Pressing type temperature-sensitive color-changing perfume bottle

A temperature-sensitive discoloration and perfume bottle technology, which is applied in the field of perfume bottles, can solve problems such as lack of locking function, too strong smell, and uncontrollable perfume spray volume, so as to increase attention, avoid waste, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

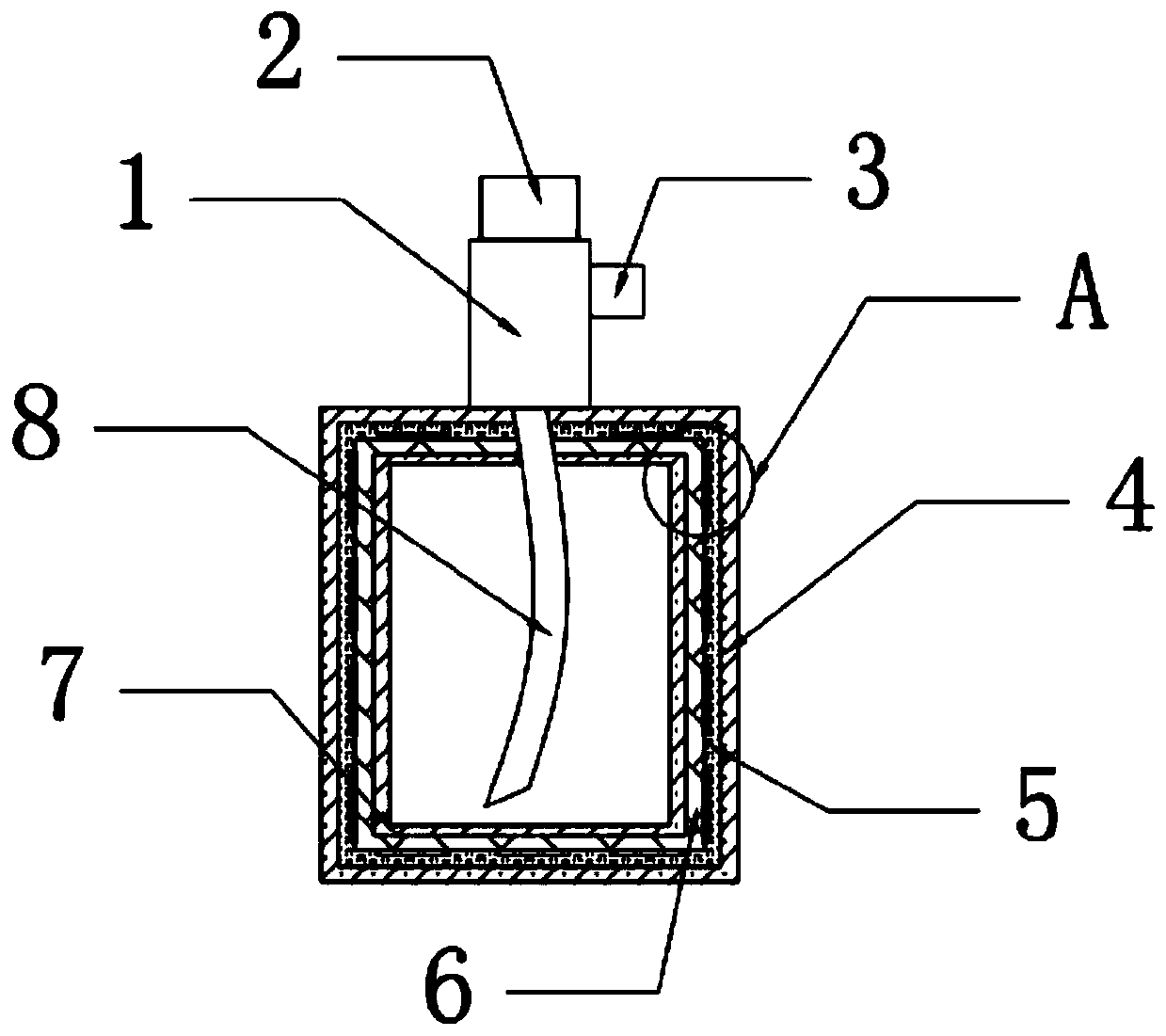

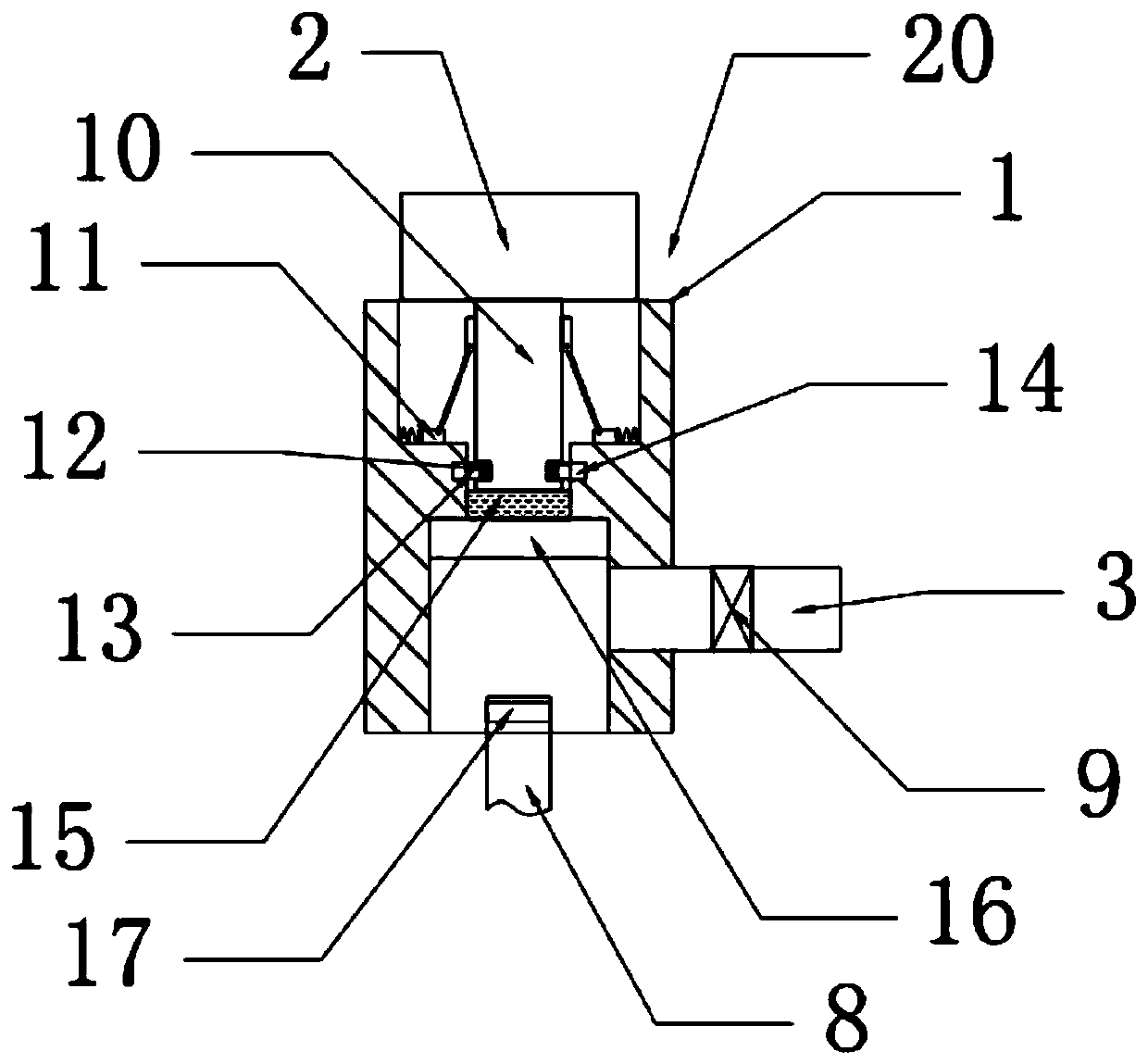

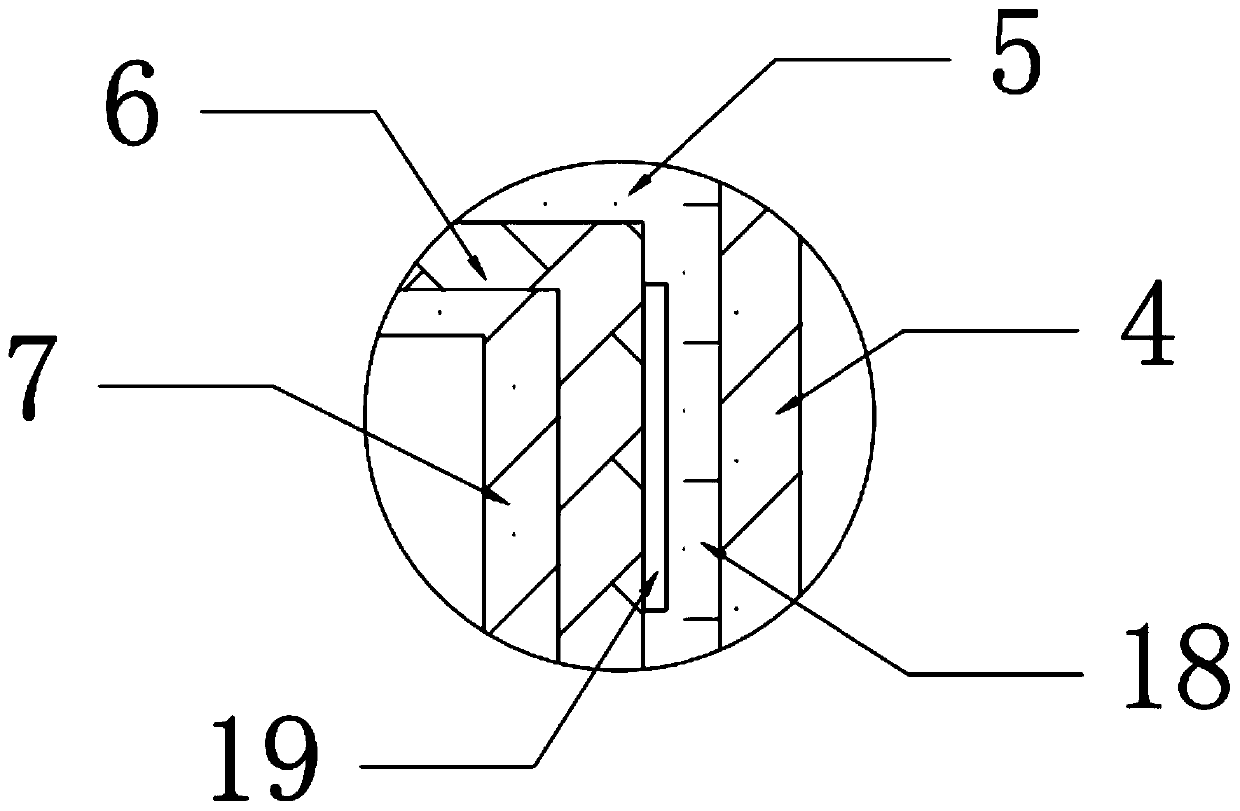

[0024] see Figure 1~3 , in an embodiment of the present invention, a push-type temperature-sensitive color-changing perfume bottle, including a first glass layer 4, a color-changing layer 5 and a pressing device 20, the top of the first glass layer 4 is provided with a pressing device 20, and the pressing device 20 is provided with a water outlet pipe 8 at the bottom, the water outlet pipe 8 is fixedly connected with the pressing device 20 and extends into the perfume bottle, the inside of the first glass layer 4 is provided with a discoloration layer 5, and the inside of the discoloration layer 5 is provided with a partition The thermal layer 6 can prevent the volatilization of the perfume in the perfume bottle due to the high external temperature by setting the thermal insulation layer 6. The inner side of the thermal insulation layer 6 is provided with a second glass layer 7, and the first glass layer 4 and the second glass layer 7 are made of toughened glass, which is use...

Embodiment 2

[0028] A perfume bottle, comprising the push-type temperature-sensitive color-changing perfume bottle described in Example 1.

[0029] The push-type temperature-sensitive color-changing perfume bottle can prevent the perfume in the perfume bottle from volatilizing due to excessive external temperature by setting the heat insulation layer 6, and can realize the fixing of the pressing head 2 by setting the clamp block 13 and the clamp groove 14, avoiding the perfume bottle. Because unconscious pressing causes the waste of perfume, by setting the flow controller 9, the amount of perfume spray can be effectively controlled, reducing unnecessary waste. It looks more dazzling under the light, which is beneficial to improve the attention of the perfume bottle.

[0030]The working principle of the present invention is: rotate the pressing head 2, the pressing head 2 drives the telescopic rod 10 to rotate, and the telescopic rod 10 drives the block 13 to rotate. The pressing head 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com