Dust removal device and method for manufacturing same

A technology of a dust removal device and a manufacturing method, which are applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve the problems of difficulty in controlling the ejection amount and can only be erected and ejected, and achieve a simple and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0029] The dust removal device of the present invention can be used for blowing the dust on the object, especially for blowing the dust in the narrow gaps and holes of the object.

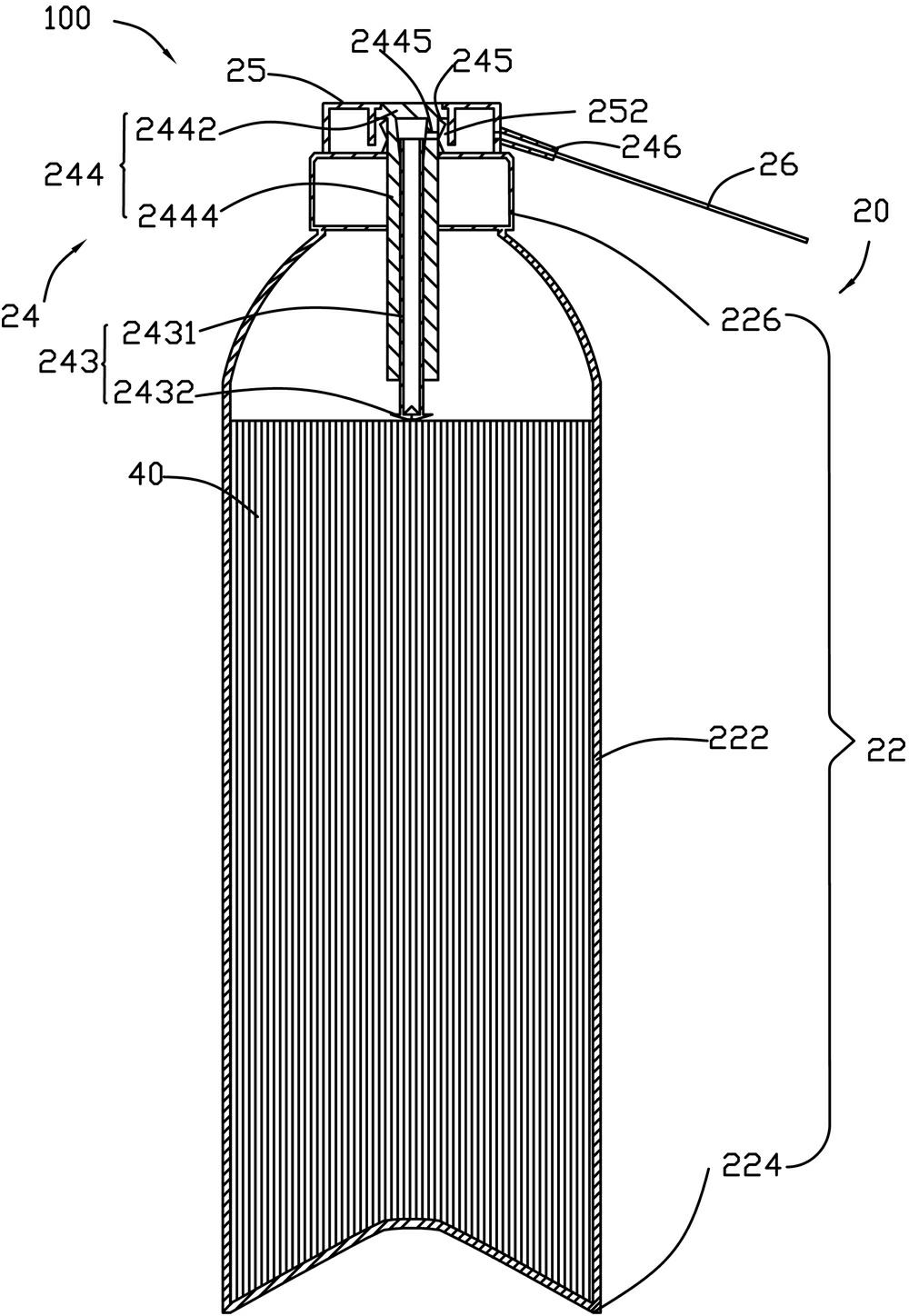

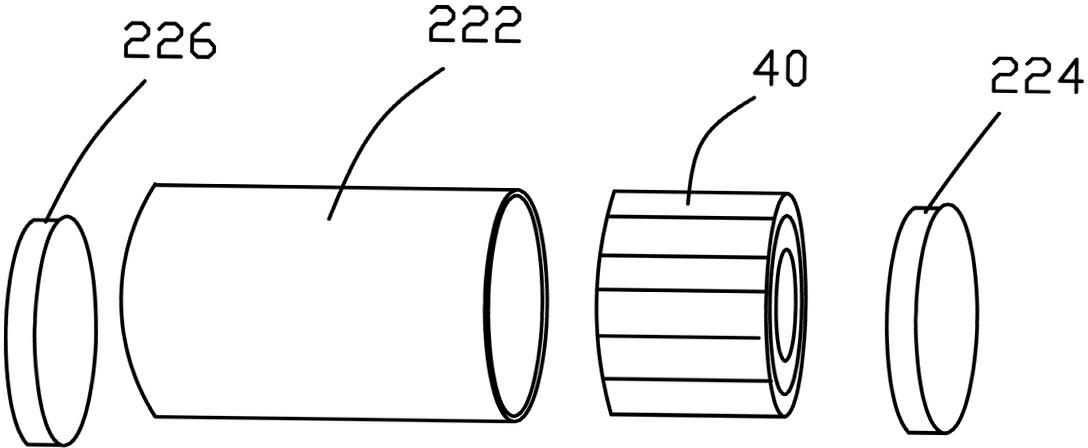

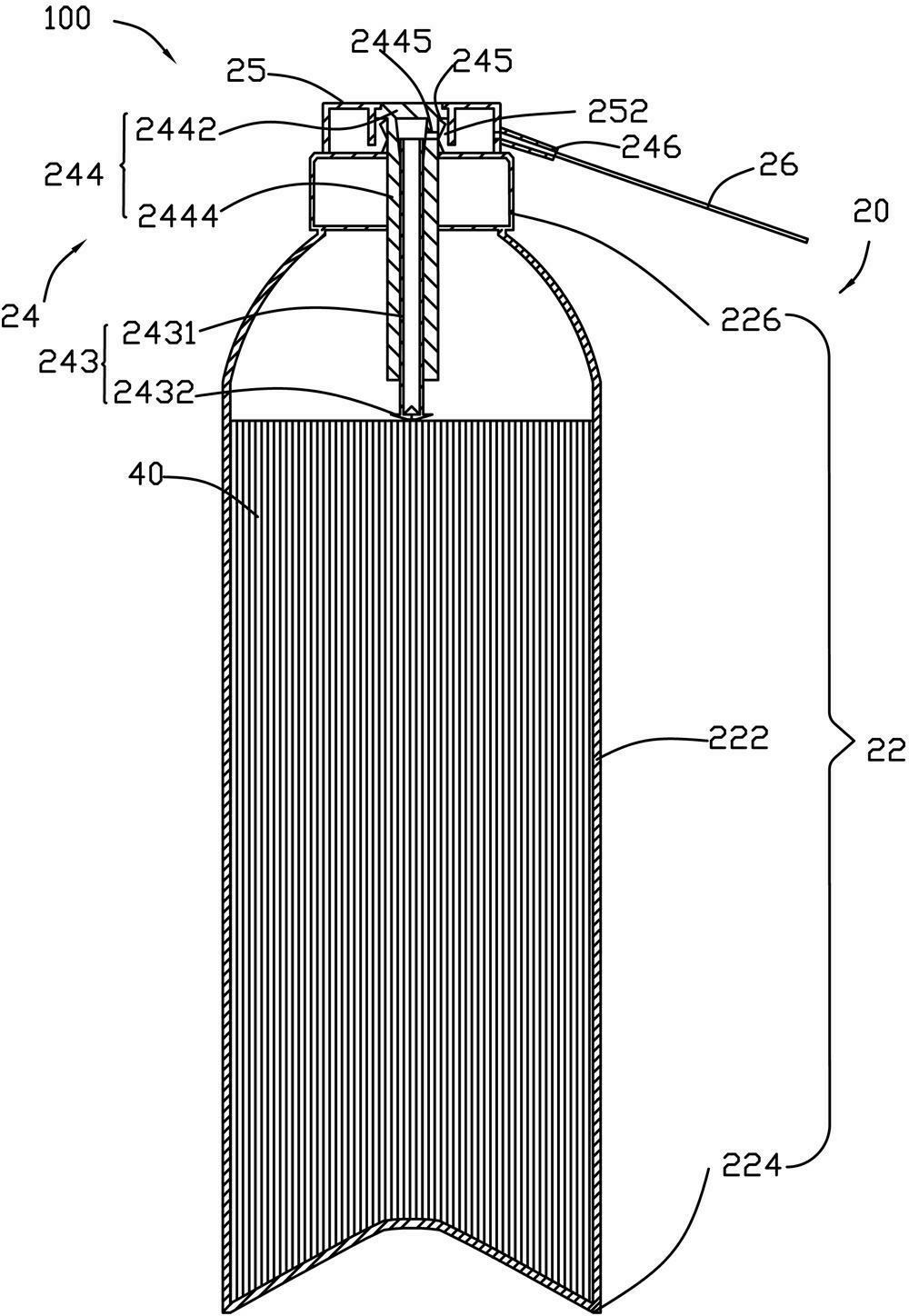

[0030] see figure 1 , the dust removal device 100 of the first preferred embodiment of the present invention is used for blowing dust. The dust removal device 100 includes an aerosol can 20 , and a propellant (not shown in the figure) and an adsorbent 40 assembled in the aerosol can 20 . The aerosol can 20 includes a can body 22 , a valve body 24 , a gland 25 and a conduit 26 . The tank body 22 can be made of multiple metal sheets, such as iron sheets, aluminum sheets and the like. The tank body 22 includes a cylinder body 222 , a tank bottom 224 and a tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com