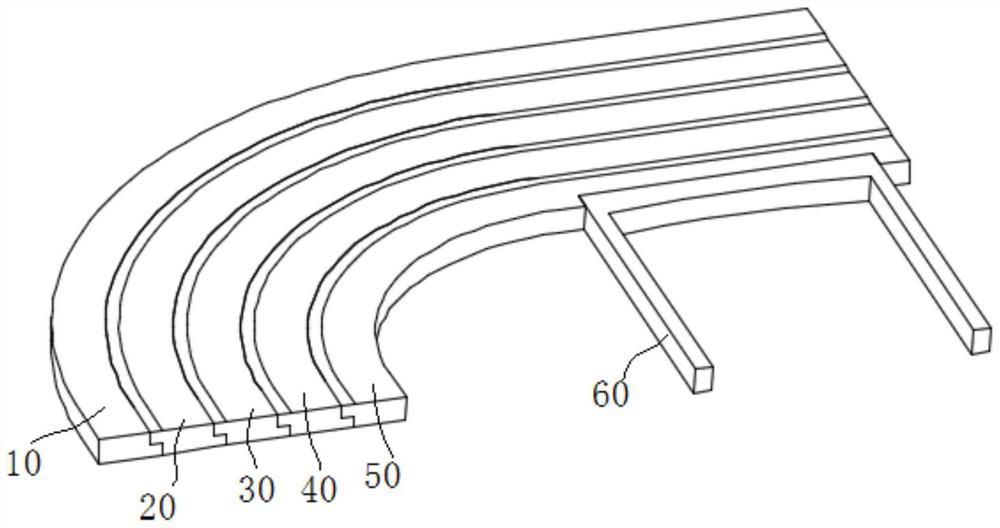

[0041] see figure 1 As shown, the present invention discloses a method for improving interwall strength by ultra-large fused deposition 3D printing, including the following steps:

[0042] (1) Input the 3D printing model of the printing component, slice the 3D printing model of the printing component according to the set layer thickness, and generate multiple sequentially stacked slice layers (printing layers), each slice layer corresponds to the printing of the current layer Component plane graphics, the plane graphics of the printed components are consistent with the cross-section of the printed components located in the slice layer; in this application, the total number of slice layers is set to N layers, and N is greater than 1, and the outermost layer of the slice is the print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com