Fixed point marking method for deformation detection of cold-rolled steel strip

A technology of cold-rolled steel strip and marking method, which is applied in the direction of measuring devices, instruments, and optical devices, which can solve the problems of difficult accurate alignment, direct corresponding analysis, and difficult detection results, and achieve the effect of avoiding differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

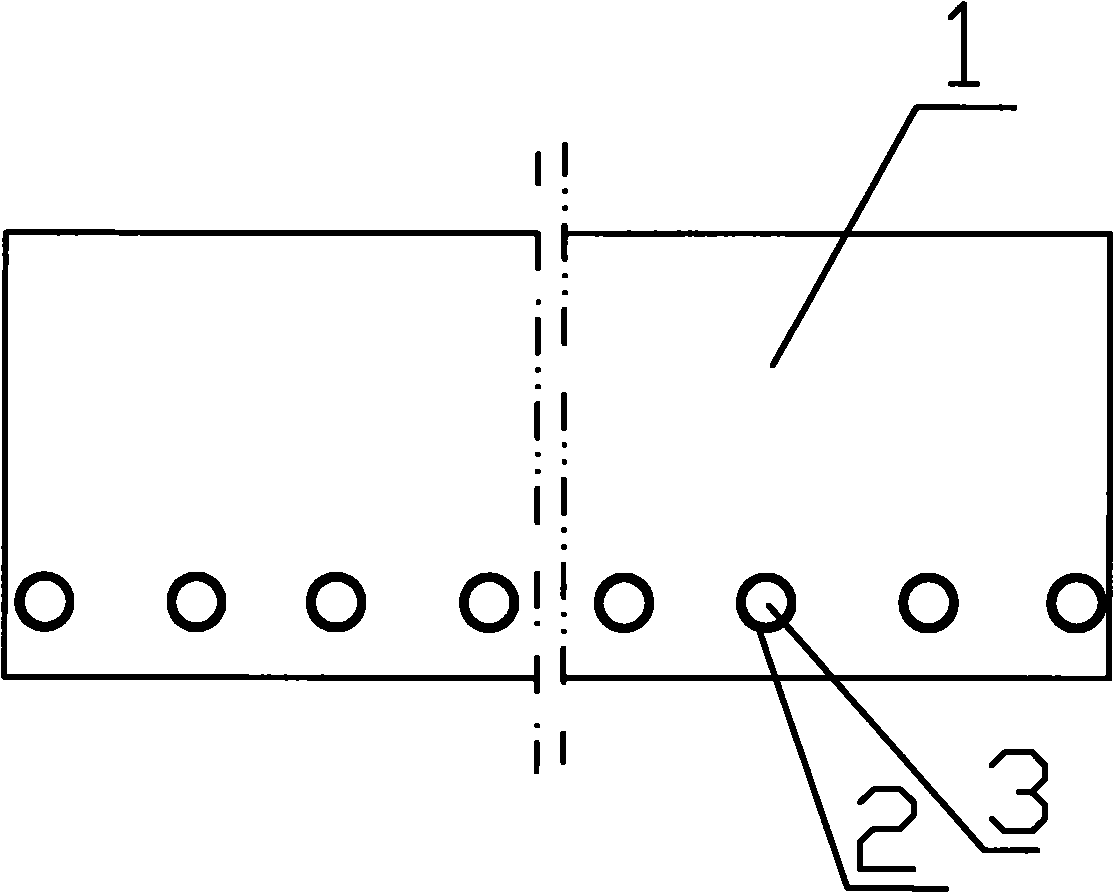

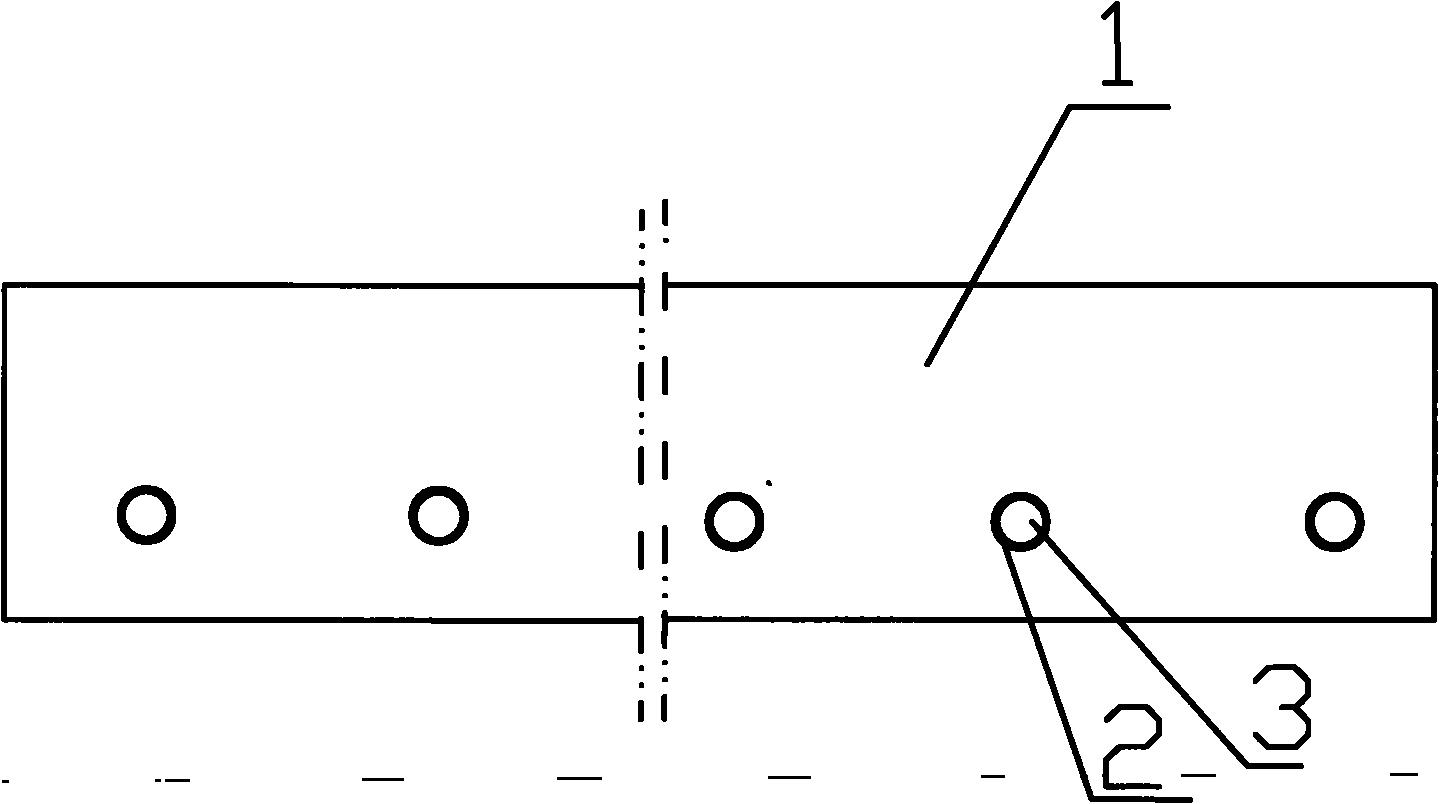

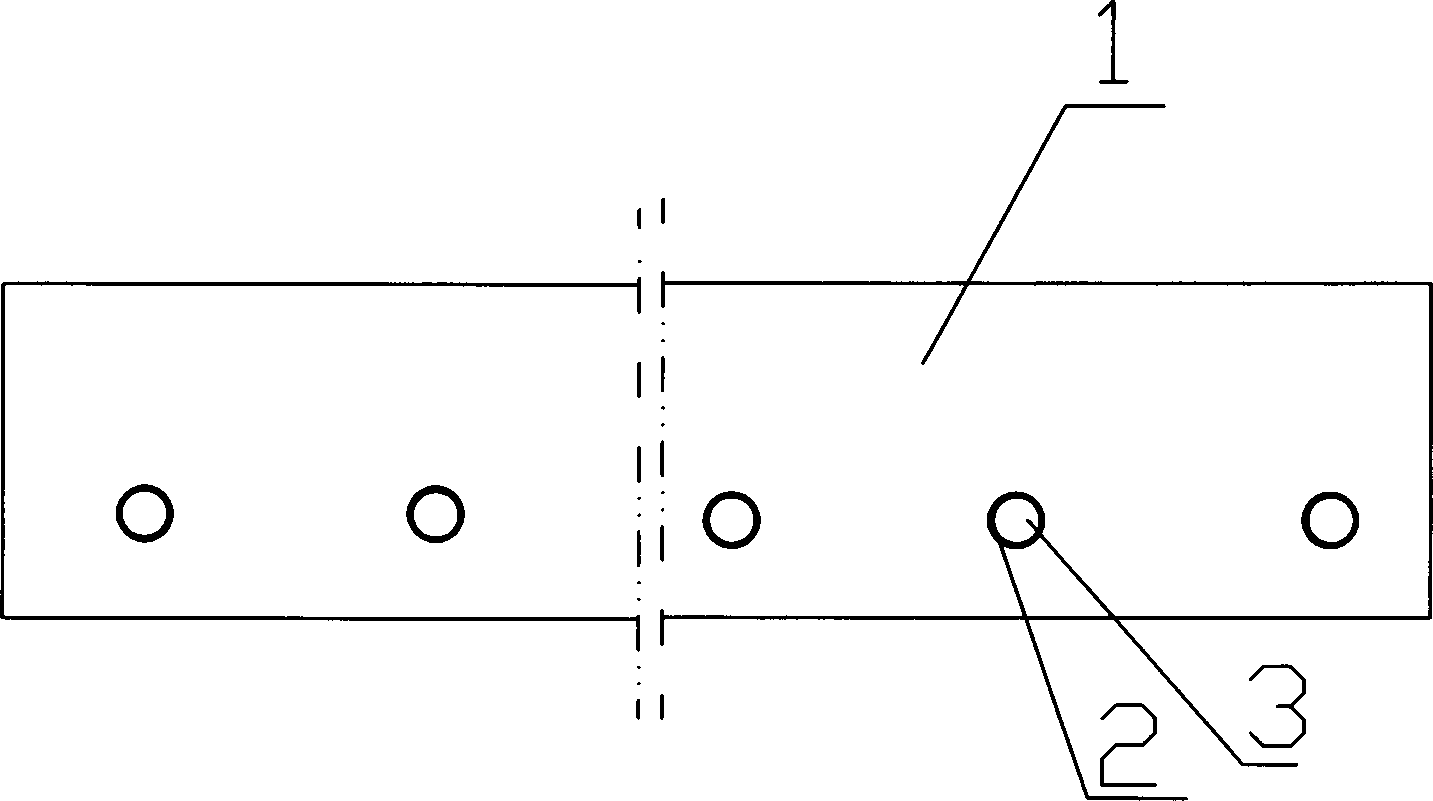

[0012] The fixed-point marking method for cold-rolled steel strip deformation detection is characterized in that: figure 1 , It is to mark a row of positioning points on the raw material of the hot-rolled steel strip 1 at the same interval, then drill through holes 2 on the positioning points, the diameter of the through holes 2 is 3mm, and finally embed copper wires in the through holes 3 is fine. The embedded copper wire 3 marks the deformation of the raw material of the hot-rolled steel strip 1 at the location during the cold rolling process. After the cold rolling is completed, see figure 2 .

[0013] As an improvement of the present invention, the copper wire 3 is an annealed copper wire, and the copper wire 3 is an interference fit with the through hole 2 to ensure that it will not fall off during the rolling process.

[0014] The distance between adjacent through holes 2 is 100 cm.

[0015] The thickness of the hot-rolled raw material is 2.0mm, the width is 750mm, and the ...

Embodiment 2

[0017] The fixed-point marking method for cold-rolled steel strip deformation detection is to first mark a row of positioning points on the raw material of hot-rolled steel strip 1 at the same interval, then drill through holes 2 on the positioning points, and finally in the through holes Just insert the copper wire 3. Punching holes 2 and rolling are the same as in Example 1. Only the diameter of the through hole 2 is 2 mm and the distance between adjacent through holes 2 is 50 cm. The thickness of the hot-rolled raw material is 2.5mm, the width is 1520mm, and the thickness of the cold-rolled steel strip is 0.3mm.

Embodiment 3

[0019] The fixed-point marking method for cold-rolled steel strip deformation detection is to first mark a row of positioning points on the raw material of hot-rolled steel strip 1 at the same interval, then drill through holes 2 on the positioning points, and finally in the through holes Just insert the copper wire 3. Punching holes 2 and rolling are the same as in Example 1. Only the diameter of the through hole 2 is 4 mm and the distance between adjacent through holes 2 is 200 cm. The thickness of the hot-rolled raw material is 3.5mm, the width is 1250mm, and the thickness of the cold-rolled steel strip is 0.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com