Detection method of turbine collision and abrasion faults

A fault detection and steam turbine technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as lack of vibration signals, unit operation not being noticed and valued by operators, difficult to touch and grind vibration signal analysis and research, etc. , to achieve the effect of improving the accuracy, suppressing the influence of measurement noise, and suppressing the influence of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention provides a method for detecting rubbing faults of steam turbines. The present invention will be further described below with reference to the drawings and specific embodiments.

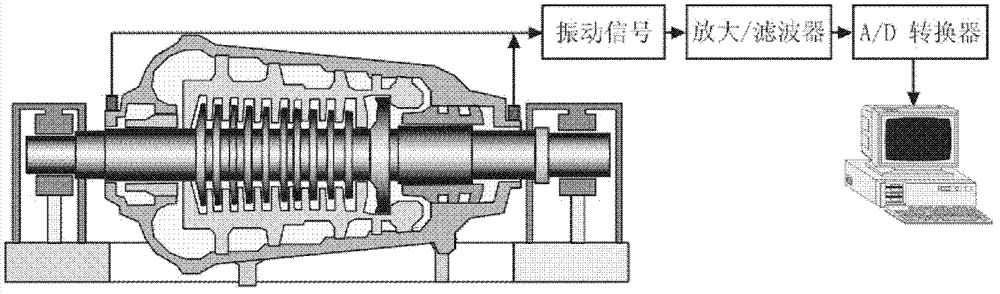

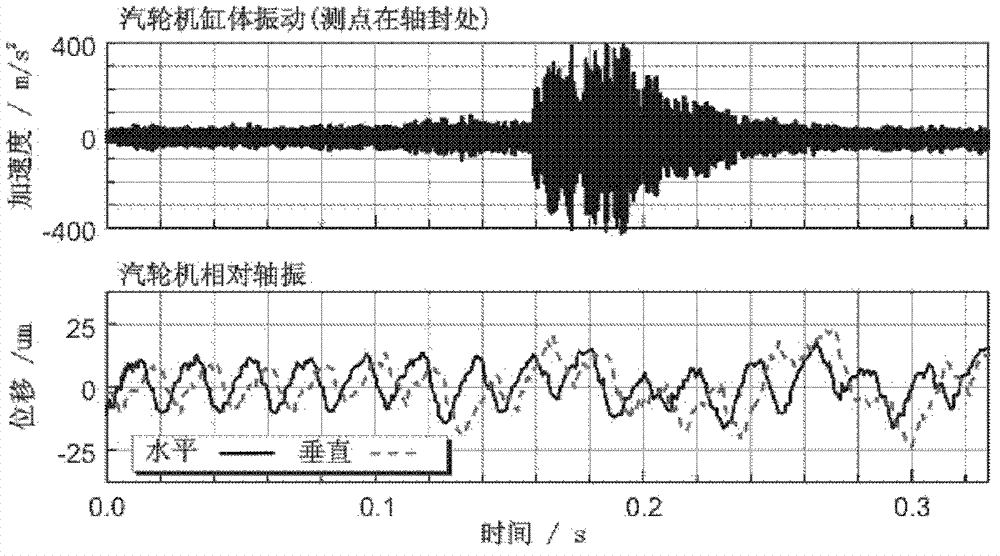

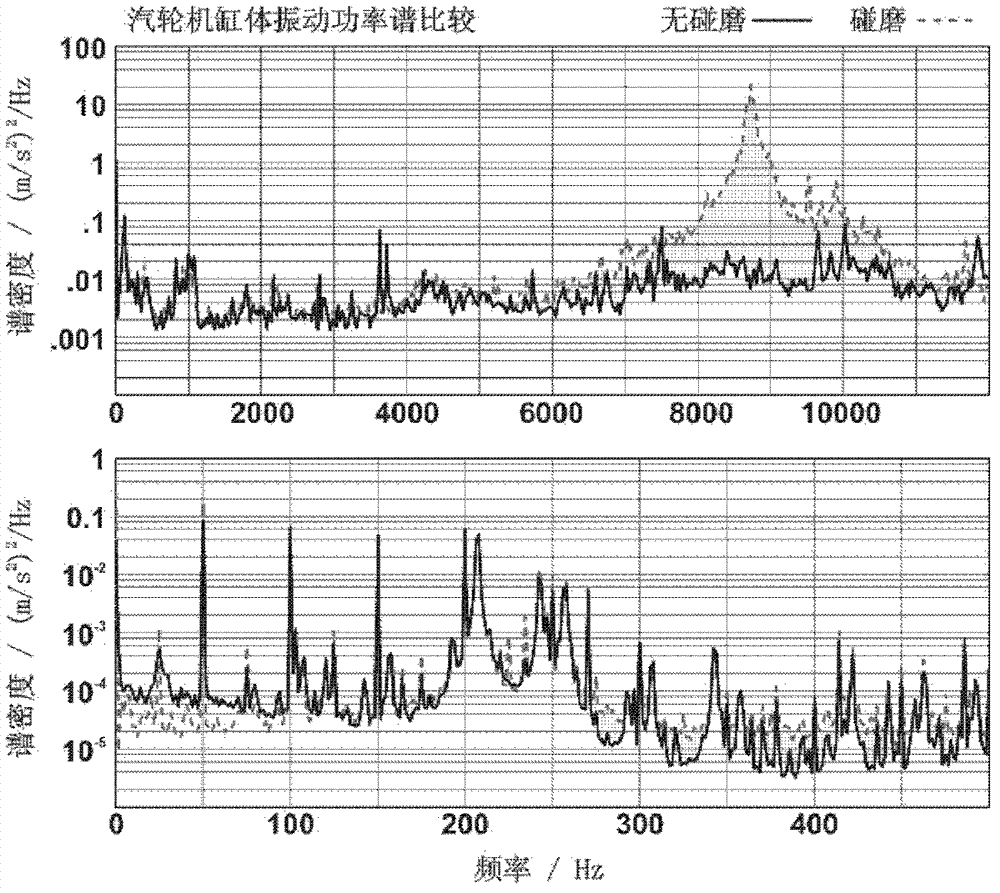

[0032] The principle of the present invention is that the impact friction occurring at a certain part of the steam turbine produces an instantaneous impact on the structure of the cylinder block, causing the structural vibration of the impact friction part. This vibration propagates in the cylinder block in the form of solid-borne sound, and passes through the axial ends of the cylinder block The piezoelectric acceleration sensor installed in the location can pick up the transmitted impact vibration signal, and continuously collect the cylinder structure vibration signal with a sampling frequency higher than the main natural frequency of the cylinder block. On this basis, through the analysis and extraction of the signal characteristics, the count information of the occurrence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com