Cross section measurement method for fiber volume fraction of steel fiber concrete

A technology of steel fiber reinforced concrete and fiber volume, applied in the direction of material inspection products, etc., can solve the problems of unsuitable concrete volume ratio measurement on pouring site, inability to measure concrete steel fiber volume ratio, large test water consumption, etc., to achieve flexible testing and testing. The effect of low cost and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Steel fiber concrete for a certain pavement uses pier-shaped steel fibers with a length of 50mm, a diameter of 0.62mm, an aspect ratio of 80, and a tensile strength of 1000MPa. Preliminary design mix ratio (Kg / m 3 ) is cement: sand: gravel: steel fiber: admixture = 380: 894: 968: 20: 4.5, the water-cement ratio is 0.36, and the steel fiber volume ratio is 0.25%.

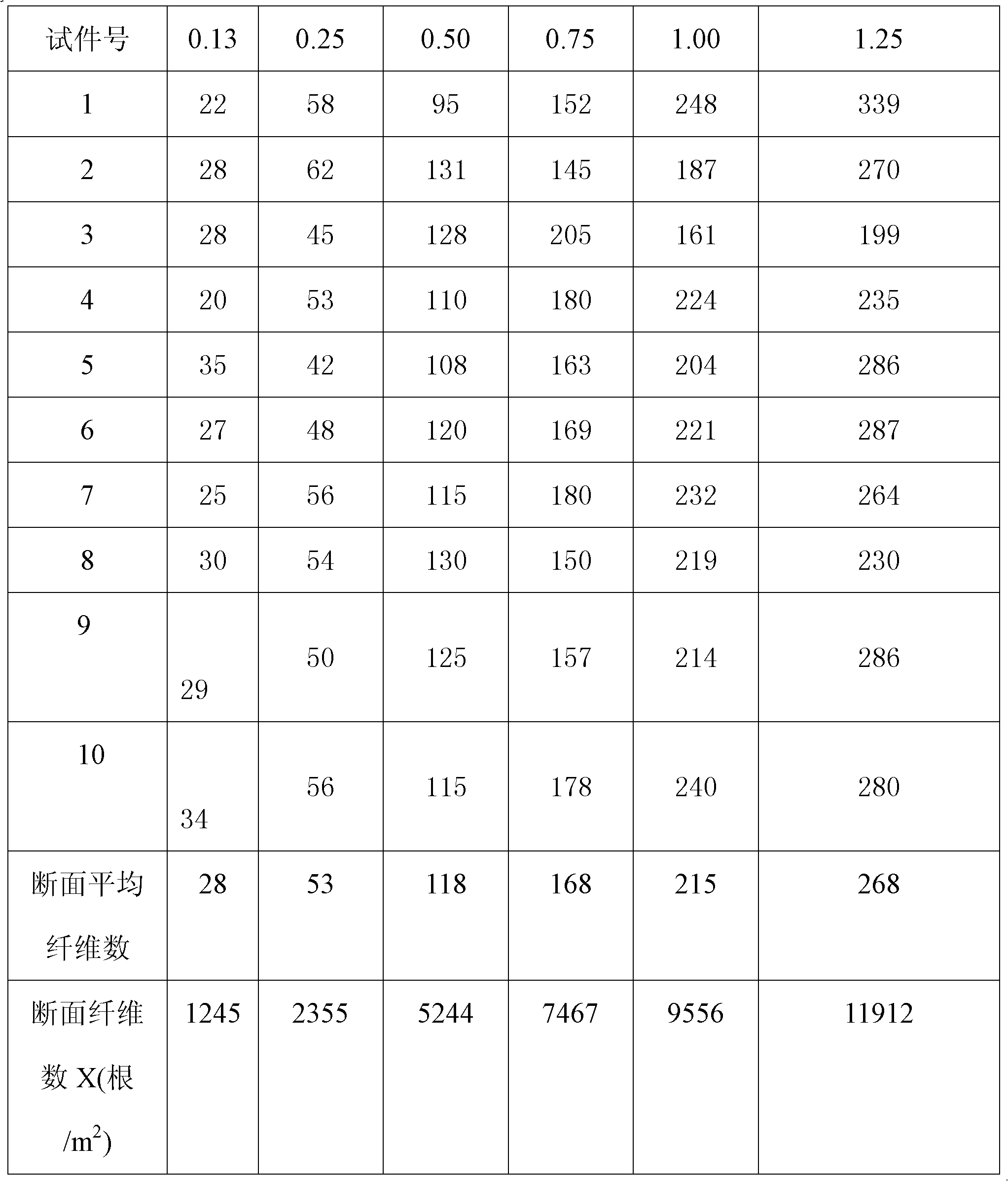

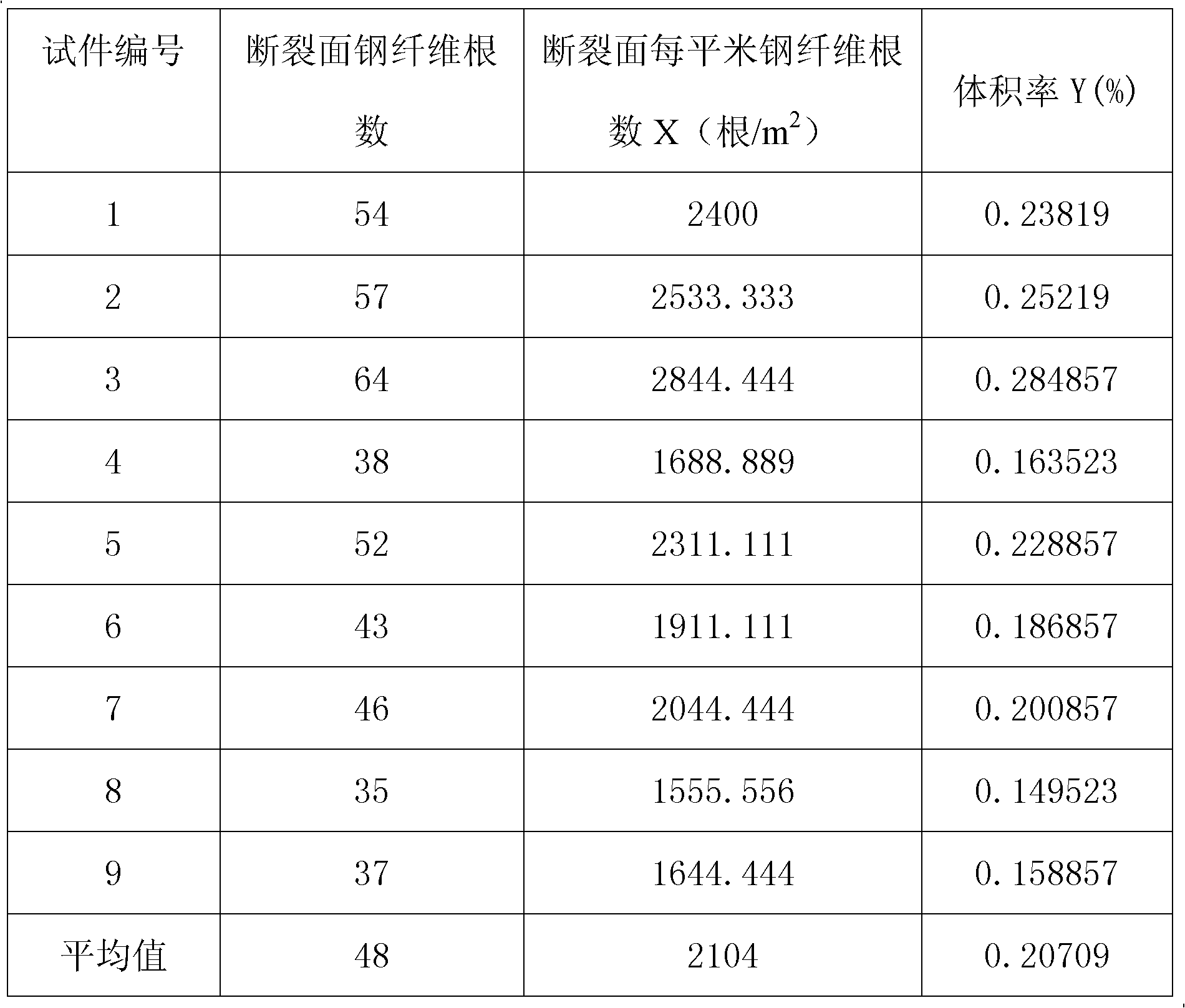

[0020] The volume ratios used in the regression analysis are 0.13%, 0.25% (design value), 0.5%, 0.75%, 1.0%, 1.25%, and the concrete mix proportions of different volume ratios in the test are based on the standard mix ratio and are based on the steel fiber volume ratio. Adjust sand rate and water usage. The test process and results of the cross-section method are as follows:

[0021] 1) Prepare concrete by adding steel fibers with different volume ratios as shown in Table 1, and form cube specimens. 10 specimens are molded for each volume ratio. After 7 days of curing, the splitting test is carried out. tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com