Optical sensor capable of detecting granularity and shape feature of particles in real time

An optical sensor and real-time detection technology, which is applied in the field of optical sensors, can solve the problems of low instrument repeatability, shape detection, and limited precision, and achieve the effects of reducing residue and pollution, reducing stray light generation, and increasing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

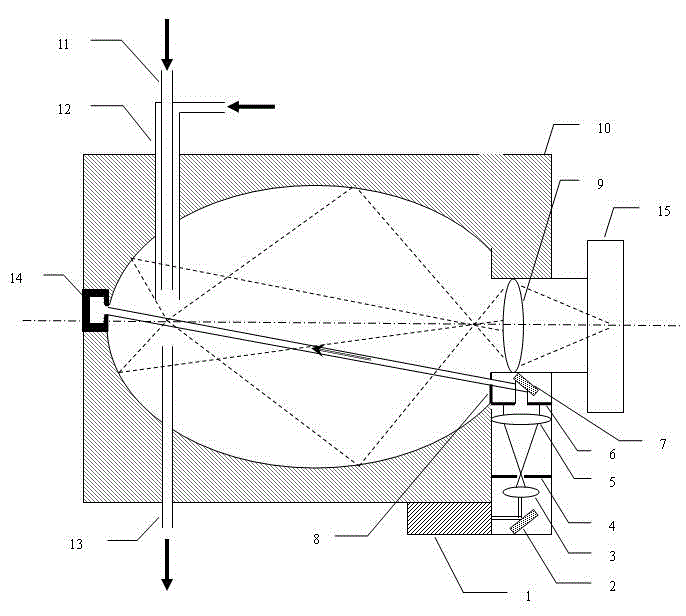

[0013] see figure 1 , due to the small size of the semiconductor laser 1, it can be fixed on the outer frame of the rotationally symmetrical elliptical cavity mirror 10, the light beam emitted by it is incident on the lens 3 after passing through the reflector 2, and forms a beam expansion, and the aperture 4 plays the role of eliminating impurities. The lens 5 makes the incident light into a parallel beam, the aperture 6 reduces the cross-sectional area of the beam, and makes the intensity uniform everywhere on the beam cross-section, and the reflector 7 makes the beam accurately enter the photosensitive area along the direction of a small angle with the long axis of the elliptical cavity mirror, The beam cross-section has the same dimension as the gas inlet and outlet channels, with a diameter of 2 mm. The aperture 8 prevents stray light from entering the cavity. The entire beam generating and incident system is compact in structure. The incident light beam and the sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com