System and method for measuring centre position and exradius of ring by utilizing snubber rolls

A technology of the radius of the outer circle and the position of the center of the circle, which is applied in the field of metal pressure forming and can solve the problem of inaccurate diameter of the ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

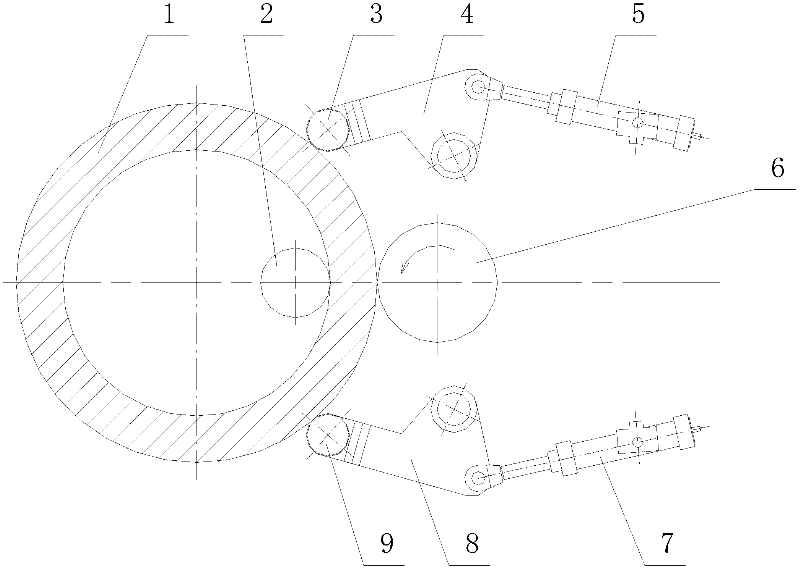

[0073] figure 2 Among them, the equipment connection diagram of the measurement system of the present invention includes: it is symmetrically provided with a holding roller I3 and a holding roller II9 on one side of the ring 1, and the two holding rollers are in contact with the outer wall of the ring 1.

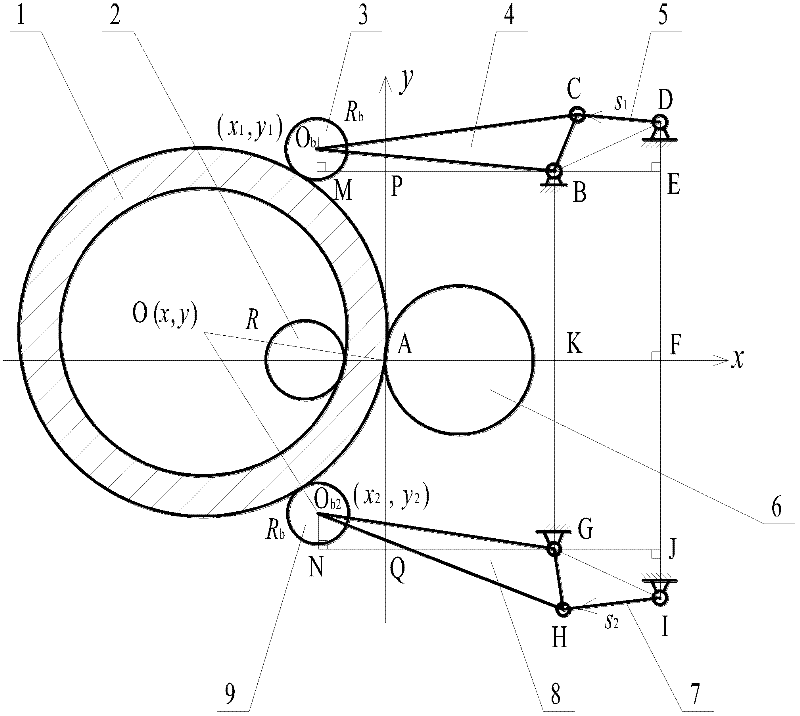

[0074] The two holding rollers are respectively connected to the corresponding oil cylinder I5 and oil cylinder II7 through their respective holding arms I4 and holding arms II8. The inner wall of the ring 1 is provided with a core roller 2 in contact, and the outer wall is in contact with the main roller 6.

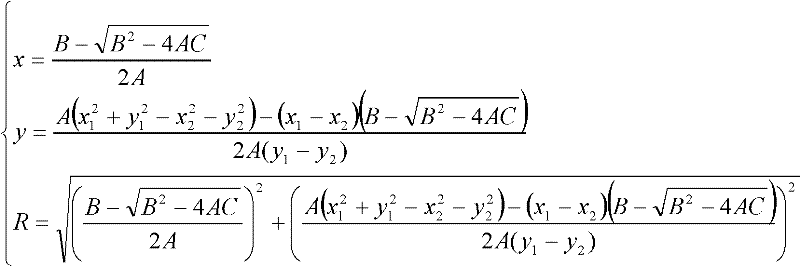

[0075] figure 1 In , the stroke s of the two cylinders at any time is measured by the built-in displacement sensors of the two cylinders 1 ,s 2 , the structural size of each component is a fixed value, the calculation diagram is as follows fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com