Method for burying and plugging holes on HDI (high-density interconnection) circuit boards

A circuit board and buried hole technology, applied in the field of circuit board manufacturing, can solve problems such as affecting PCB performance, and achieve the effects of improving efficiency, increasing surface roughness, and increasing bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] The manual laminating machine and the screen printing machine described in this embodiment are all conventional equipment, and the screen plate used by the screen printing machine is an aluminum screen plate.

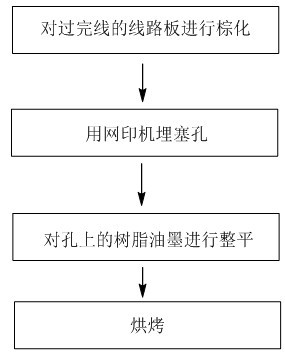

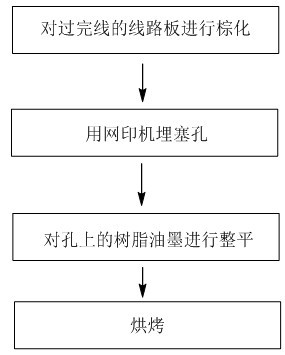

[0045] A method of plugging holes on a circuit board, comprising:

[0046] ①. The step of browning and pressing the HDI circuit board that has passed the line;

[0047] ②, the step of using the screen printing machine to bury the hole;

[0048] ③. The step of leveling the resin ink on the hole;

[0049] ④, the step of baking.

[0050] Among them, step ① can be operated according to the existing technology, and will not be described here. Step ② includes:

[0051] 1. Confirm whether the magnification of the aluminum stencil is consistent with that of the circuit board, and check whether the aluminum stencil meets the requirements (for example, whether there are burrs, pollutants, hole plugs, etc. on the surface of the aluminum stencil);

[0052] 2. Flatly set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com