Method for assembling barrel body and grinding roller of horizontal roller mill

A technology of horizontal roller mill and installation method, which is applied in the field of roller installation and cylinder body, which can solve the problems of non-compliance of temporary auxiliary platform size, no installation plan, and stability cannot be guaranteed, so as to ensure the position of the axis of the equipment and The effect of levelness, easy operation and stability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In the installation and construction of the barrel and grinding roller of the 3800mm horizontal roller mill of the steel slag powder production line:

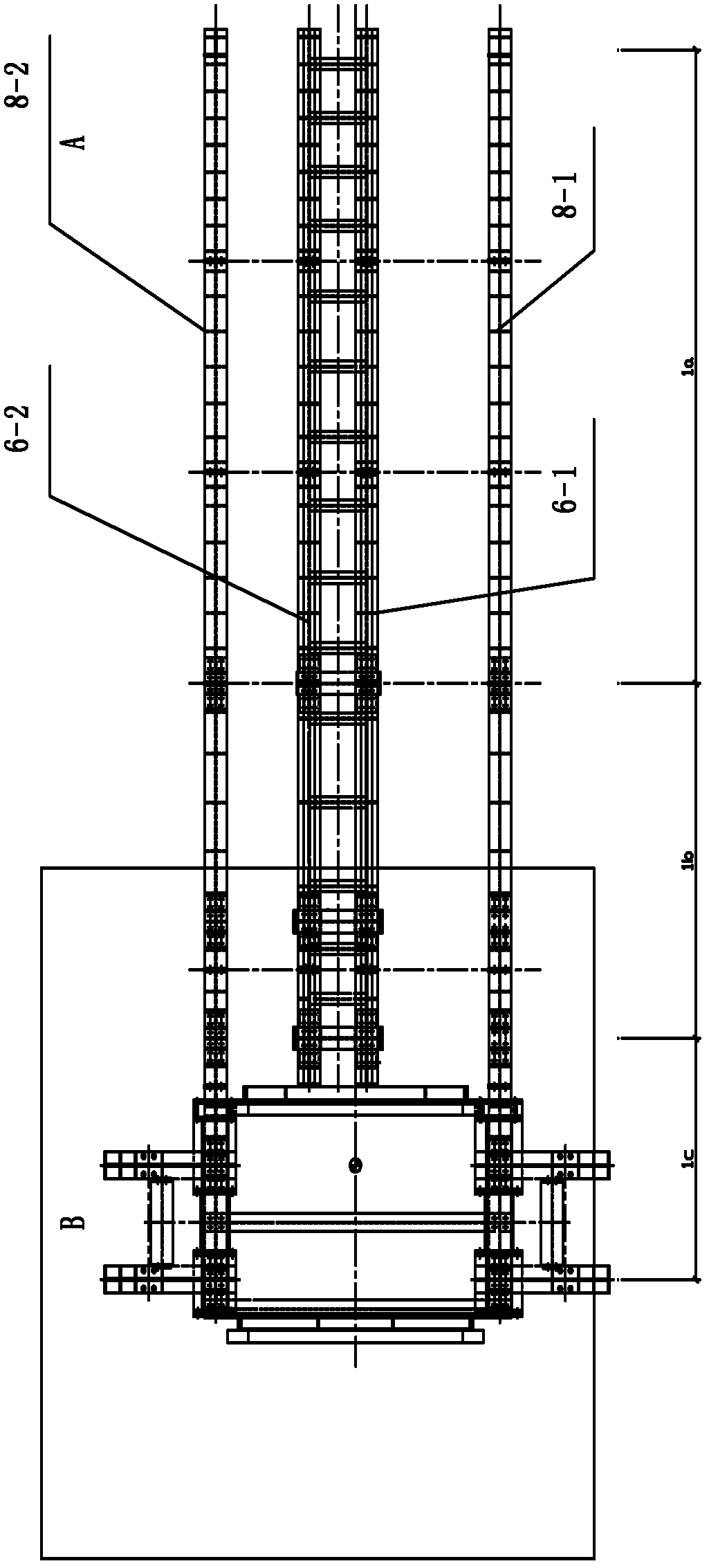

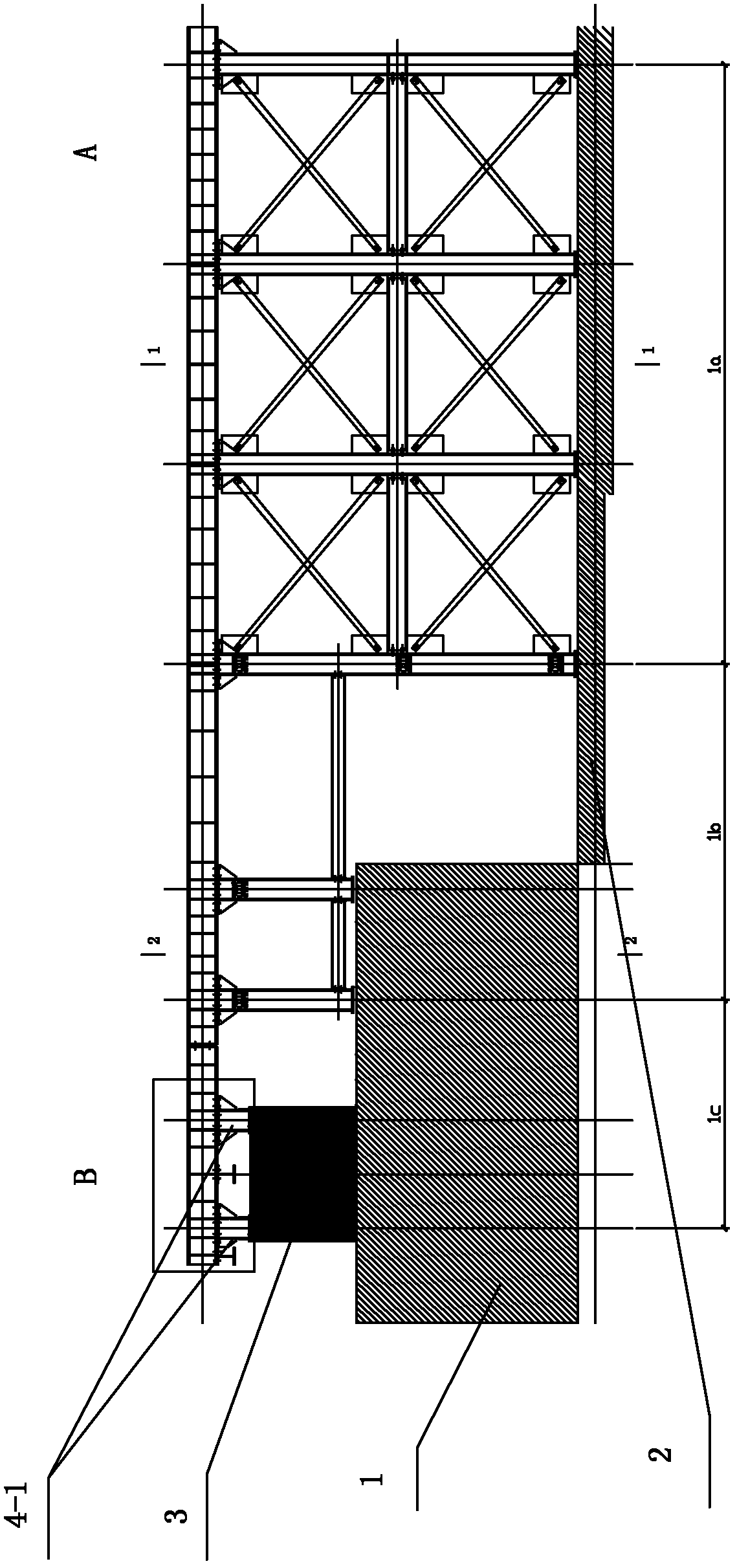

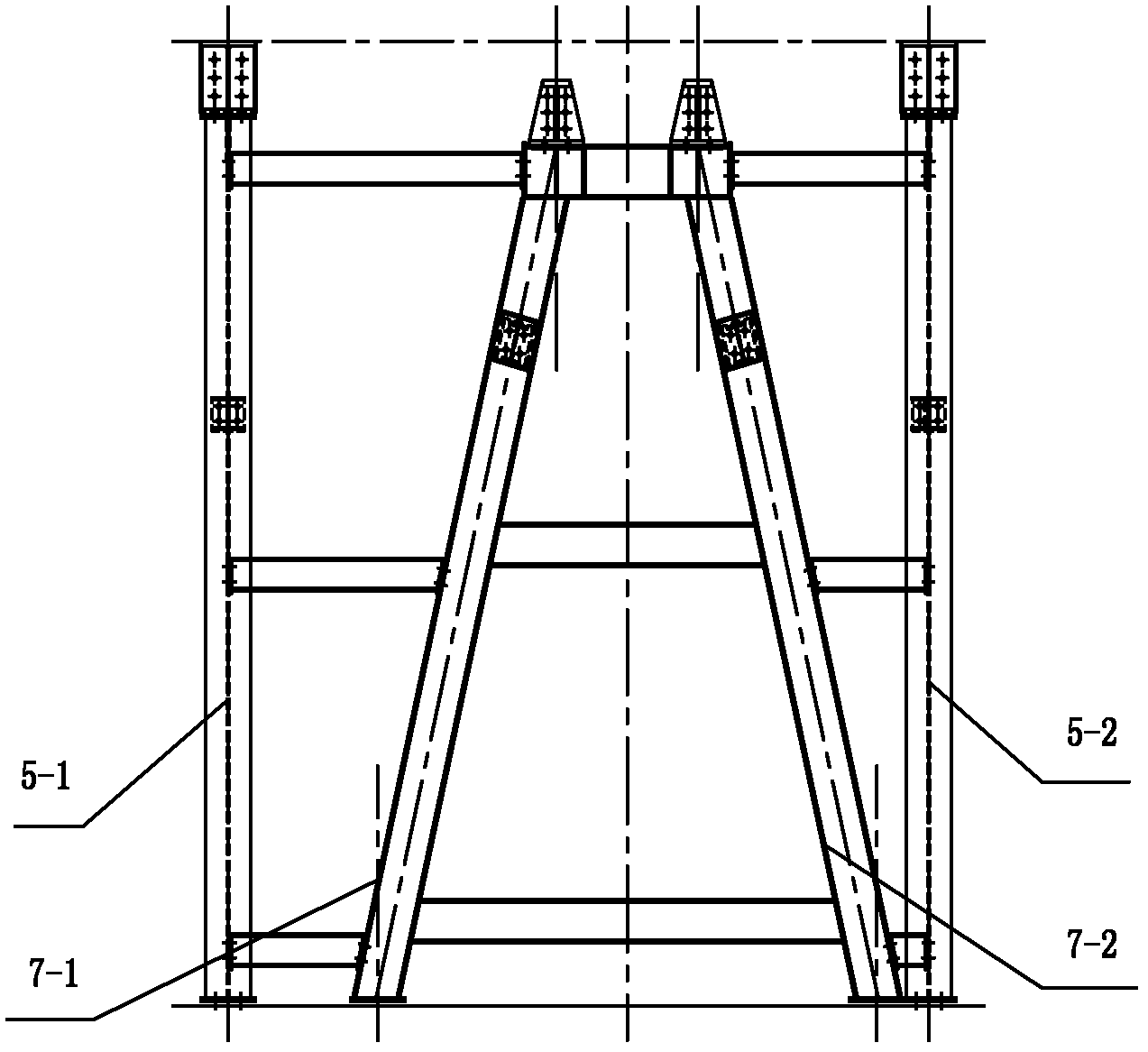

[0028](a) install the auxiliary platform, the installation process of the described auxiliary platform is as follows: (1) build the foundation, the described foundation is a ladder-shaped foundation formed by the upper step 1 and the lower step 2; The equipment base 3 is installed on the step 1, and at least two left and right bracket pillars 4-1, 4-2 are respectively installed on the left and right sides of the top surface of the equipment base. A plurality of left and right pillars 5-1, 5-2 are respectively installed at intervals on the left and right sides of the top surface, and the left side of the full-length setting is installed on the at least two left bracket pillars and the plurality of left pillars. Side steel beams 8-1, on the at least two right bracket pillars and a plurality of right pillars, a right side s...

Embodiment 2

[0031] In the installation and construction of the barrel and grinding roller of the 3800mm horizontal roller mill of the steel slag powder production line:

[0032] (a) install the auxiliary platform, the installation process of the described auxiliary platform is as follows: (1) build the foundation, the described foundation is a ladder-shaped foundation formed by the upper step 1 and the lower step 2; The equipment base 3 is installed on the step 1, and at least two left and right bracket pillars 4-1, 4-2 are respectively installed on the left and right sides of the top surface of the equipment base. A plurality of left and right pillars 5-1, 5-2 are respectively installed at intervals on the left and right sides of the top surface, and the left side of the full-length setting is installed on the at least two left bracket pillars and the plurality of left pillars. Side steel beams 8-1, on the at least two right bracket pillars and a plurality of right pillars, a right side ...

Embodiment 3

[0035] In the installation and construction of the barrel and grinding roller of the 3800mm horizontal roller mill of the steel slag powder production line:

[0036] (a) install the auxiliary platform, the installation process of the described auxiliary platform is as follows: (1) build the foundation, the described foundation is a ladder-shaped foundation formed by the upper step 1 and the lower step 2; The equipment base 3 is installed on the step 1, and at least two left and right bracket pillars 4-1, 4-2 are respectively installed on the left and right sides of the top surface of the equipment base. A plurality of left and right pillars 5-1, 5-2 are respectively installed at intervals on the left and right sides of the top surface, and the left side of the full-length setting is installed on the at least two left bracket pillars and the plurality of left pillars. Side steel beams 8-1, on the at least two right bracket pillars and a plurality of right pillars, a right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com