Temperature cycling test device for OPPC (optical fiber composite phase conductor) connector box and test method

An optical fiber composite phase line and temperature cycle technology, which is applied in the direction of using optical devices to transmit sensing components, measuring devices, and testing optical performance, etc., can solve the problem of no application examples of optical fiber composite phase lines, and no correlation between the development of OPPC splice boxes and performance testing. Research and other issues, to achieve the effect of flexible and controllable temperature range, intuitive and clear test results, and convenient test analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with example the present invention is described in detail.

[0039] The purpose of the present invention is to solve the problems existing in the OPPC engineering application, and proposes a temperature cycle test device for an optical fiber composite phase line splice box, which can simulate the temperature of the splice box in the OPPC operating circuit in the laboratory simulation test at extremely low temperature and extremely high temperature Performance changes under conditions.

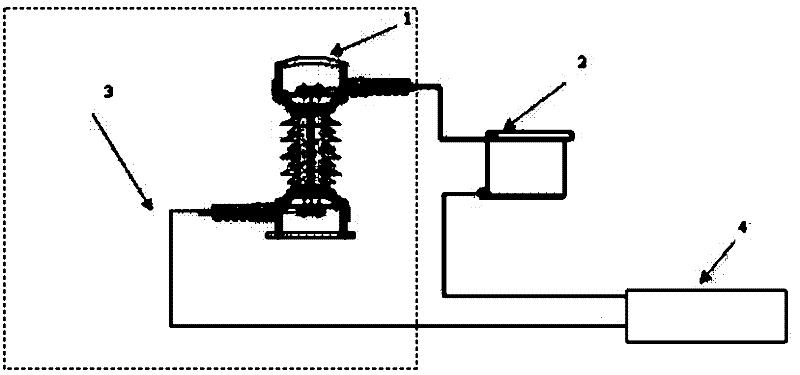

[0040] The temperature cycle test device for optical fiber composite phase line splice box is composed of OPPC splice box 1 itself, high and low temperature test box 3, auxiliary extension optical cable 2 and optical fiber attenuation tester (or optical time domain reflectometer) 4, to carry out OPPC splice box temperature cycle test The simulation diagram is attached figure 1 .

[0041] The temperature cycle test method includes the placement of optical fiber splici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com