Patents

Literature

33results about How to "Control the amount of ejection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

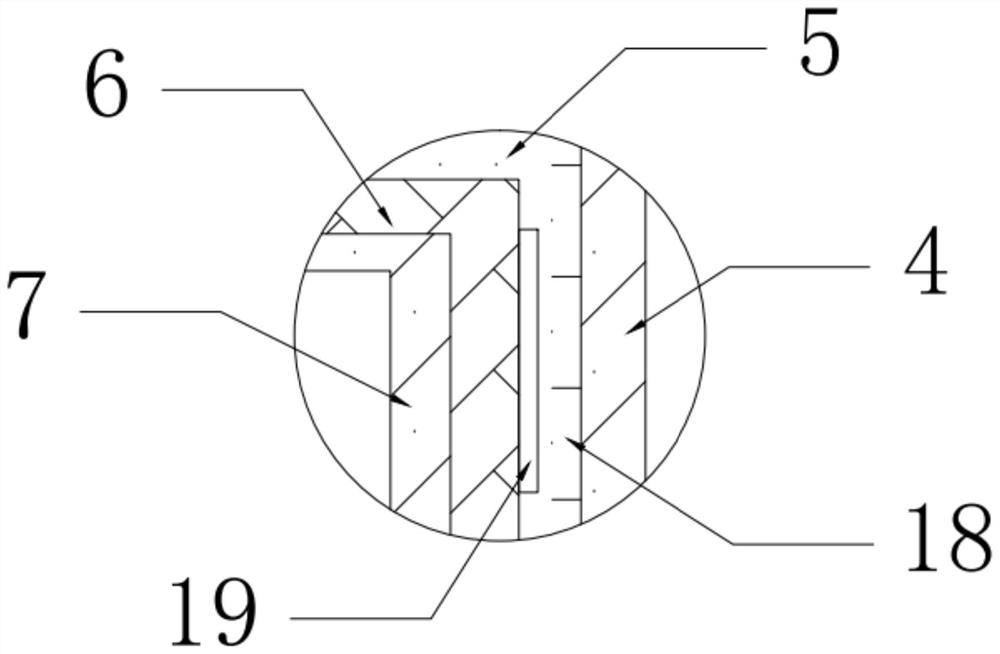

Emulsification device and emulsification method

InactiveCN105582828AAccurate ejection volumeAccurate control of ejection volumeFlow mixersMixing methodsEmulsionEngineering

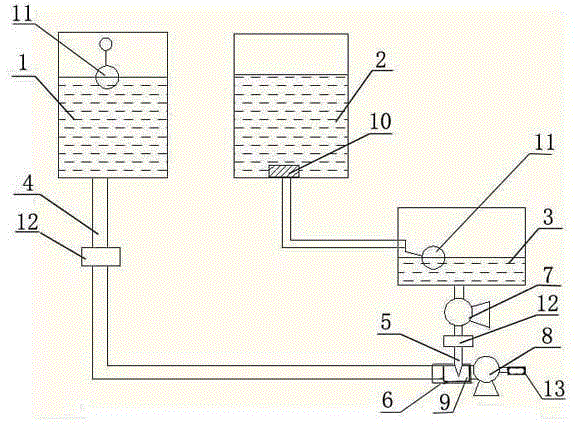

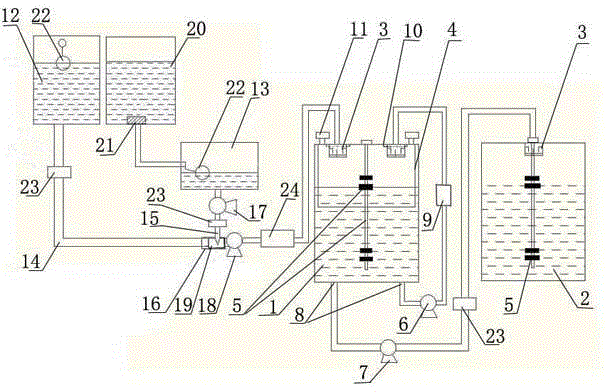

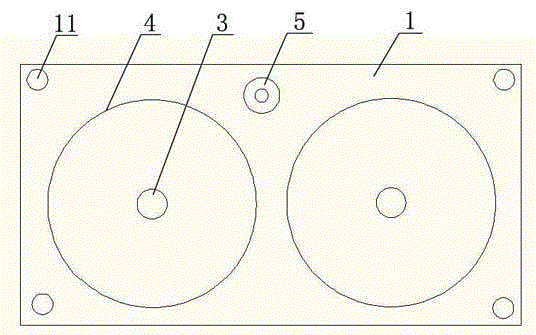

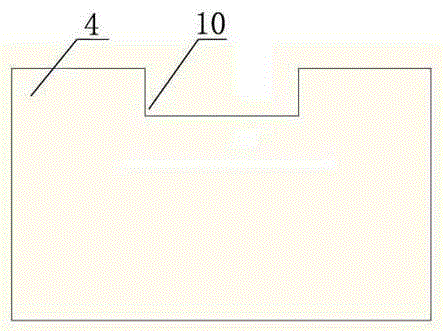

The invention provides an emulsification device and an emulsification method. The emulsification device comprises a water tank, an emulsifier dispensing tank, a water pipe, an emulsifier conveyer pipe, a proportioner, an emulsifier pump and a transfer pump. The water tank is communicated with the proportioner through the water pipe. The emulsifier dispensing tank passes through the emulsifier pump through the emulsifier conveyer pipe to be communicated with a water distribution pipe of the proportioner. The emulsifier conveyer pipe is vertically inserted into the water distribution pipe in the inflow direction. An outlet end is positioned at the middle-lower part of the water distribution pipe, and diameter of the outlet end is small. An outlet of the proportioner is communicated with the transfer pump. Height in the vertical direction of the water tank and the emulsifier dispensing tank is higher than height of the proportioner. By the emulsification method, a uniformly-mixed emulsion can be prepared continuously. By the device and the method, continuous emulsification is realized, and the emulsification effect can reach the level of an emulsification homogenizer in the prior art. The device and the method have efficiency and emulsification quality, and have a good application prospect.

Owner:曾小强 +1

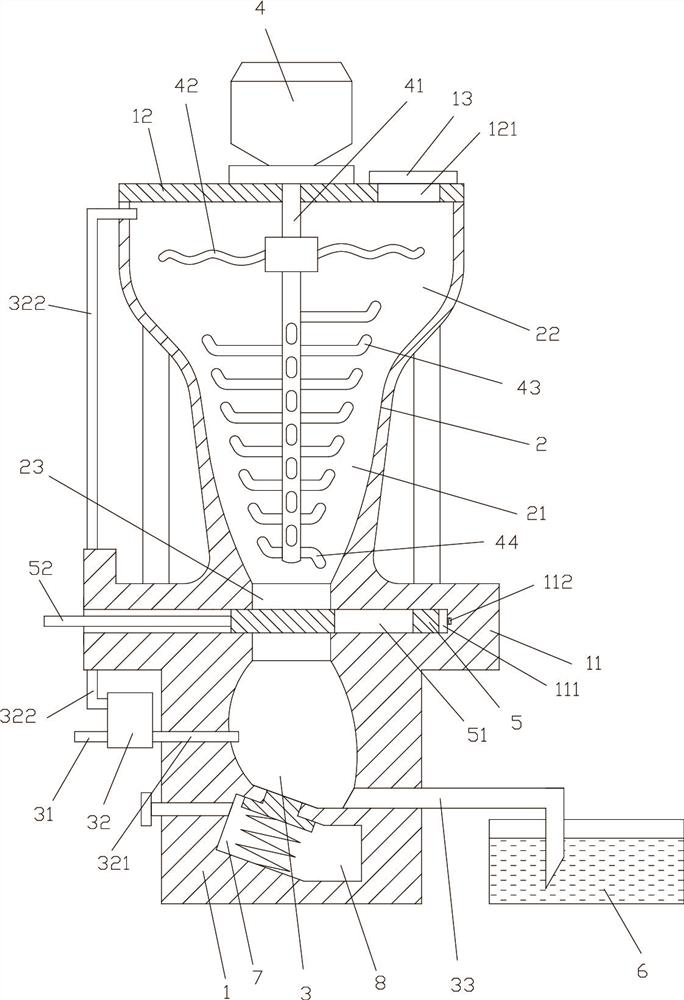

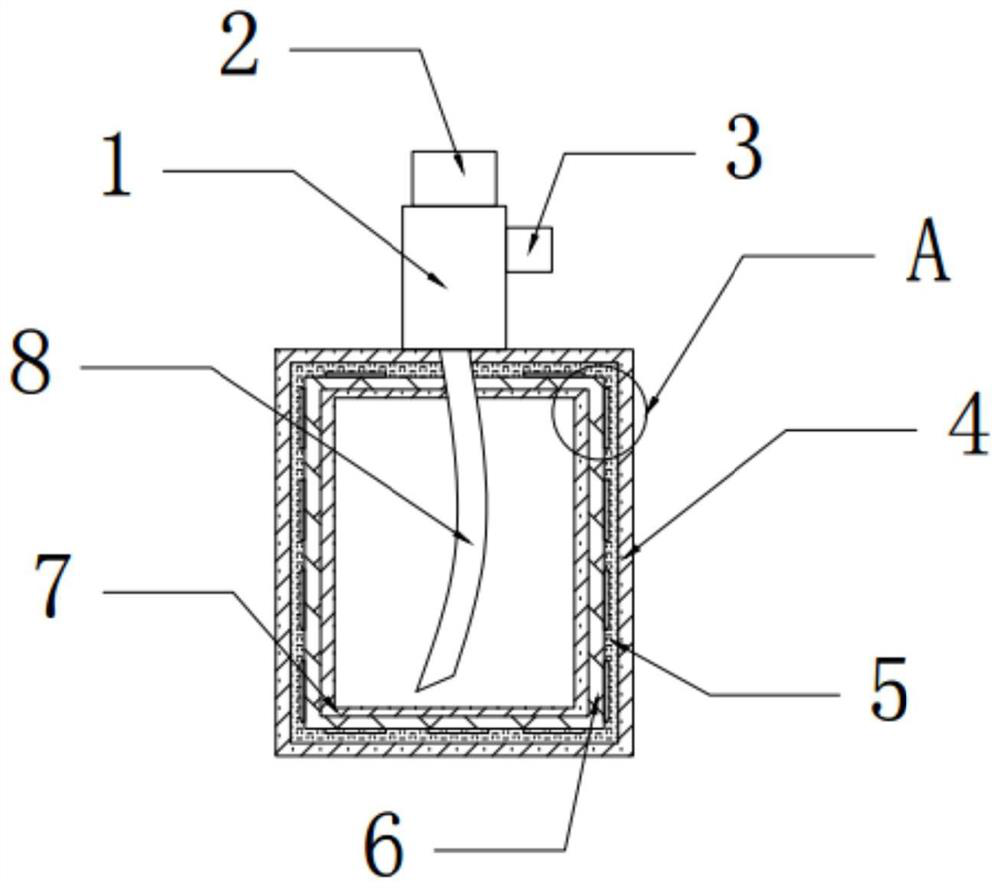

Novel liquid medicine atomization device for department of pediatrics

PendingCN113101469AGood treatment effectSimplify the operation processRotary stirring mixersTransportation and packagingMedical physicsBiomedical engineering

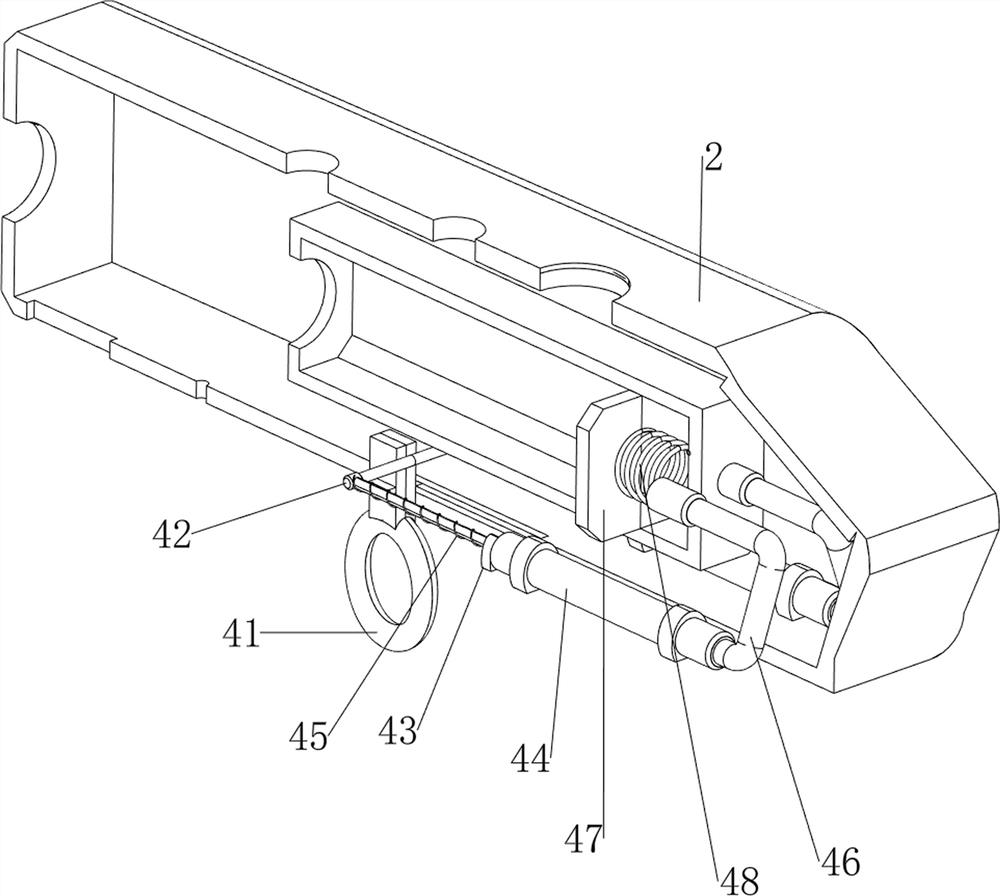

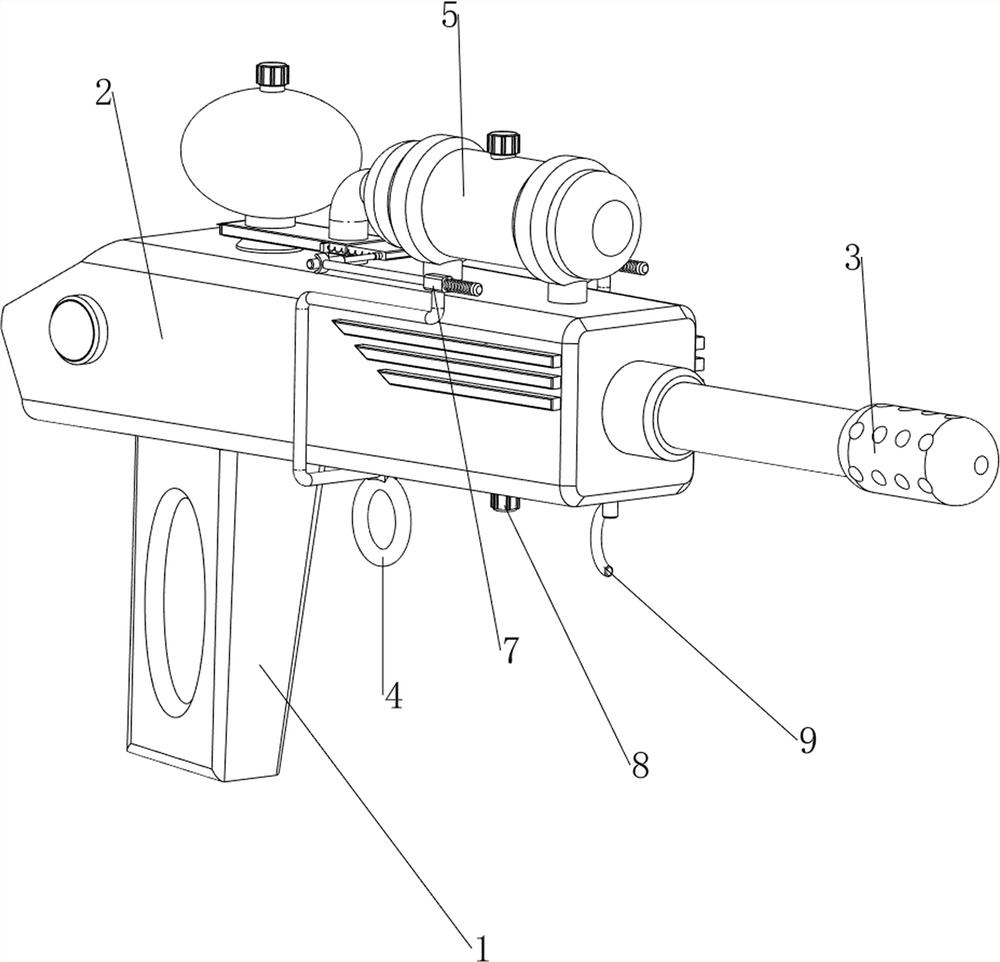

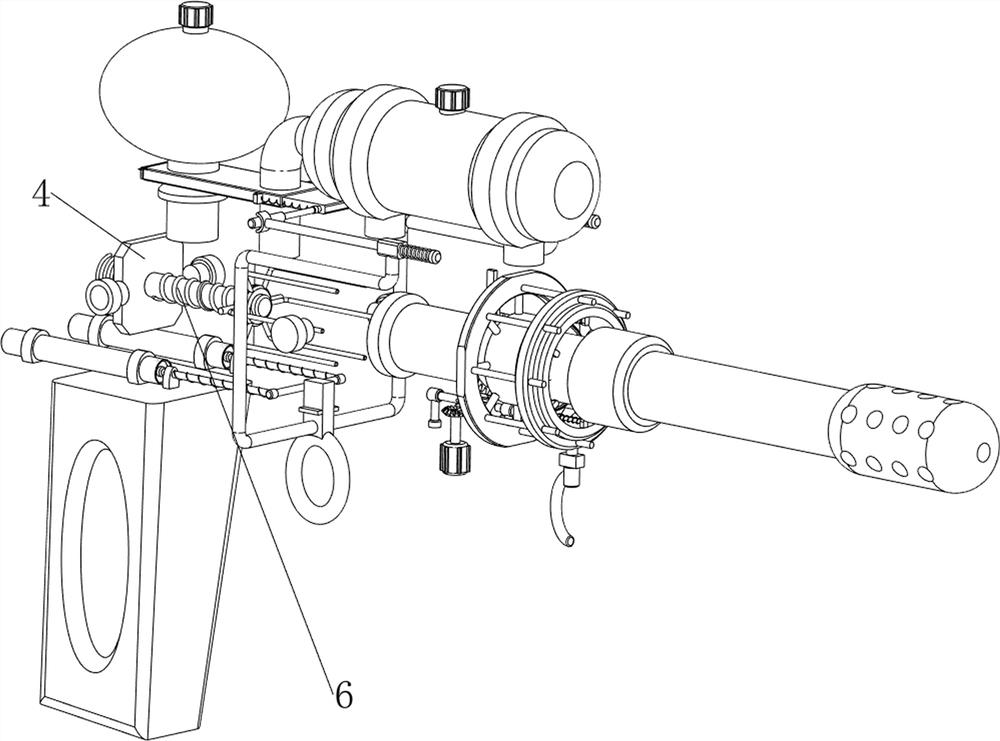

The invention relates to a novel atomization device, in particular to a novel liquid medicine atomization device for the department of pediatrics. The novel liquid medicine atomization device for the department of pediatrics can uniformly mix and stir two kinds of liquid medicine and can heat atomized liquid. The novel liquid medicine atomization device for the department of pediatrics comprises a grab handle, a frame body and a mist spray head, the frame body is arranged at the top of the grab handle, the mist spray head is arranged on the frame body, an extrusion mechanism is arranged in the frame body, and a medicine discharging mechanism is arranged at the top of the frame body. Through the arrangement of the extrusion mechanism and the medicine feeding mechanism, people can put two kinds of liquid medicine into the medicine feeding mechanism, the liquid medicine is atomized and sprayed out through the extrusion mechanism, and the treatment effect is better through the cooperation of the two kinds of medicine; the stirring mechanism and the pushing mechanism are arranged, the stirring mechanism can uniformly stir two kinds of mixed medicine liquid, the pushing mechanism is matched with the extrusion mechanism to drive the medicine discharging mechanism to move, and the operation process of people is simplified.

Owner:朱留芳

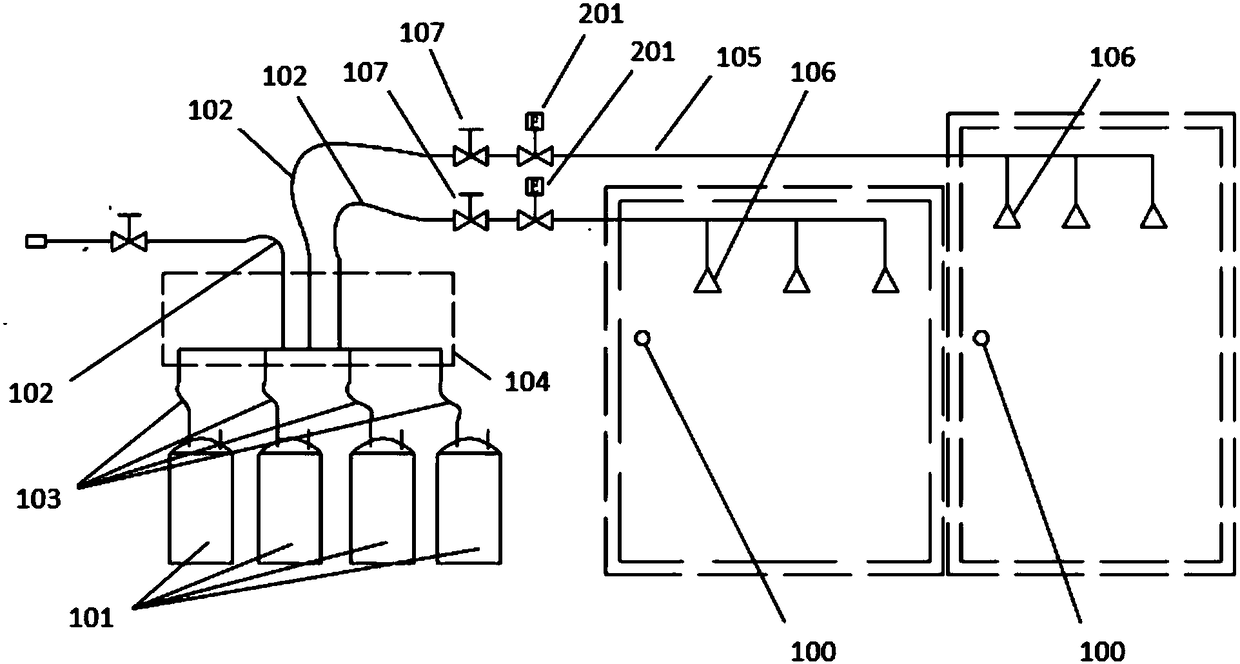

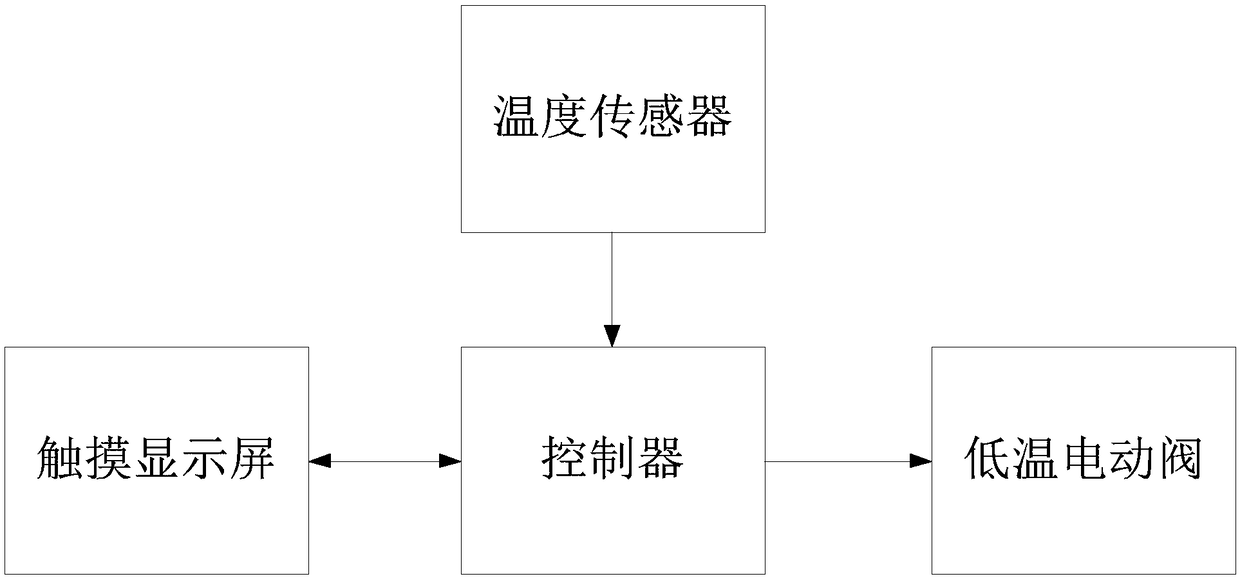

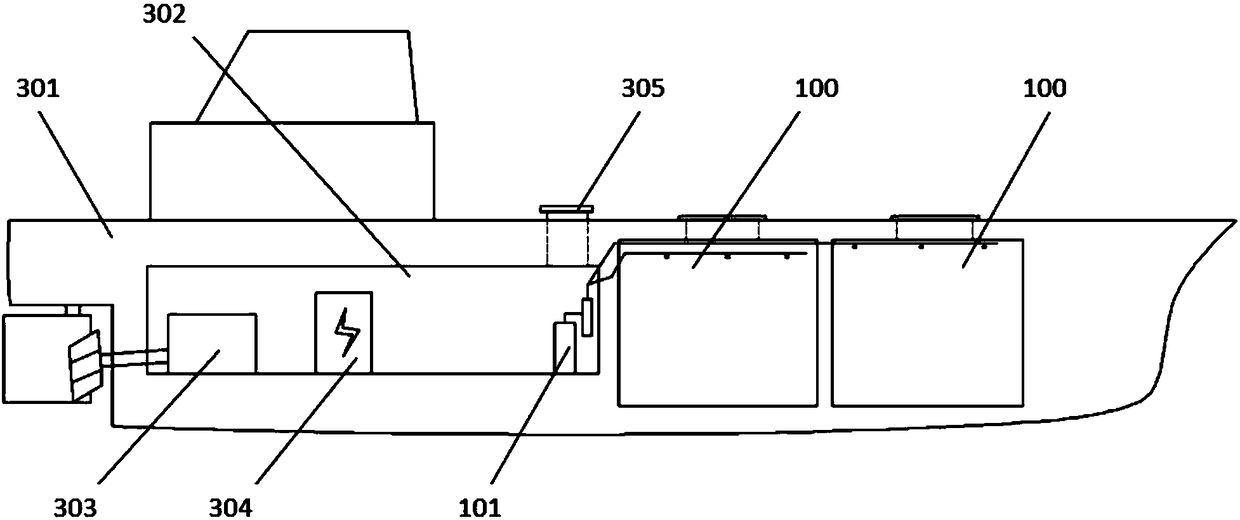

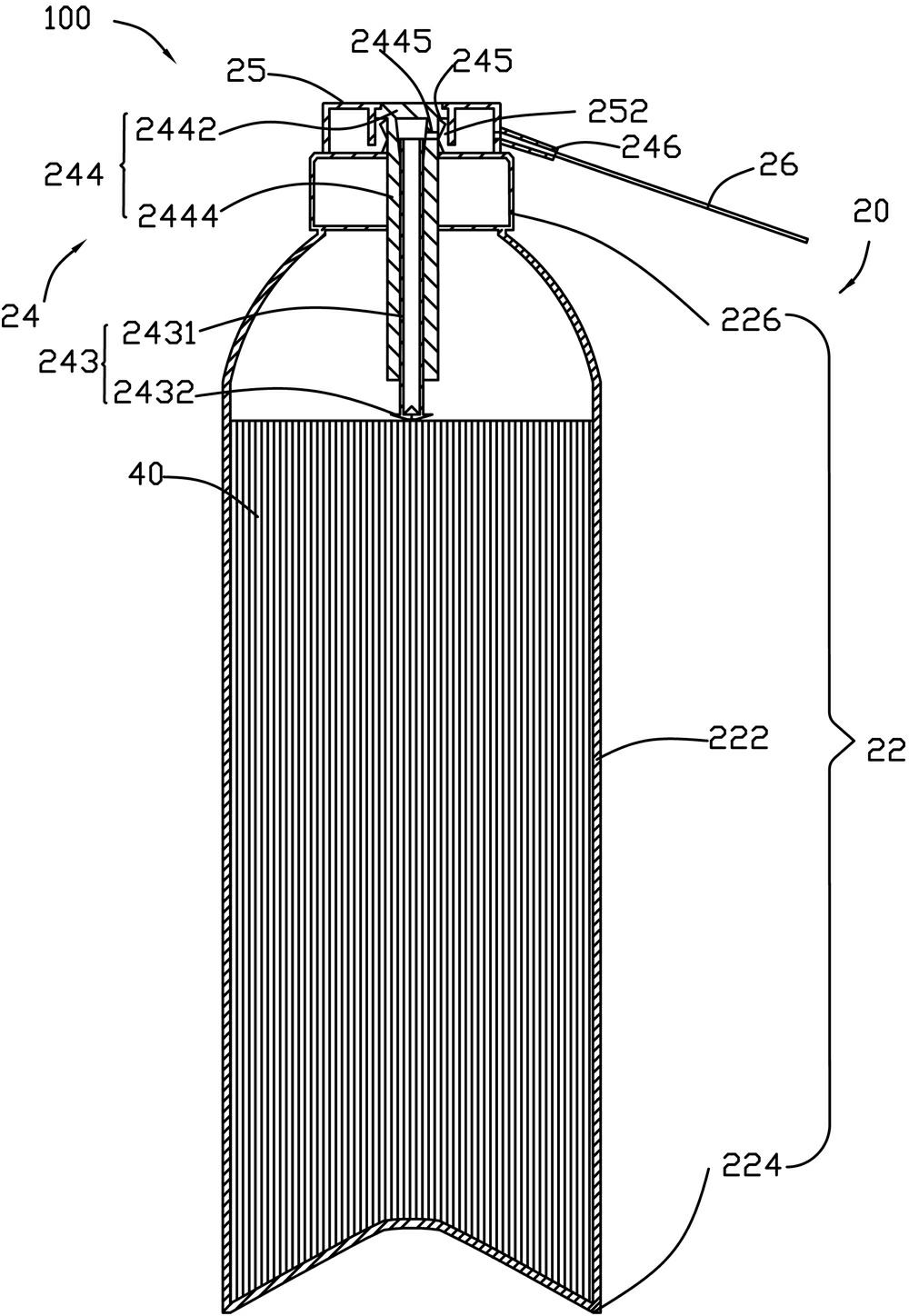

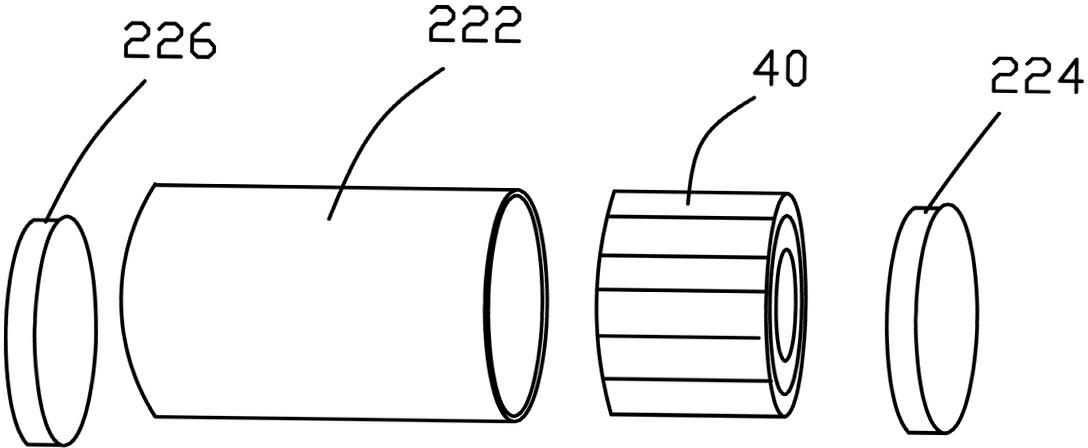

Liquid nitrogen refrigeration system and method for fishing boat

PendingCN108362058AControl the amount of ejectionHigh temperature control accuracyDomestic cooling apparatusLighting and heating apparatusTemperature controlProcess engineering

The invention discloses a liquid nitrogen refrigeration system and method for a fishing boat. The system comprises a refrigerating chamber, a liquid nitrogen dewar flask, a liquid nitrogen conveying pipeline, a liquid nitrogen spraying pipeline, a low-temperature electric valve, a controller, a touch display screen and a temperature sensor; the method comprises the following steps that a target temperature of the refrigerating chamber is input, and a starting temperature of the refrigerating chamber is collected; the duty ratio of PWM waves used for controlling the low-temperature electric valve is calculated according to the input target temperature and the initial temperature of the refrigerating chamber; the controller controls the low-temperature electric valve to be conducted throughthe PWM waves, so that the liquid nitrogen is sprayed into the refrigerating chamber to complete refrigeration; and the controller is used for closing the low-temperature electric valve after the temperature of the refrigerating chamber reaches the target temperature. According to the liquid nitrogen refrigerating system and method, the spraying amount of liquid nitrogen is controlled through thePWM waves, and the temperature control precision of the liquid nitrogen refrigerating system can be effectively improved. The system and method can be widely applied to the technical field of refrigeration.

Owner:广州聚联物流有限公司

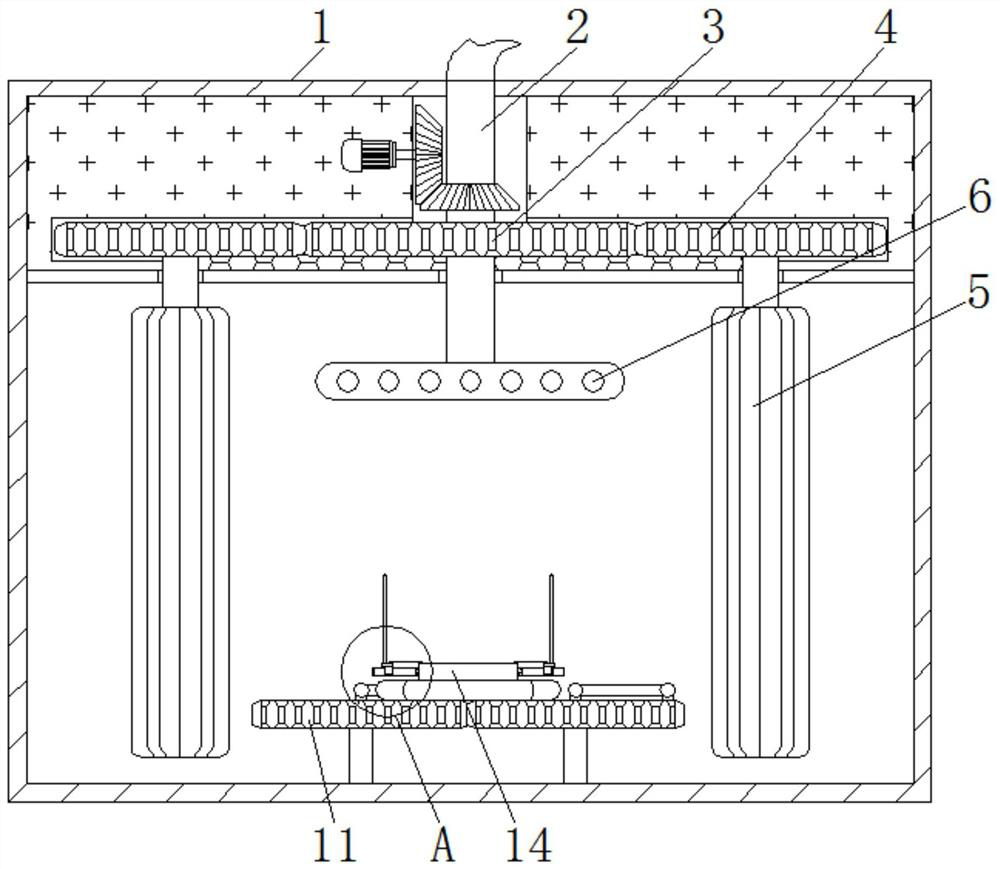

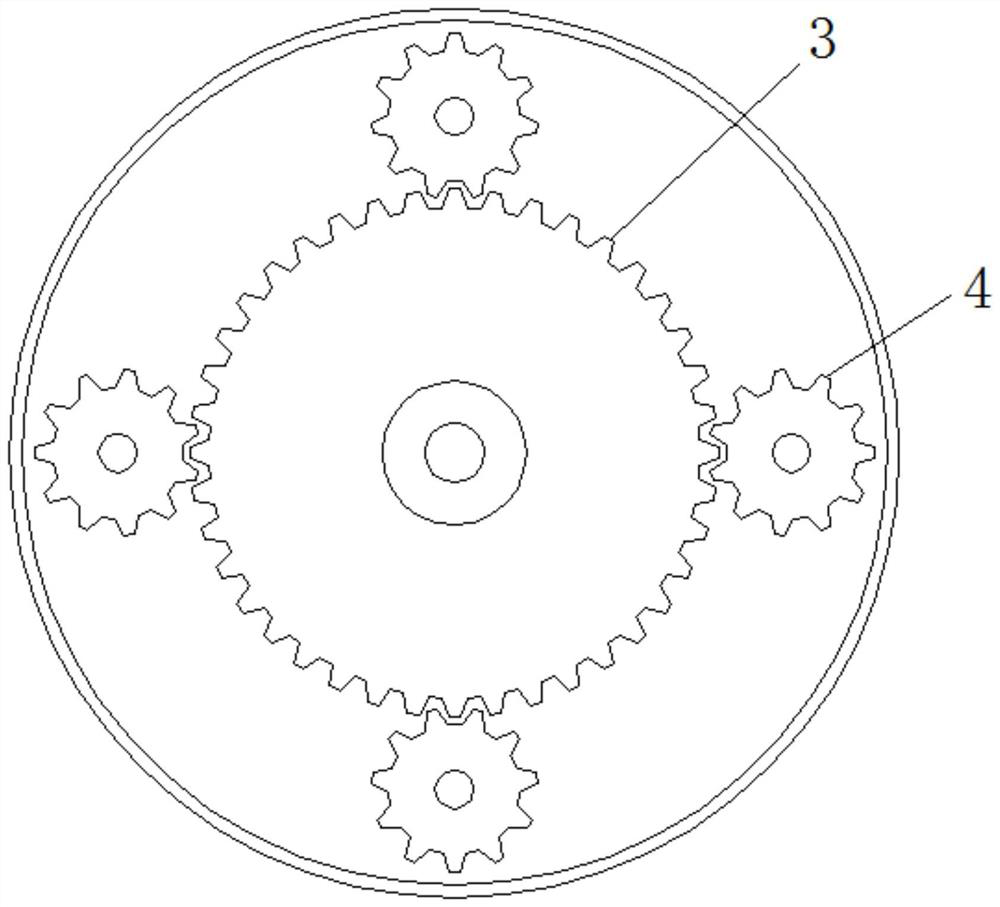

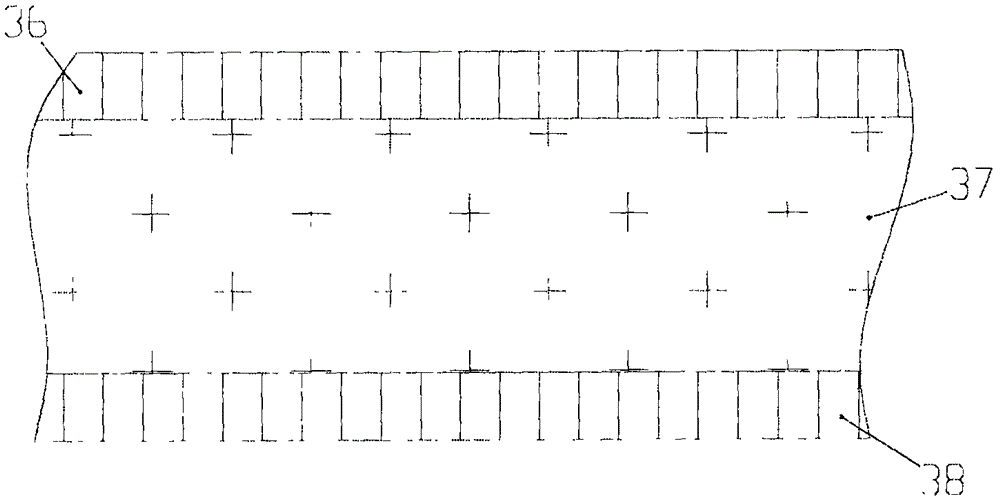

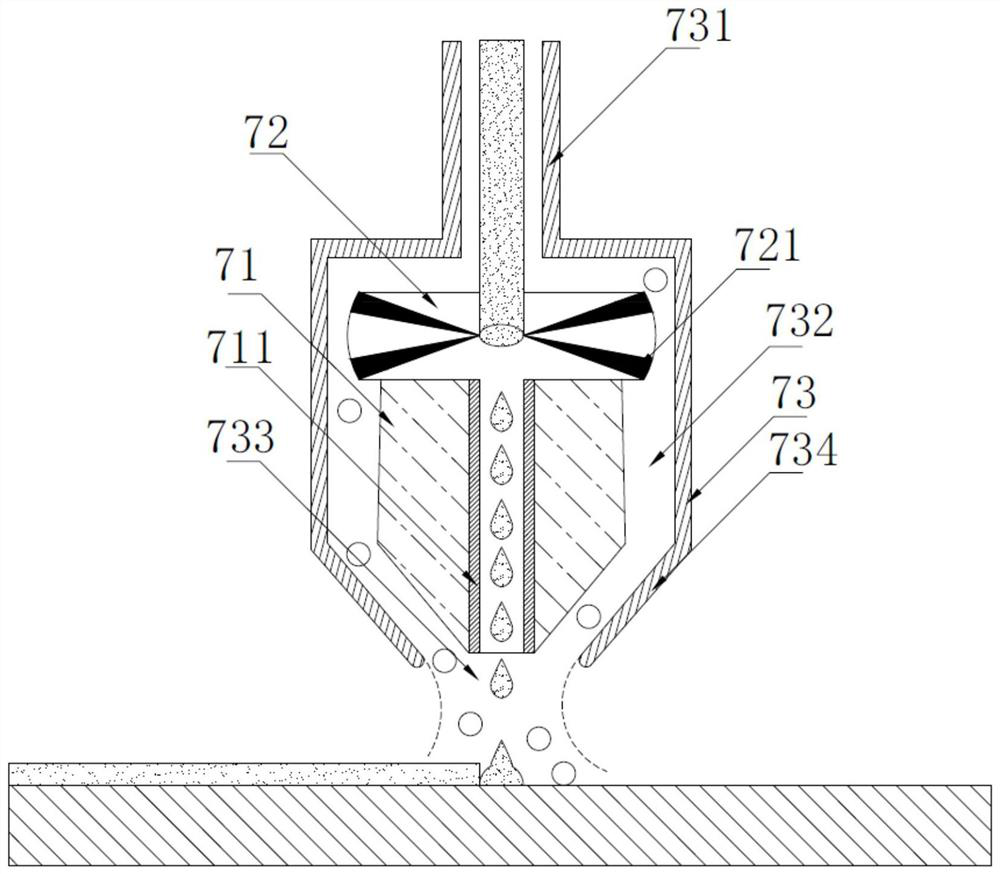

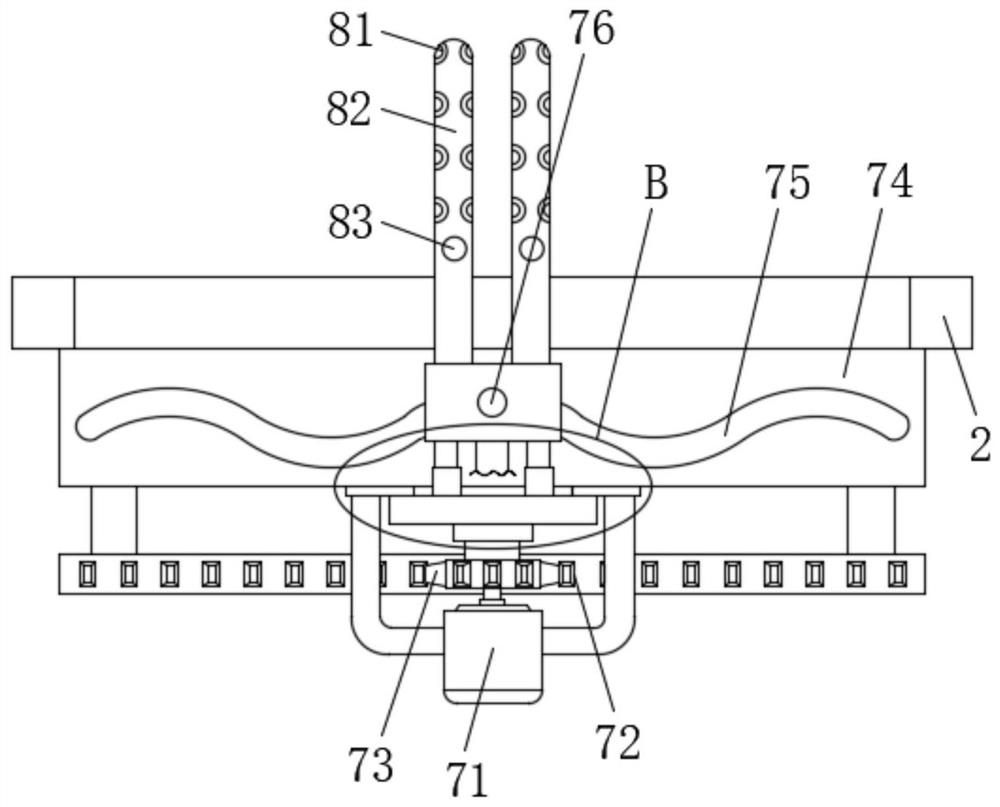

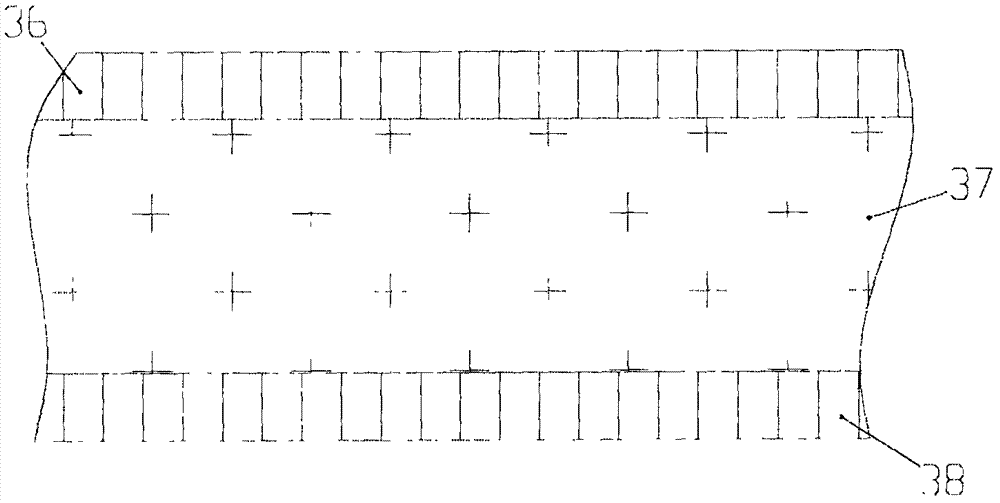

Yarn dyeing device uniform in dyeing and capable of controlling dye discharge

ActiveCN112411055AUniform dyeingControl outputTextile treatment machine arrangementsTextile treatment by spraying/projectingYarnMaterials science

The invention relates to the technical field of yarn dyeing, and discloses a yarn dyeing device that is uniform in dyeing and capable of controlling dye discharge. The yarn dyeing device comprises a shell, wherein a feeding pipe is fixedly installed in the middle of the top end of the shell, a sun wheel is fixedly installed on the surface of the feeding pipe, the edge of the sun wheel is connectedwith a planet wheel in an engaged mode, a stirring rod is fixedly connected to the interior of the planet wheel, a spray head is fixedly connected to the bottom end of the feeding pipe, a stirring ball is movably connected to the surface of the spray head, a spring is fixedly connected to the interior of the spray head, and a ball body is fixedly connected to the side, close to the edge of the spray head, of the spring. According to the yarn dyeing device uniform in dyeing and capable of controlling the dye discharge, the rotating speed of the spray head is used for controlling the amount ofsprayed dye, the amount of the sprayed dye can be controlled, left-right swing of a second rotating disc enables a fixing rod to conduct tightening treatment on different positions of a yarn roll periodically, and the yarn dyeing effect is better.

Owner:佛山市全顺来针织有限公司

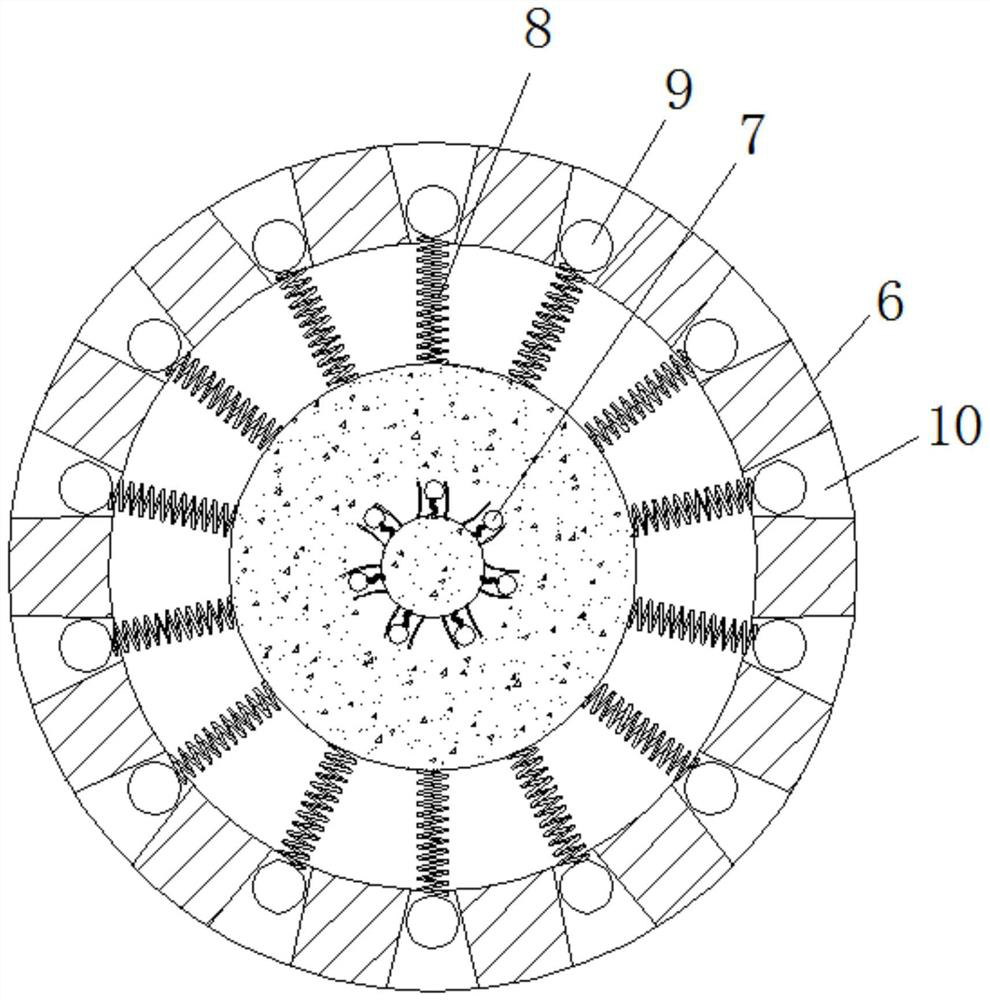

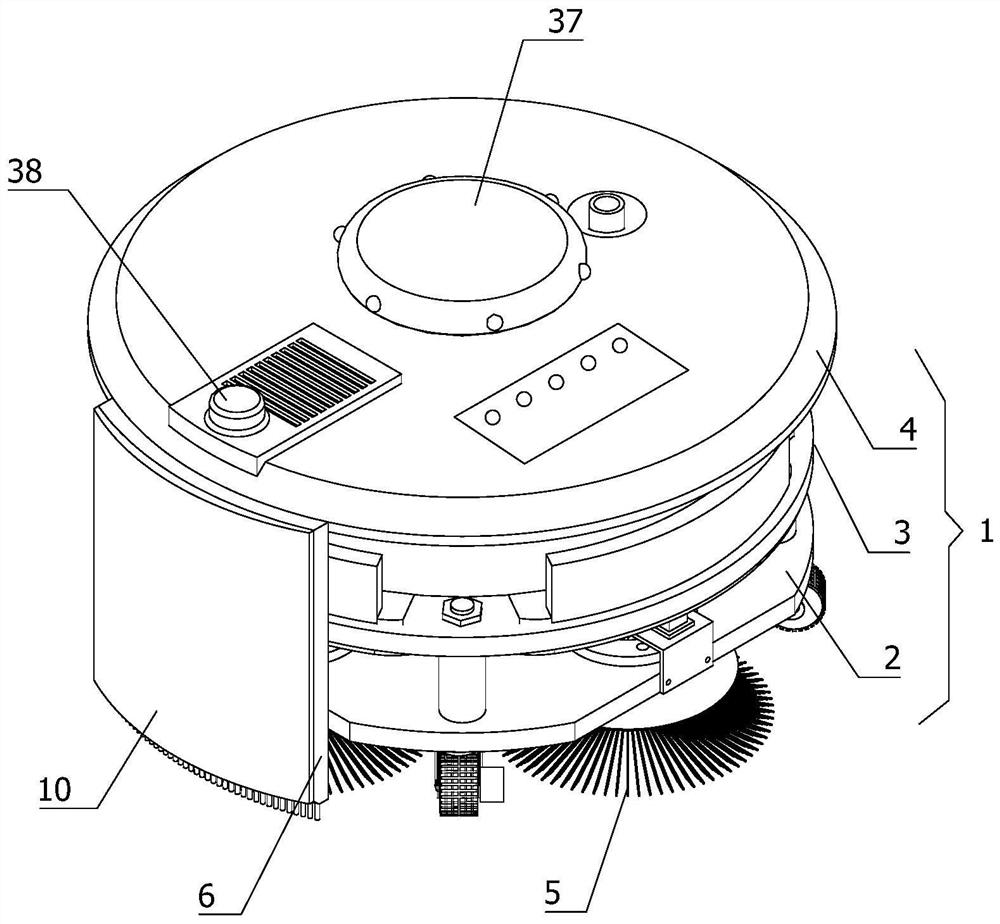

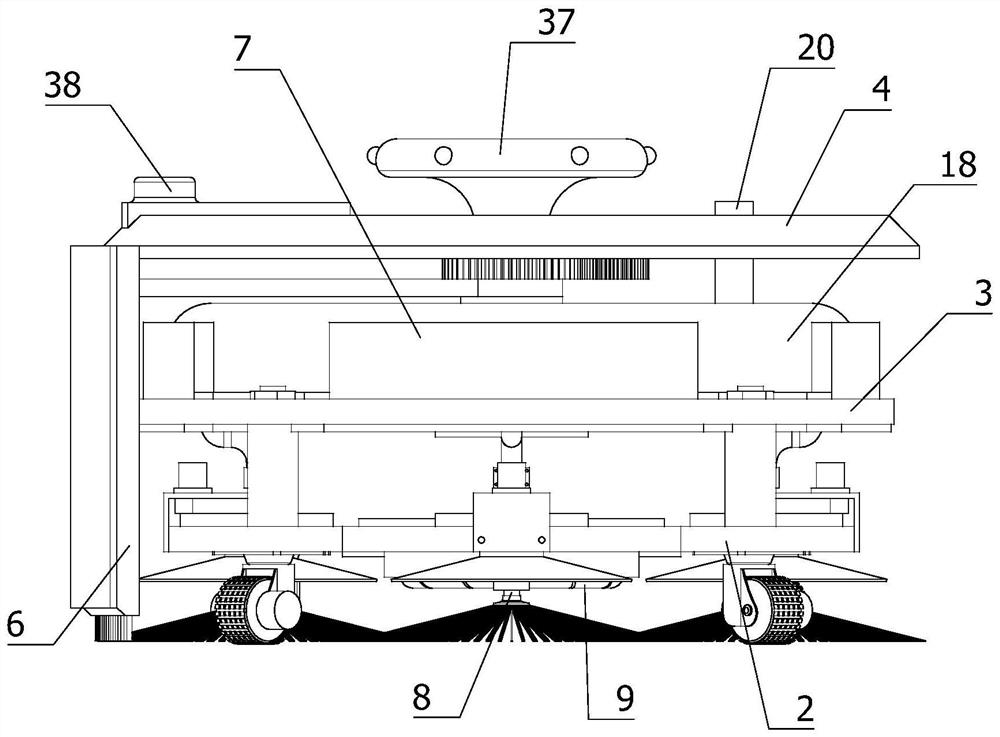

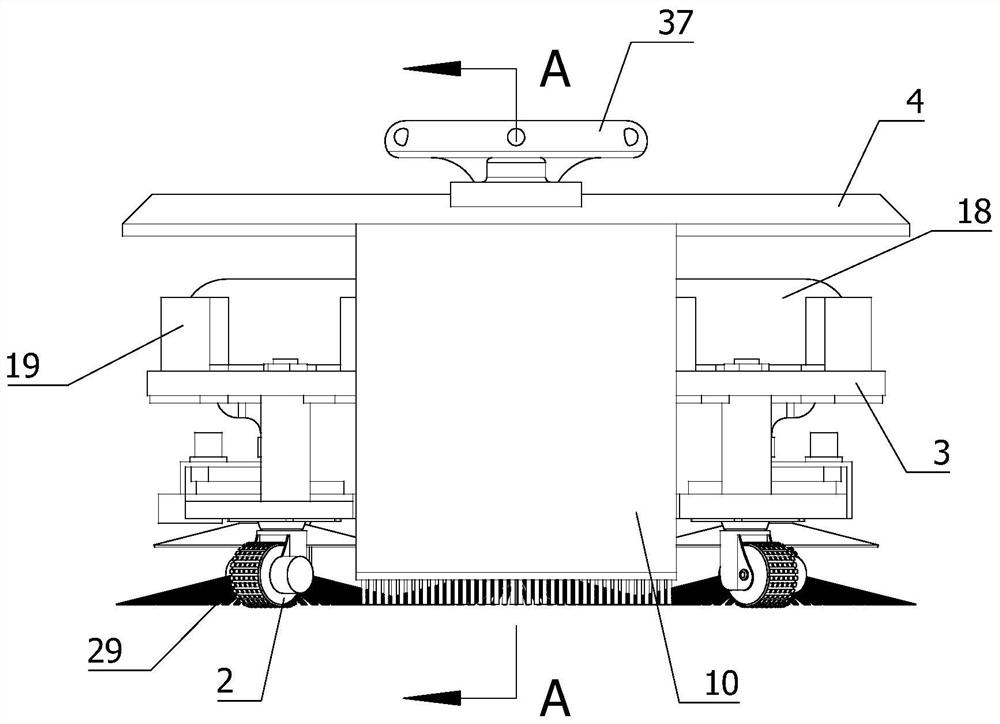

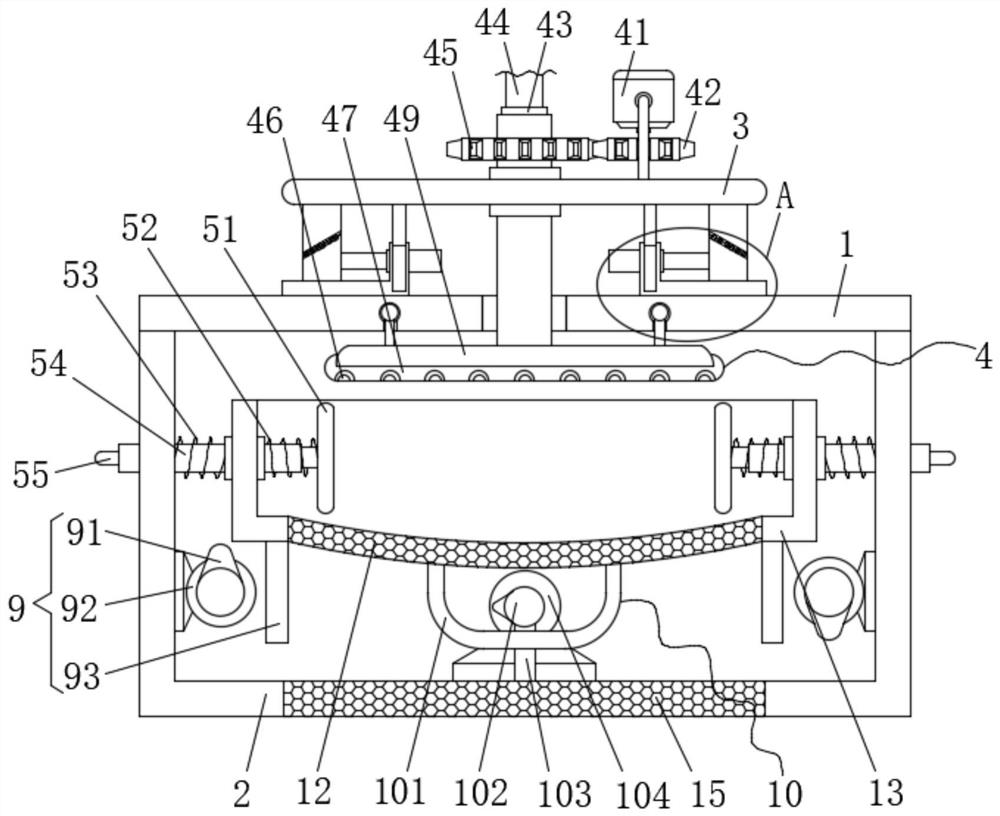

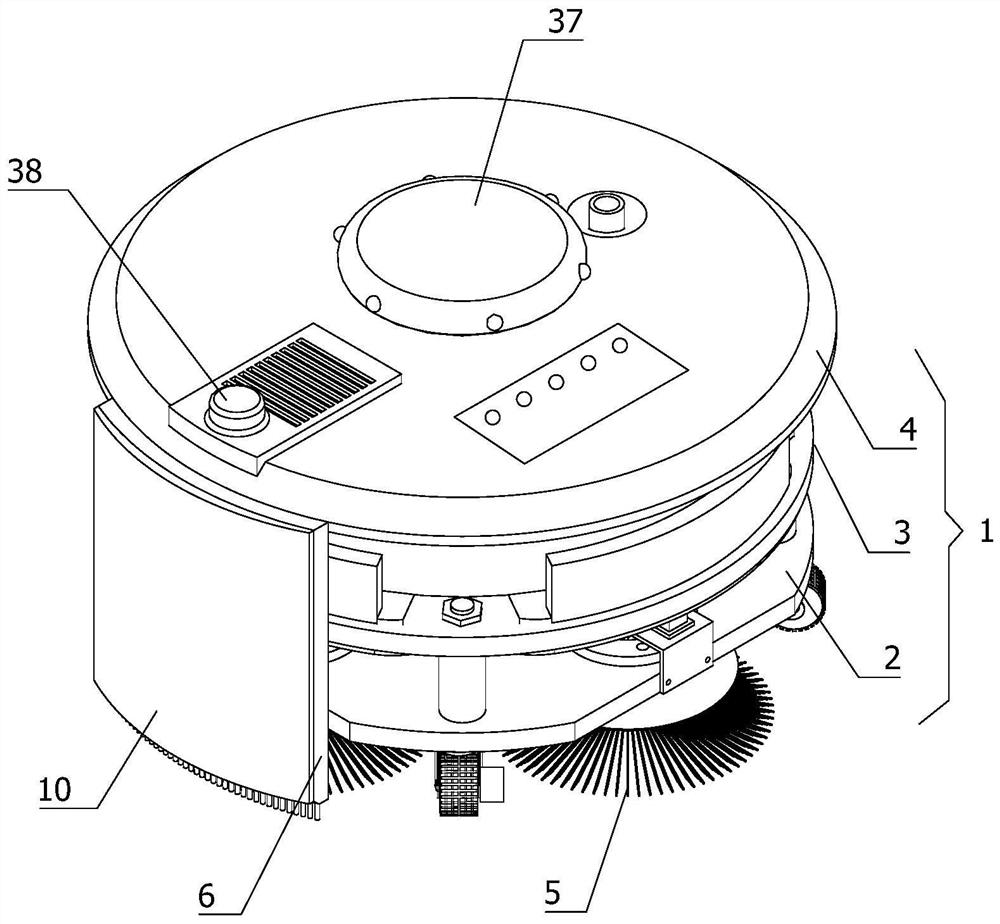

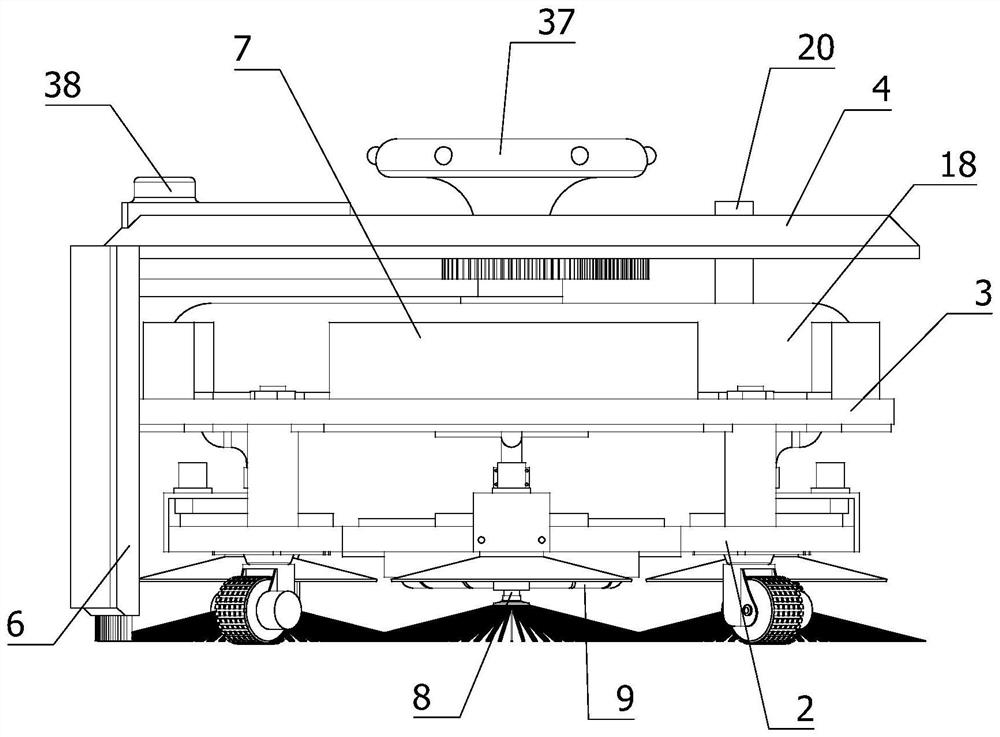

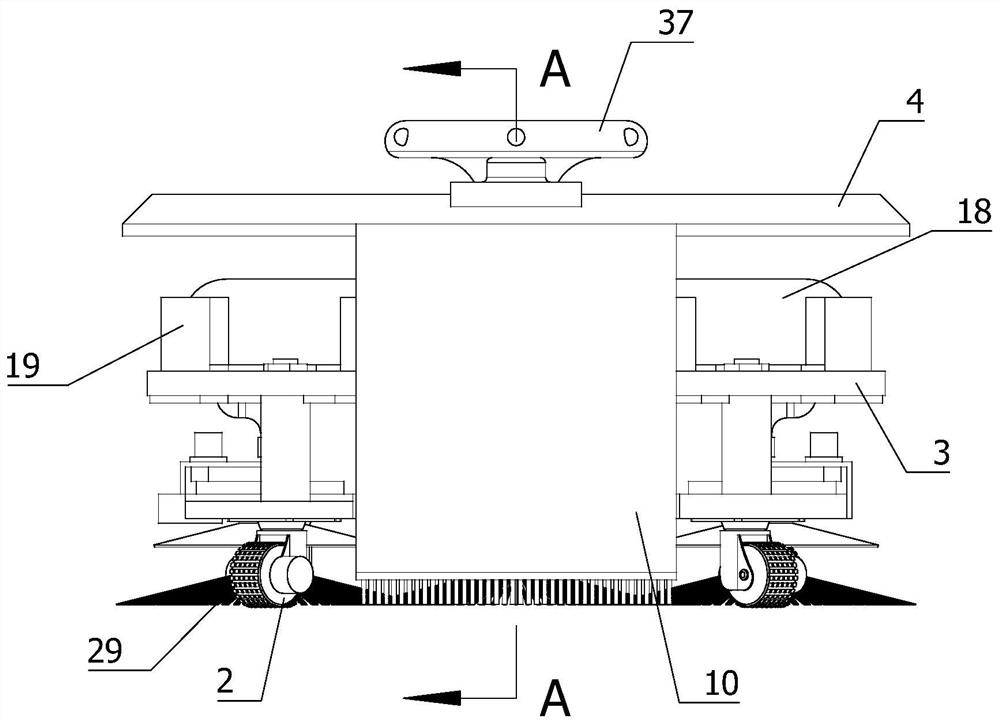

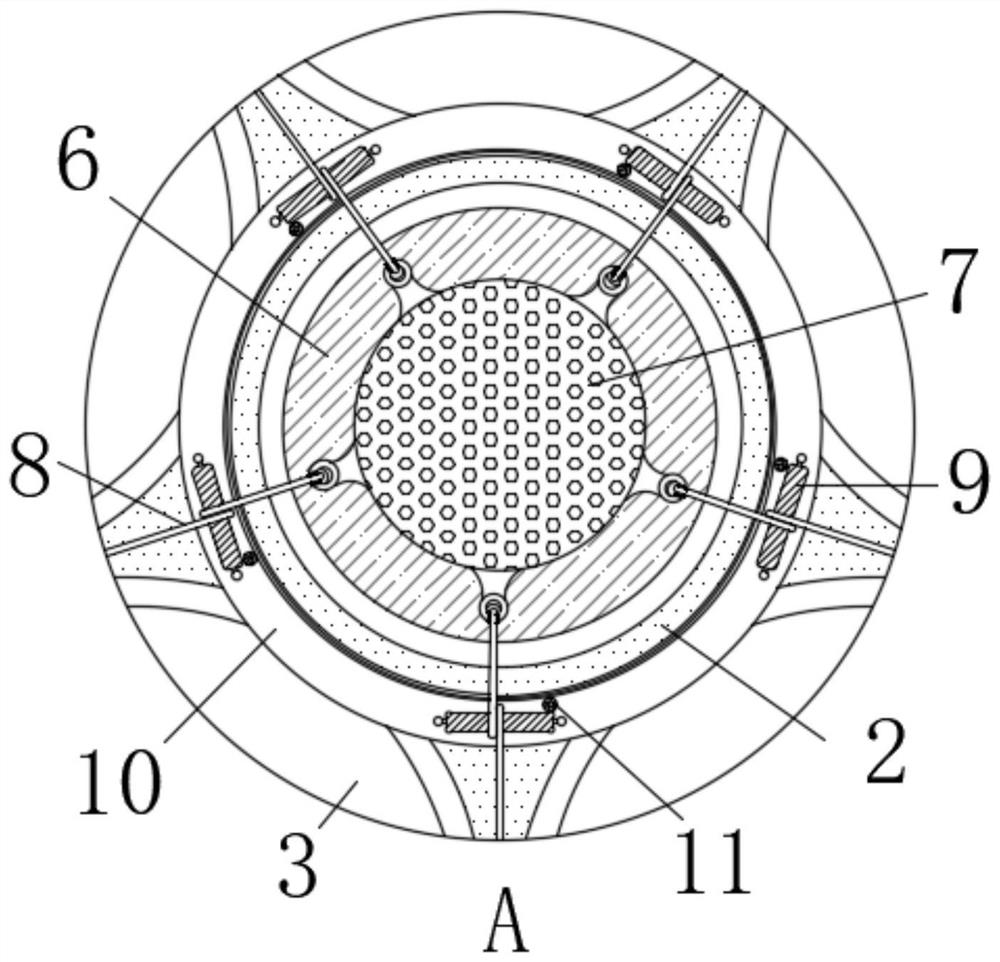

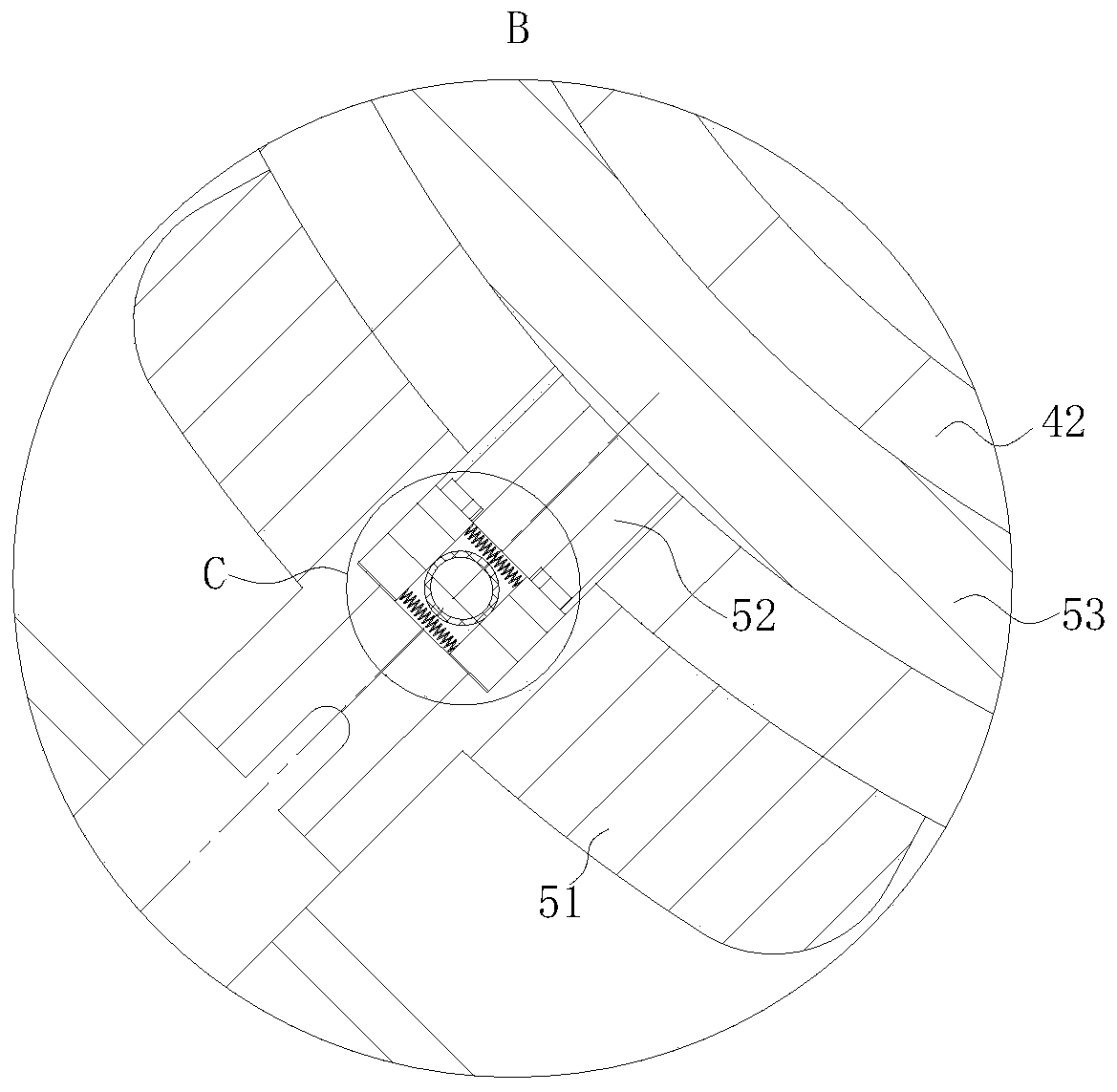

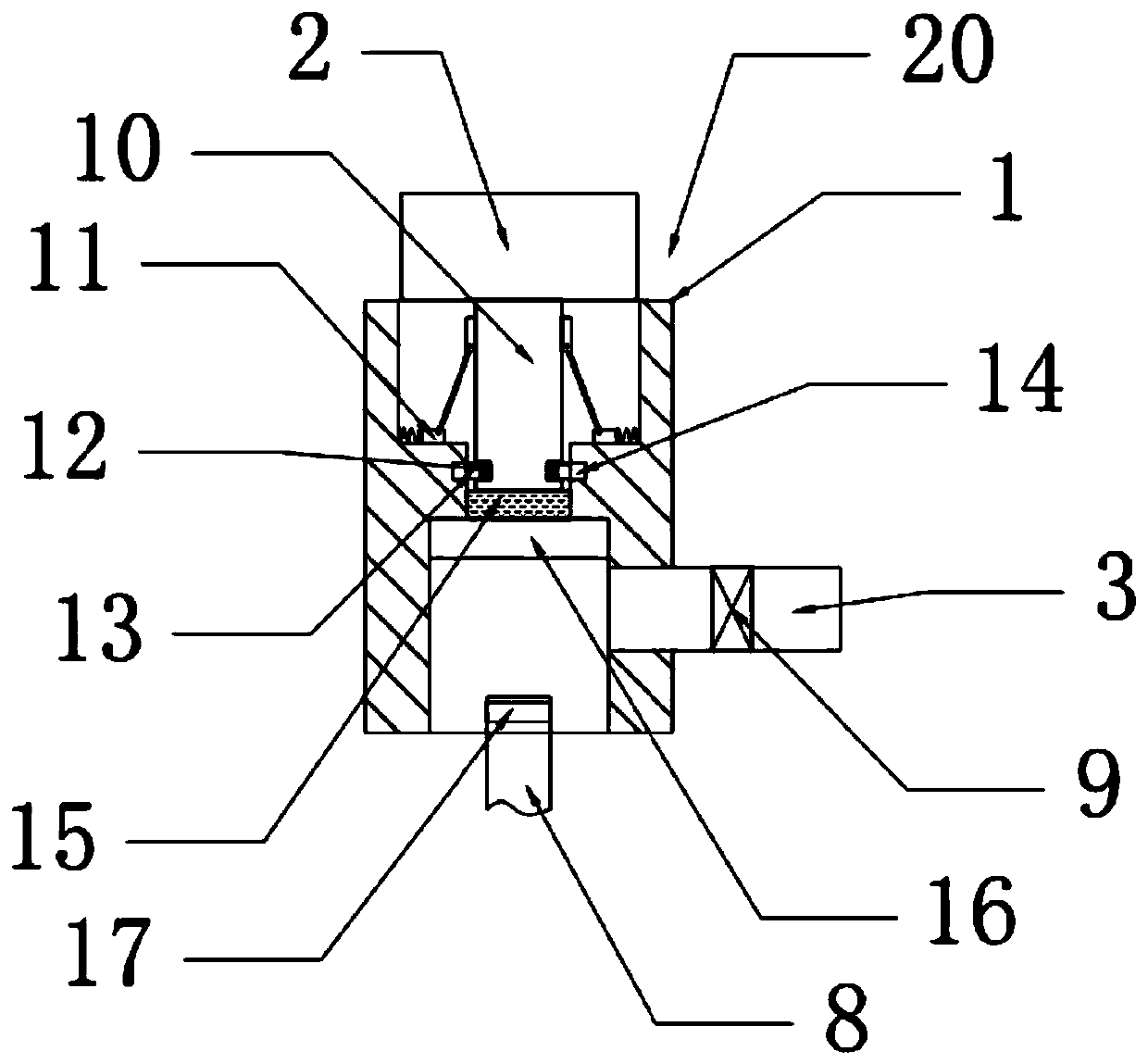

Automatic disinfection robot for ground of medical department

ActiveCN113842482AApply evenlyDo not polluteAutomatic obstacle detectionTravelling automatic controlMedical departmentEnvironmental engineering

The invention relates to the technical field of medical instruments, in particular to an automatic disinfection robot for ground of medical department. The automatic disinfection robot comprises a walking device, an alarm device and a disinfection device, the walking device is a disc-shaped robot, and the walking device is composed of a chassis walking vehicle, a middle end supporting disc and a top disc which are sequentially installed from bottom to top; the disinfection device comprises a uniform disinfection assembly and a baffle, the uniform disinfection assembly comprises a liquid supply mechanism, a liquid spraying mechanism and an air blowing fan. According to the automatic disinfection robot for the ground of the medical department, through cooperation between the walking device and the disinfection device, automatic and comprehensive disinfection of the ground of the medical department is achieved, and through blocking of the baffle on obstacle; the obstacles cannot be contaminated by disinfectant, the disinfectant only disinfects the floor, the disinfectant is evenly smeared through a liquid spraying mechanism and the air blowing fan, and even smearing of the disinfectant is guaranteed while the floor is comprehensively disinfected.

Owner:SOUTHWEST JIAOTONG UNIV +1

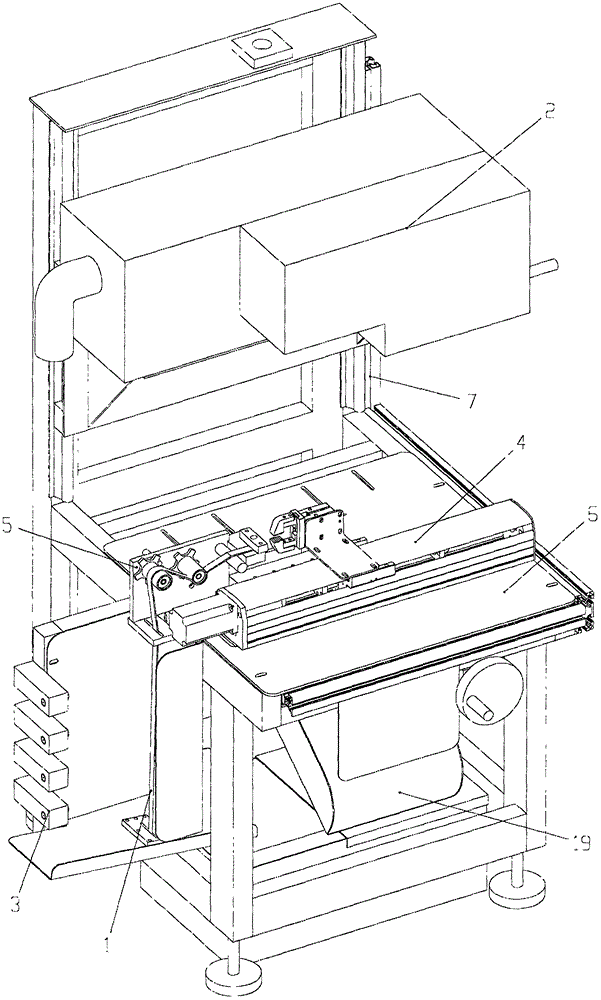

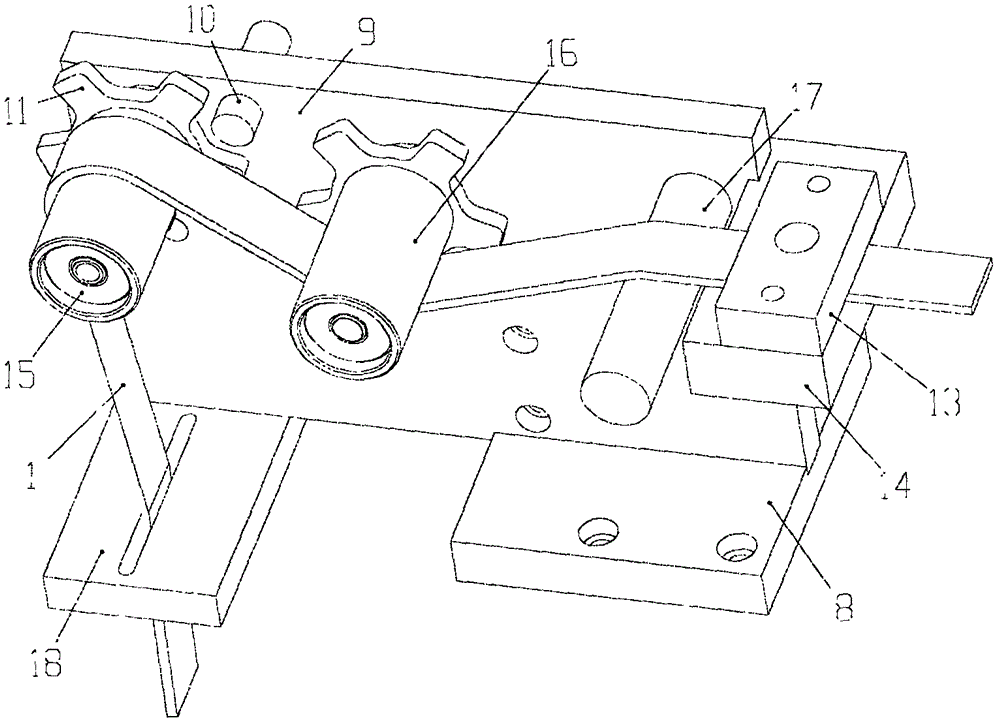

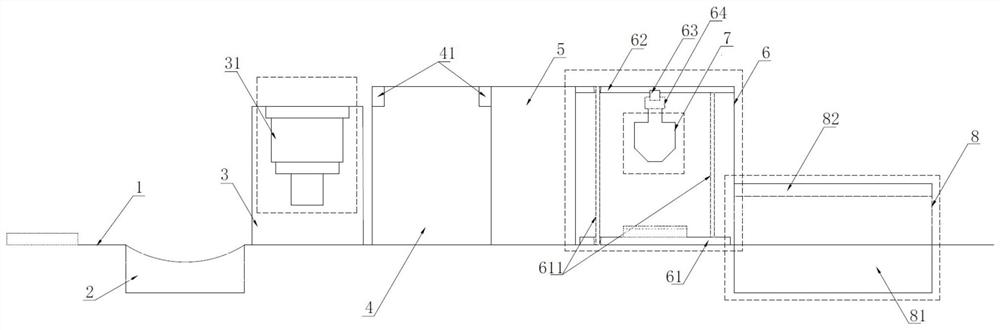

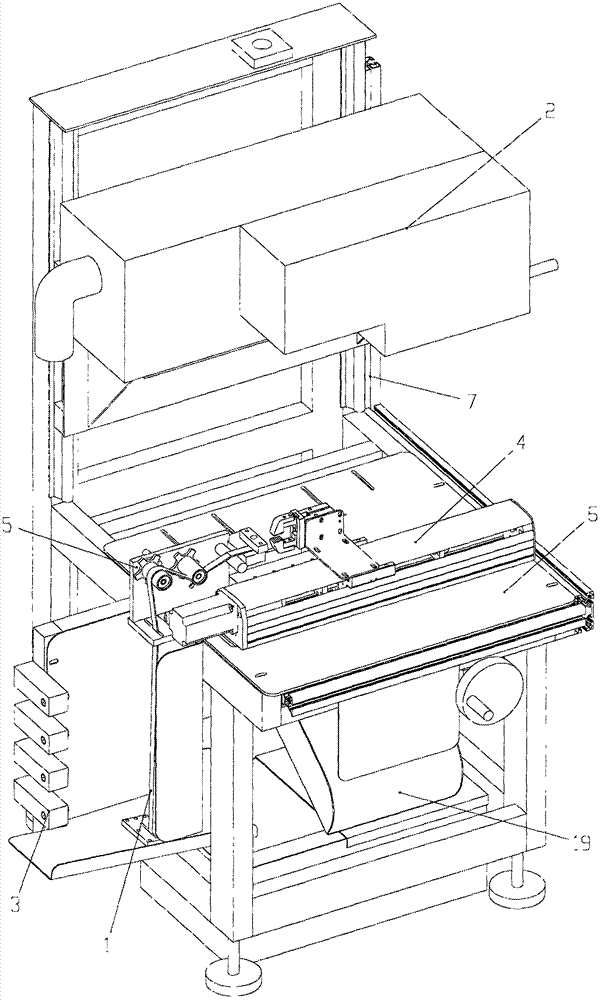

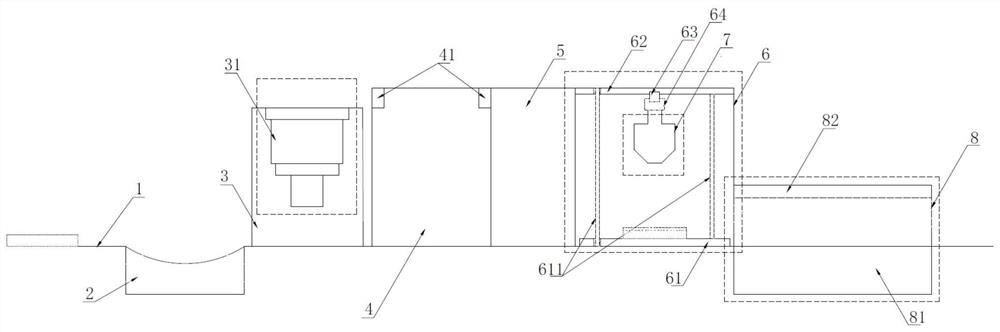

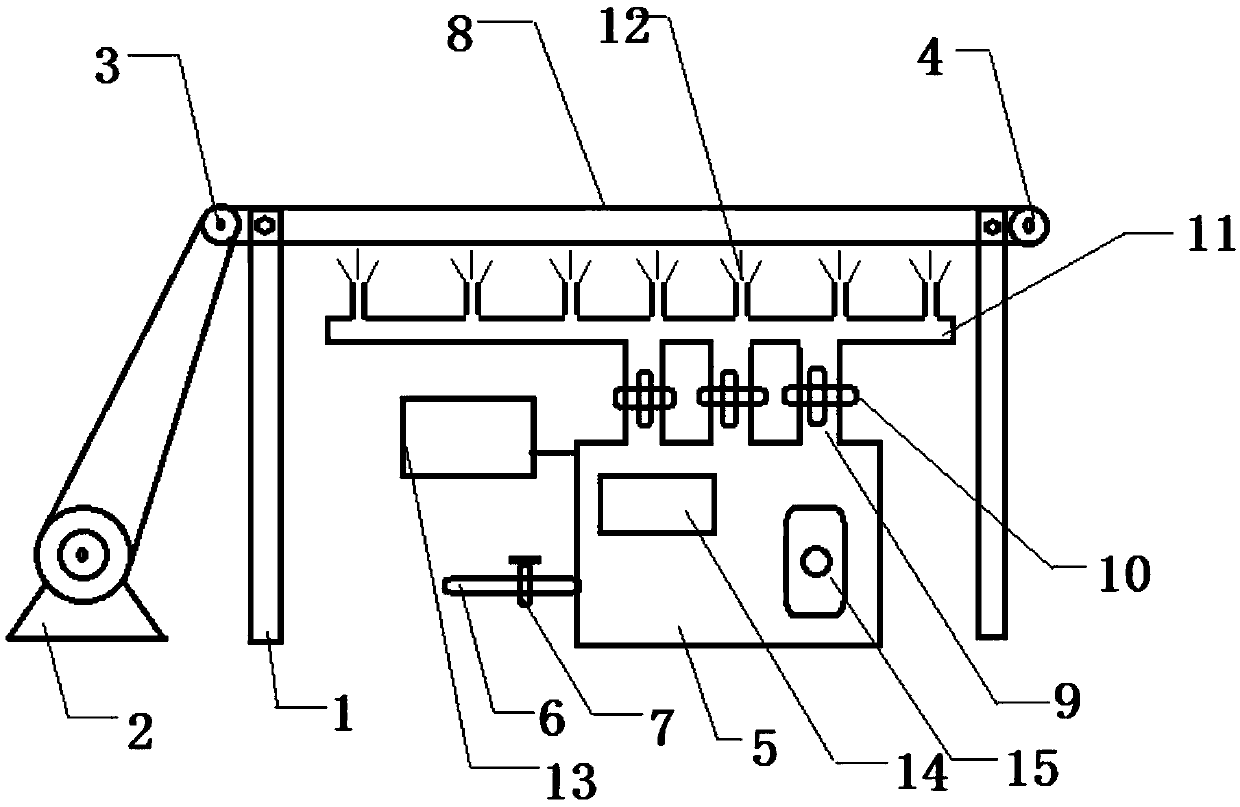

Fully automatic equipment for laser cutting of belt

ActiveCN106271112AIncrease productivityImprove product qualityWelding/soldering/cutting articlesMetal working apparatusLaser cuttingEngineering

The invention relates to automatic equipment, in particular to automatic equipment for laser cutting of a belt. The fully automatic equipment for the laser cutting of the belt comprises a laser device, a water spraying mechanism, a traction mechanism, a material conveying mechanism, a working table and a bracket, wherein the working table is fixedly connected to the bracket; the traction mechanism is fixedly connected to the working table; the material conveying mechanism is fixedly connected to the working table; the water spraying mechanism is fixedly connected to the bracket; the laser device is fixedly connected to the bracket; the laser device is located above the working table. Due to the cooperative operation of the water spraying mechanism, the traction mechanism and the material conveying mechanism, the operations such as stretching, cutting and material falling are repeatedly performed so as to fully automatically realize automatic laser cutting of the belt and control the laser cutting effect of the belt; and therefore, the production efficiency and the quality of a product are improved.

Owner:滁州辉煌无纺科技有限公司

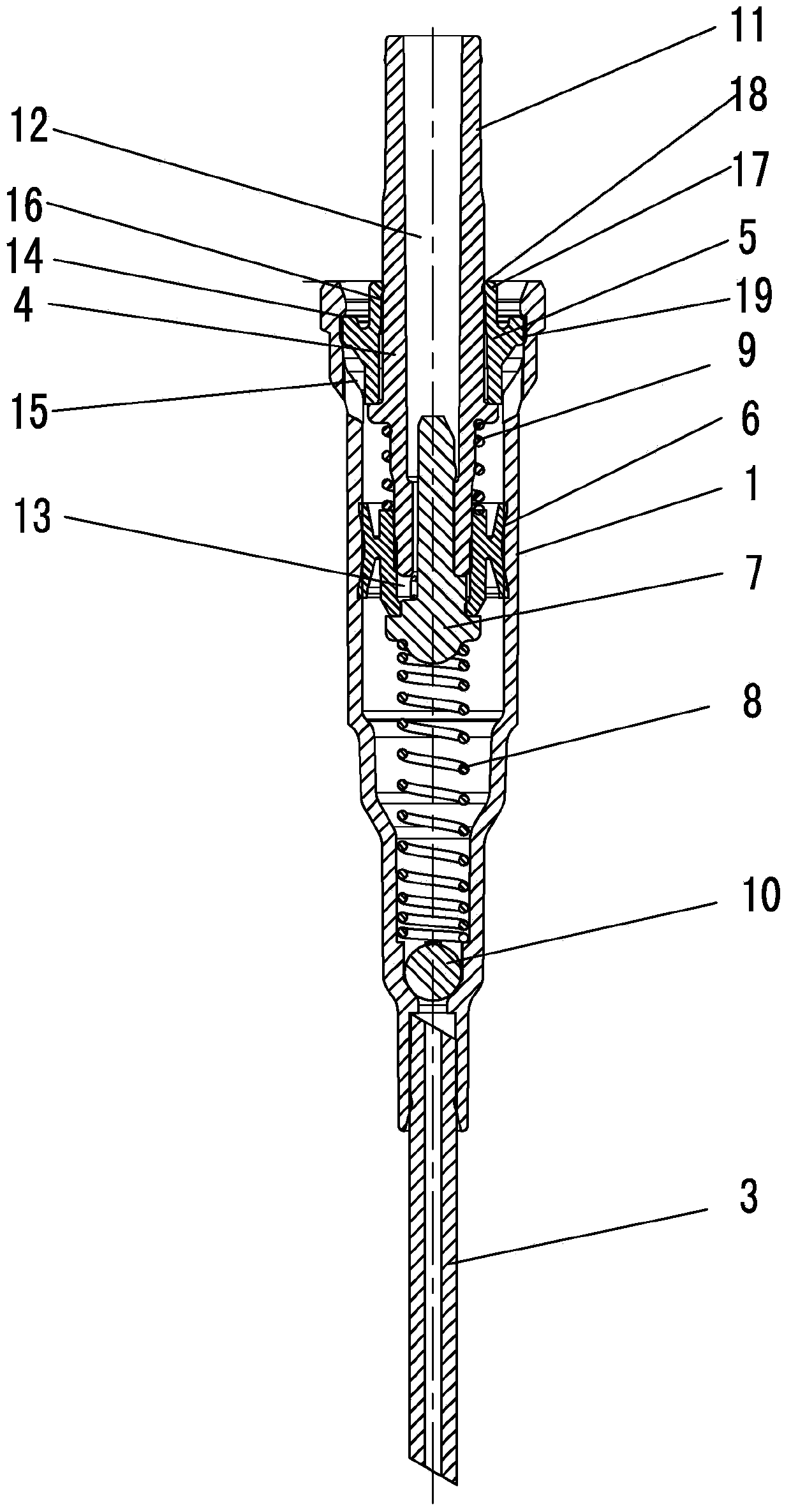

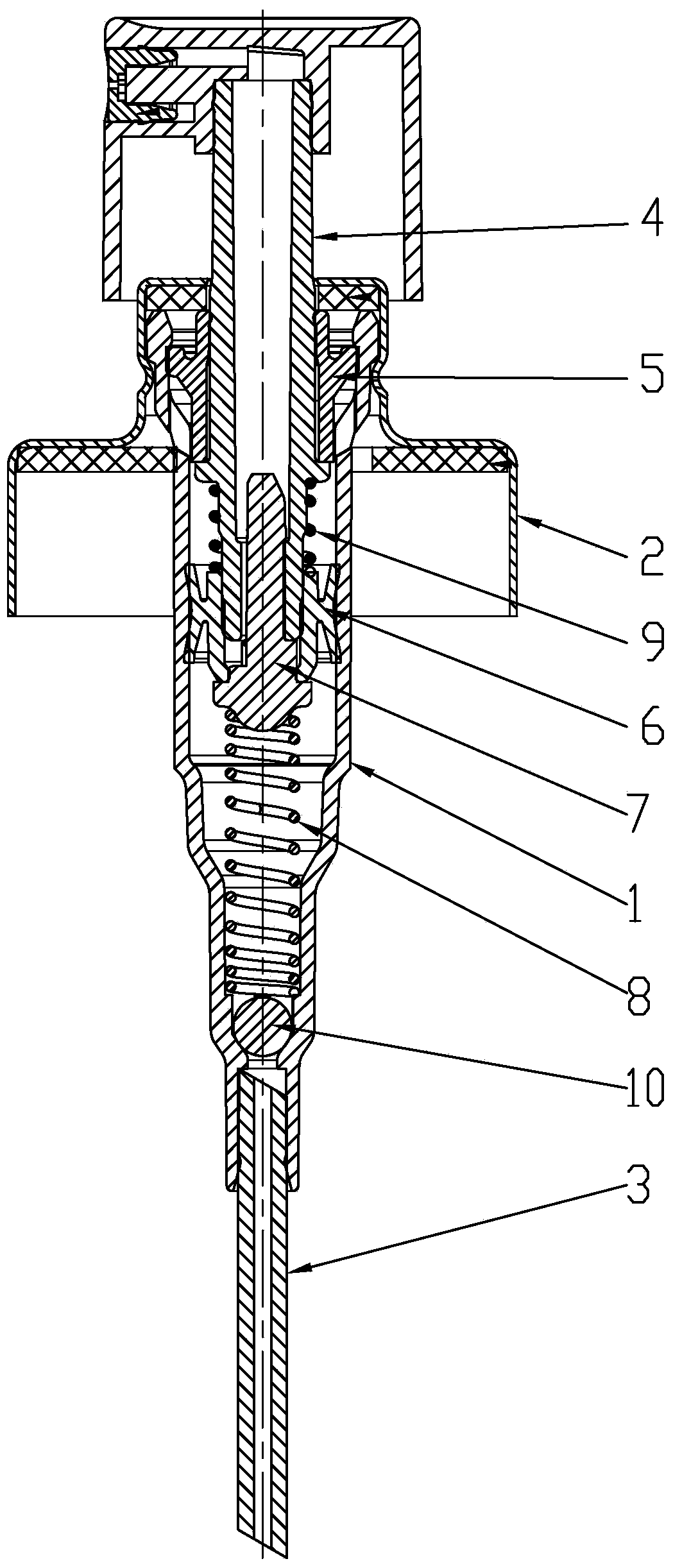

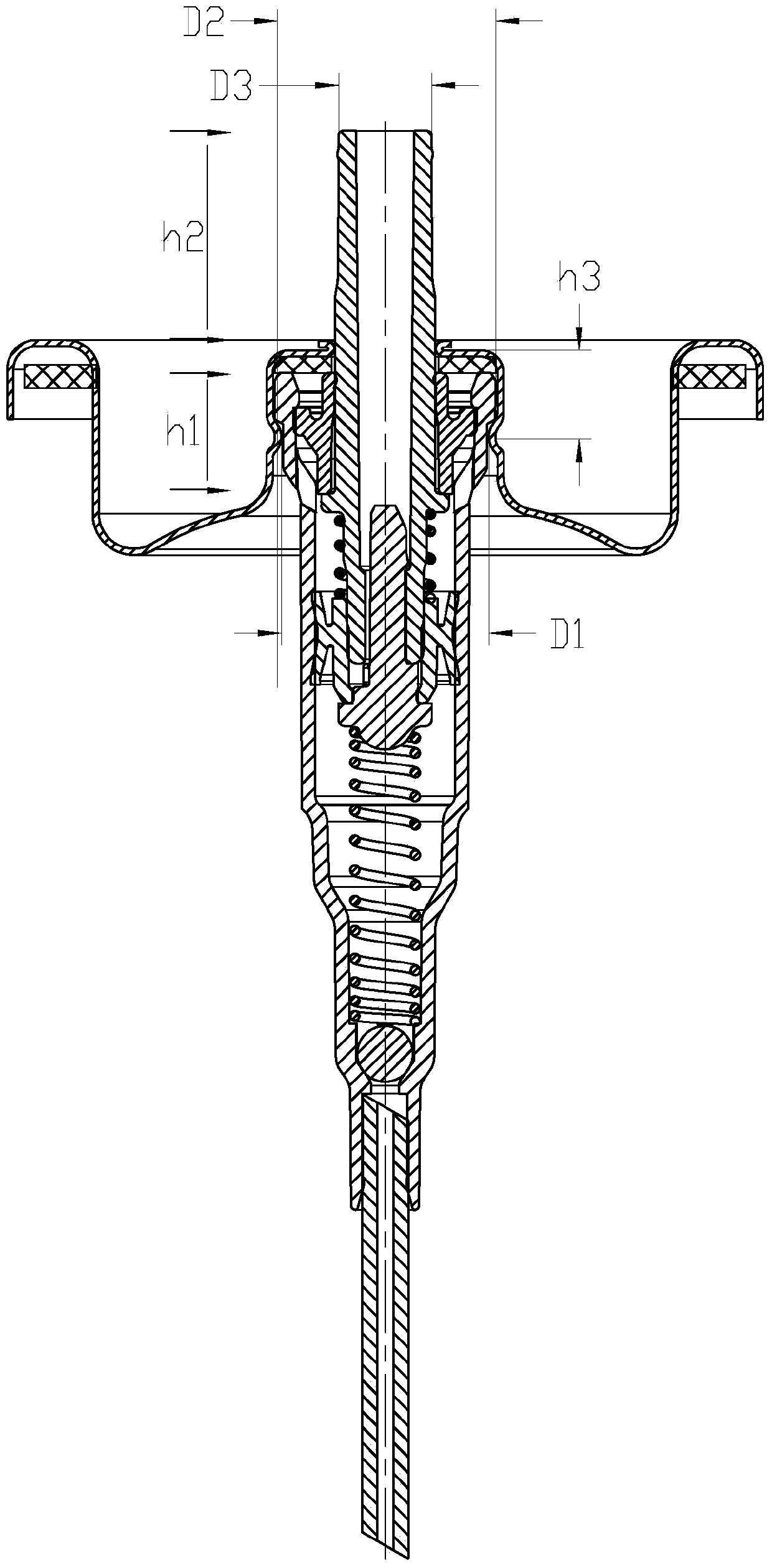

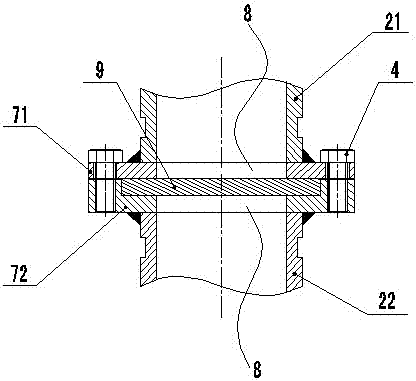

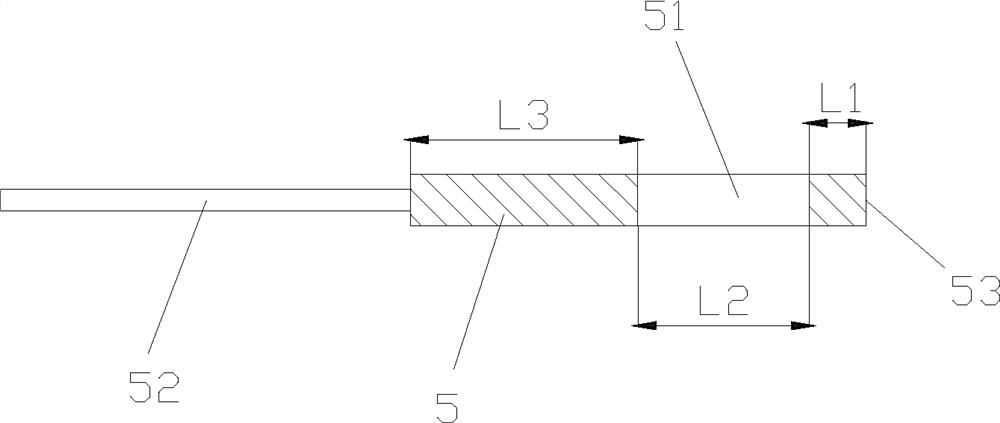

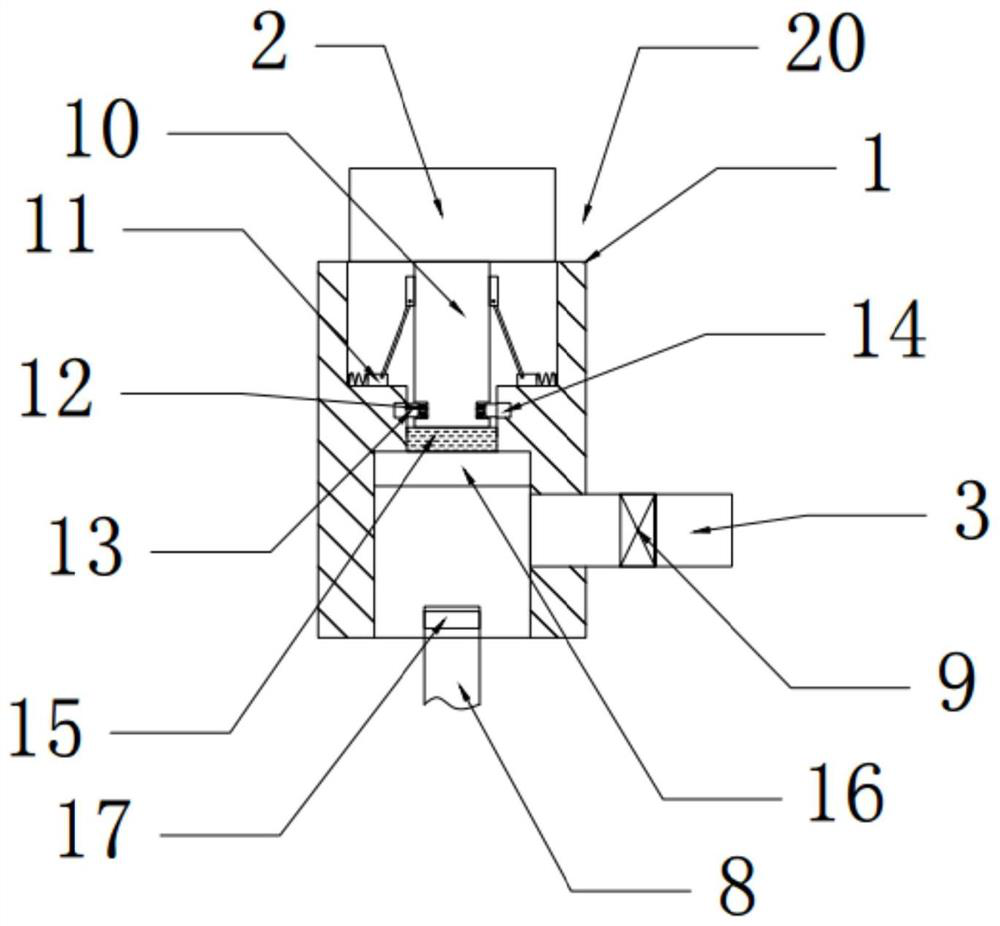

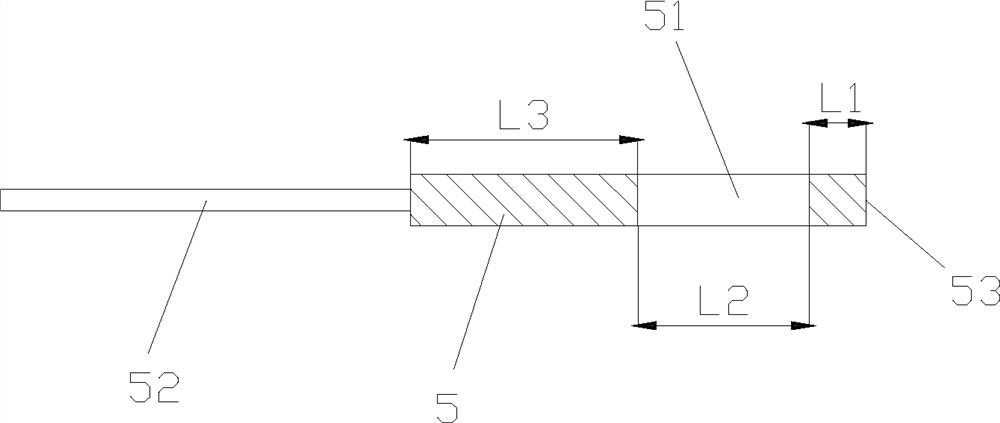

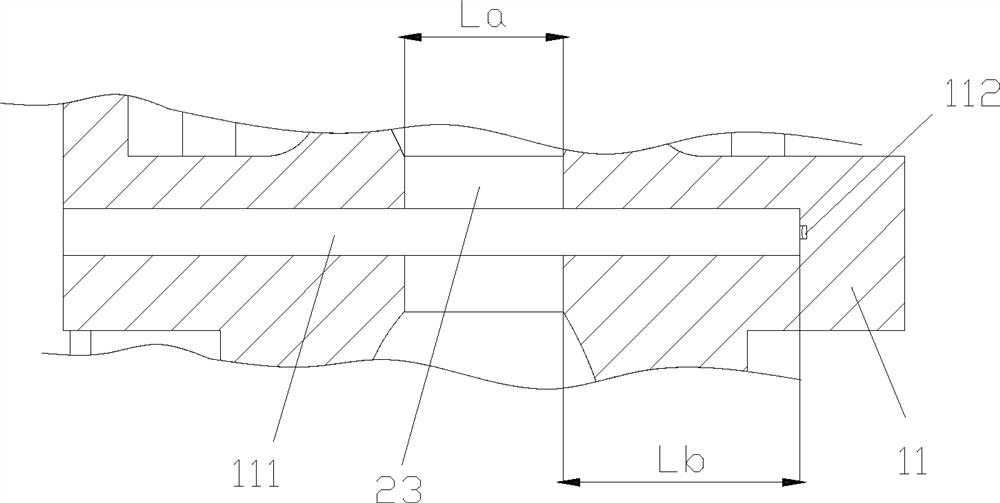

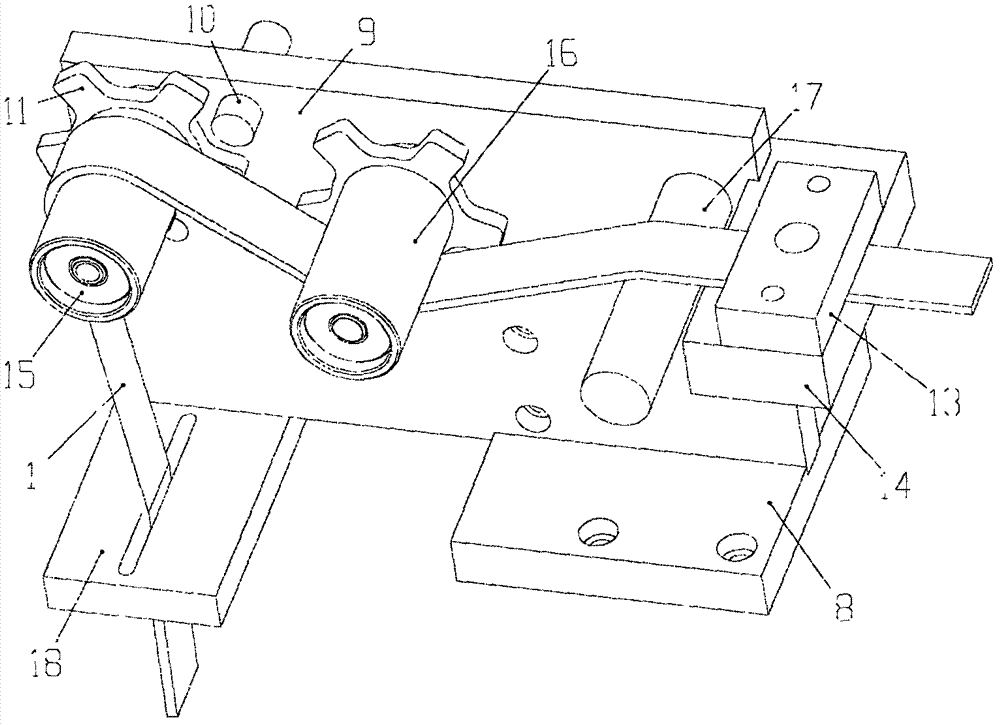

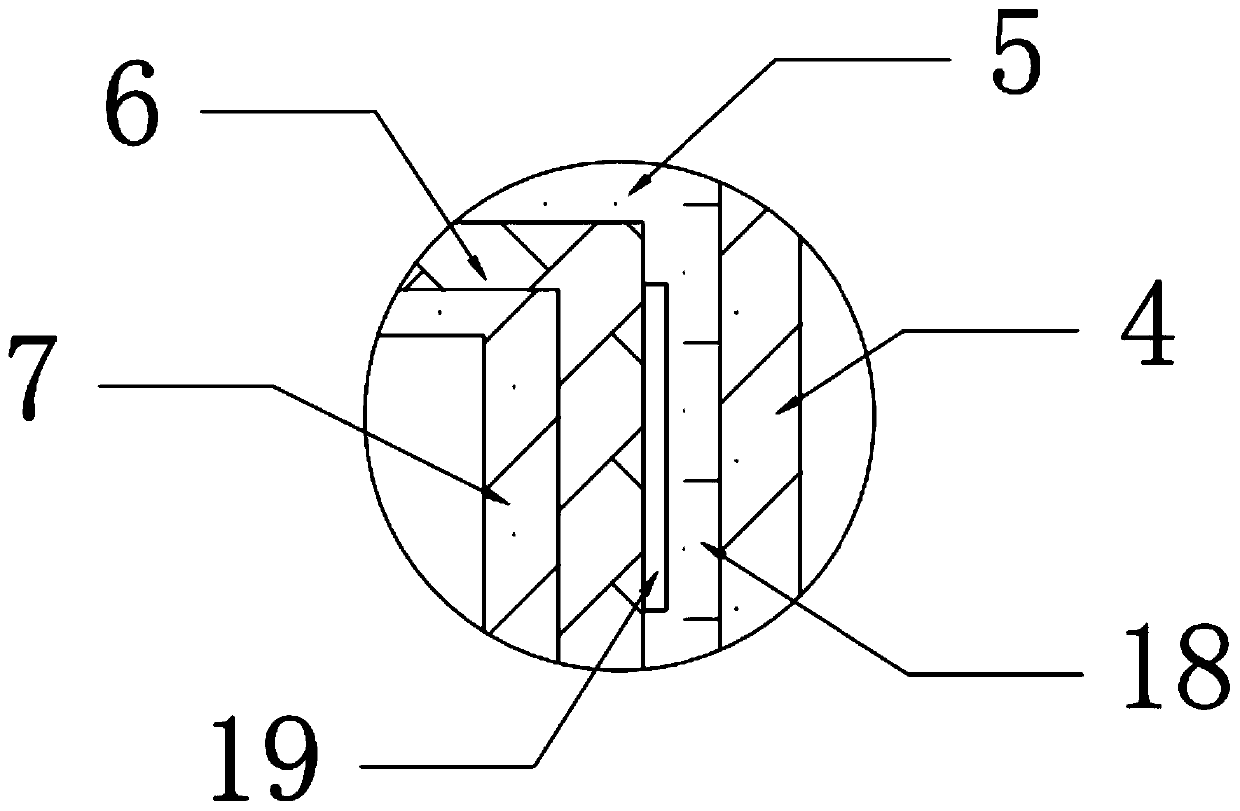

Series sprayer

InactiveCN103736612AControl the amount of ejectionSimple structureSingle-unit apparatusSprayerPump chamber

A series sprayer comprises a pump chamber. A seal cup is arranged at the position of a port at the upper end of the pump chamber, the lower end of the pump chamber is connected with a liquid drainage pipe, an upper pump rod, a locking cover, a piston, a lower pump rod, a main spring, an auxiliary spring and a pump bead are arranged in the pump chamber, the upper portion of the upper pump rod extends upwards from the inside of the pump chamber to form a connection section for fixing a button, a liquid extraction channel is arranged in the upper pump rod, the lower end of the upper pump rod is inserted into a plug from the lower pump rod, a gap for liquid to enter the liquid extraction channel is reserved, a piston sealing the gap is fixed between the upper pump rod and the lower pump rod, a main spring support is arranged at the bottom of the lower pump rod, and an auxiliary spring support is arranged between the piston and the upper pump rod. The sprayer has the advantage that the moving journey of the upper pump rod is controlled by means of locking cover height setting, so that the spraying quantity of the press nozzle can be controlled. Therefore, requirements of products of different series can be met by arranging different locking covers. The sprayer is simple in structure and favorable for reducing production cost.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

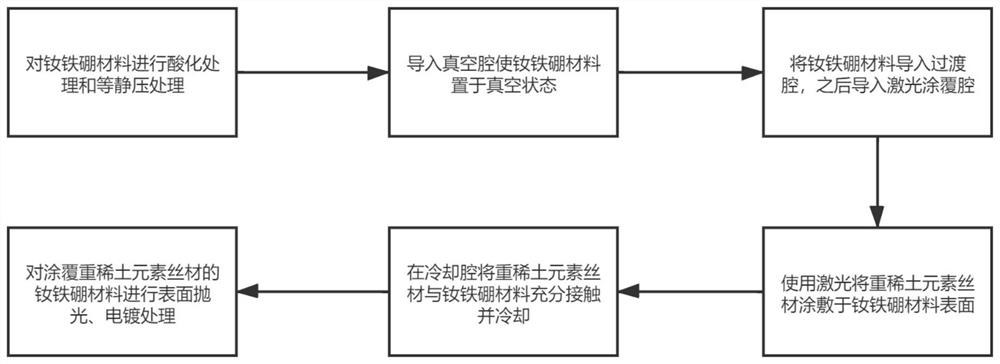

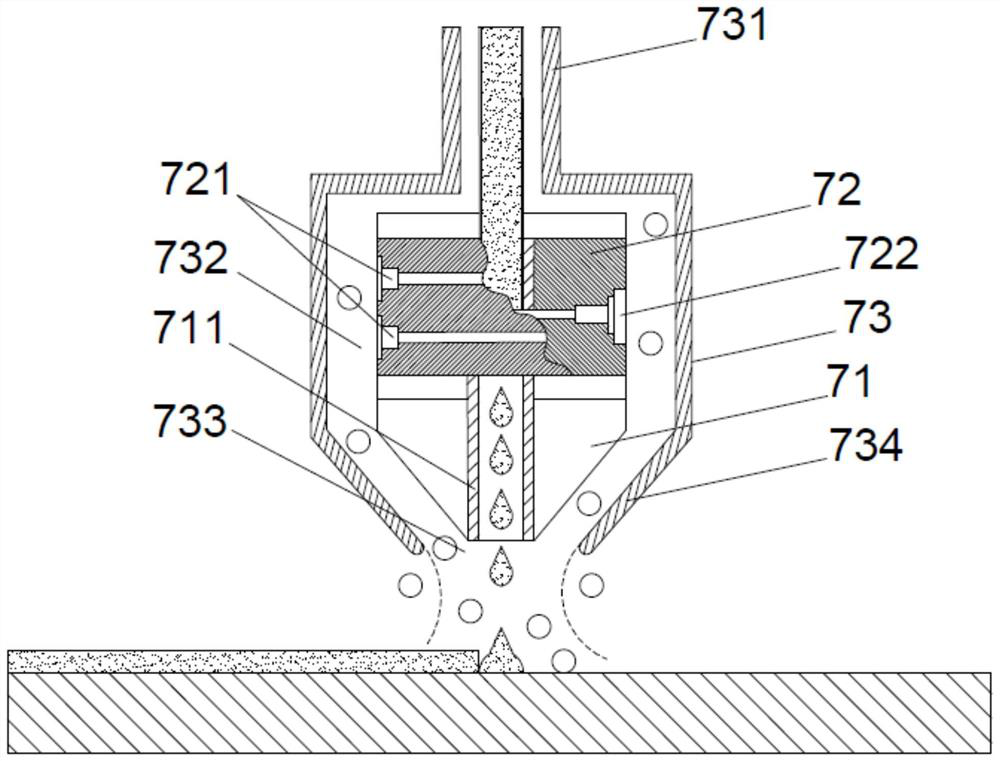

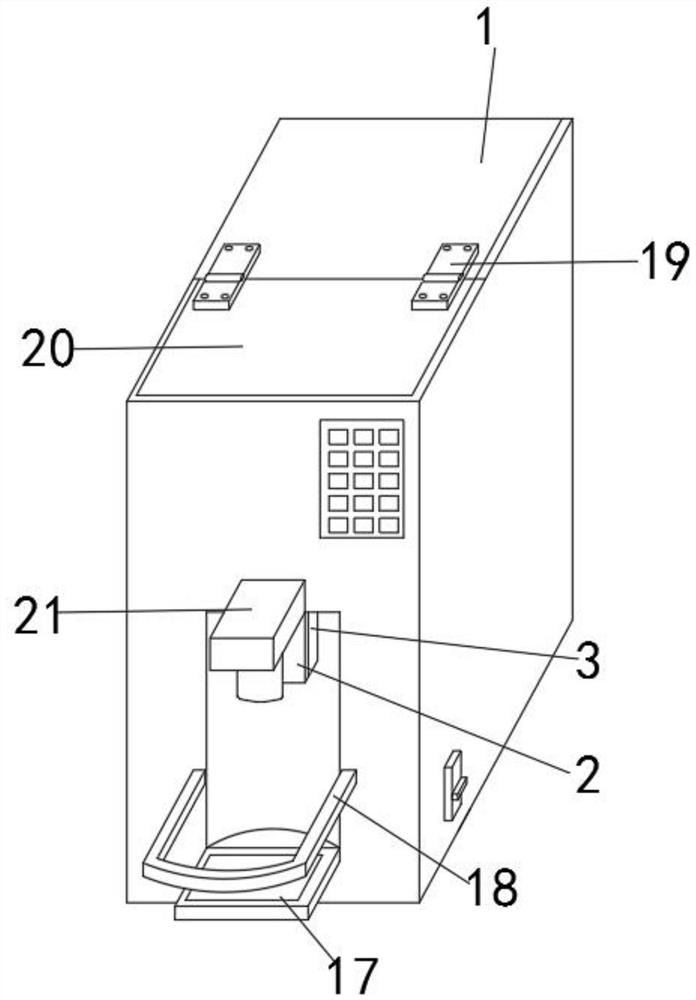

Method and equipment for laser cladding of heavy rare earth wire on surface of neodymium iron boron

ActiveCN112635188AEvenly distributedIncrease profitInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementLaser coating

The invention discloses a method and equipment for laser cladding of a heavy rare earth wire on the surface of neodymium iron boron, relates to the technical field of manufacturing of permanent magnet materials, and is mainly used for solving the problems that an existing method for coating the surface of a neodymium iron boron permanent magnet material with heavy rare earth elements is complex in process and uneven in distribution of the heavy rare earth elements. The method comprises the following steps of: S1, pretreating a neodymium iron boron permanent magnet material; S2, introducing the material into a vacuum chamber and a transition chamber; S3, guiding the treated material into a coating chamber, and coating a wire containing heavy rare earth elements by laser; and S4, performing cooling. The equipment structurally comprises a conveyor belt, and an acidification pool, an isostatic pressing chamber, a vacuum chamber, a transition chamber, a coating chamber and a cooling chamber which are sequentially arranged along the conveyor belt. According to the method and equipment for laser cladding of the heavy rare earth wire on the surface of the neodymium iron boron, the surface of the neodymium iron boron permanent magnet material can be uniformly coated with the heavy rare earth element by using a laser coating method, and meanwhile, the preparation process is also simplified.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Medical waste treatment device with disinfection and sterilization functions

InactiveCN112717188AExpand the spraying areaUniform disinfection effectLavatory sanitoryMedical waste disposalMedicineDisinfectant

The invention discloses a medical waste treatment device with disinfection and sterilization functions, which belongs to the technical field of medical waste treatment, and comprises a shell and a cover plate, the upper surface of the shell is provided with the cover plate, the upper side of the cover plate is provided with a top plate, the top plate is provided with a medicine spraying mechanism, and one end of the medicine spraying mechanism penetrates through the cover plate and extends into the shell; the lower surface of the medicine spraying mechanism is fixedly connected to the upper surface of the cover plate through a lifting mechanism. According to the device, the medicine spraying mechanism is arranged, a large amount of disinfectant is input into a coil pipe through the hard pipe, then the disinfectant is completely sprayed out through the spraying holes, at the moment, the coil pipe rotates to evenly throw out the disinfectant, the even spraying area of the disinfectant is enlarged, and the even spraying and disinfecting effects are improved; the lifting mechanism can be used for controlling the top plate to move up and down to adjust the position of the coil pipe, so that the coil pipe moves to different positions to achieve different spraying effects.

Owner:官秋茹

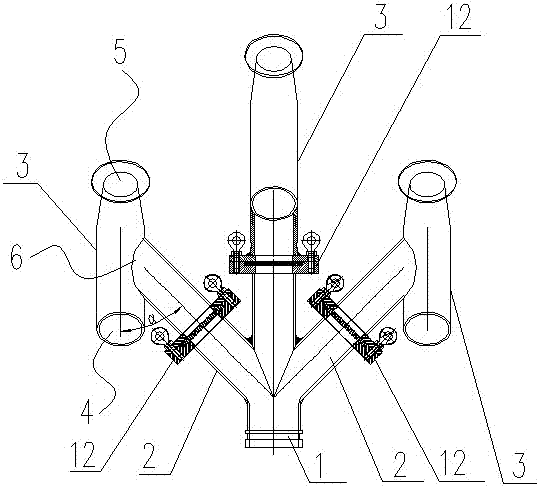

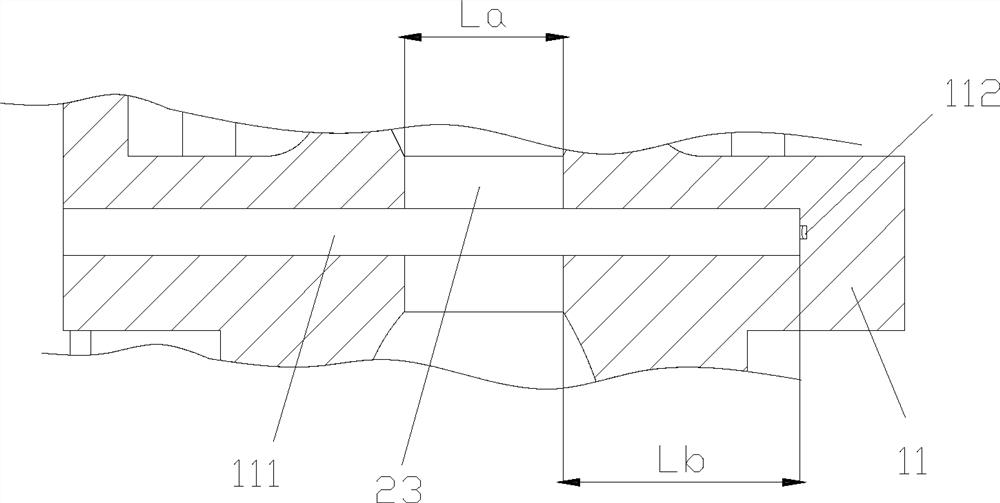

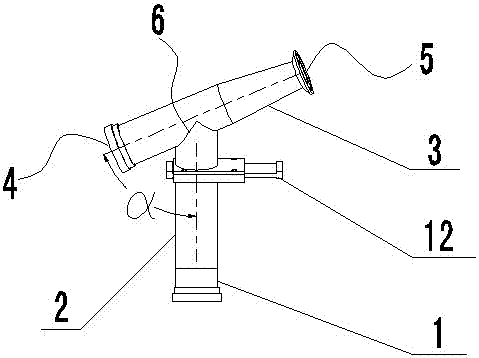

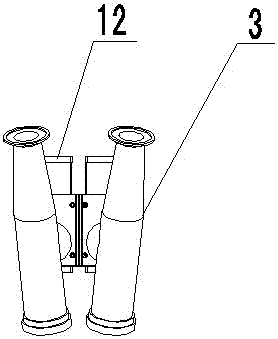

Multi-head discharging device of wet spraying machine

PendingCN107326908AFlexible switchingProduction of diverse needs to meetUnderground chambersFoundation engineeringMechanical engineeringMechanics

The invention discloses a multi-head discharging device of a wet spraying machine. The multi-head discharging device comprises a main pipe communicating with a concrete conveying pipeline, the main pipe is fixedly provided with at least three branch pipes communicating with the main pipe, an air-material mixer is arranged at the discharging end of each branch pipe, and the included angle alpha between the central axis of each air-material mixer and the central axis of the corresponding branch pipe. Each air-material mixer comprises an air inlet and a discharge outlet, wherein the air inlet and the discharge outlet are formed in the two ends of the air-material mixer in the axial direction correspondingly, a feed inlet is formed in the position, located between the air inlet and the discharge outlet, of the air-material mixer, and the feed inlet of the air-material mixer is connected with the discharging end of the corresponding branch pipe. Each branch pipe is provided with a flow adjusting structure. The air-material mixers can be freely and flexibly switched and the concrete spraying amount can be controlled according to the required amount of working hours and working conditions, and production diversification requirements of users are met.

Owner:河南省耿力工程设备有限公司

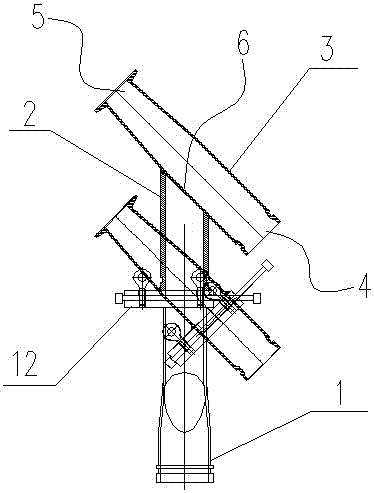

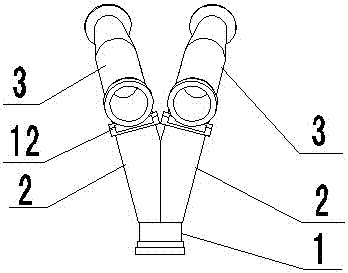

Wet spraying machine double-head discharging device

PendingCN107355235AFlexible switchingProduction of diverse needs to meetUnderground chambersFoundation engineeringControl engineeringMechanical engineering

The invention discloses a wet spraying machine double-head discharging device. The wet spraying machine double-head discharging device comprises a main pipe communicating with a concrete conveying pipeline. Two branch pipes communicating with the main pipe are fixedly arranged on the main pipe, the two branch pipes and the main pipe form a Y-shaped structure, air-material mixers are arranged at discharging ends of the branch pipes correspondingly, and the included angle alpha between the central axis of each air-material mixer and the central axis of the corresponding branch pipe is an acute angle; each air-material mixer comprises an air inlet and a discharging port which are formed in the two ends of each air-material mixer correspondingly in the axial direction, a feeding port is formed in the position, between the air inlet and the discharging port, of each air-material mixer, and the feeding port of each air-material mixer is connected with the discharging end of the corresponding branch pipe; and the two air-material mixers are distributed in a V shape, the discharging ports of the two air-material mixers are both located at one end of a flaring, and flow adjusting structures are arranged on the branch pipes correspondingly. According to the wet spraying machine double-head discharging device, the air-material mixers can be freely and flexibly switched to control the concrete spraying amount according to the demand quantity of man-hours and working conditions, and the requirement for diversified production of users is met.

Owner:河南省耿力工程设备有限公司

An automatic ground disinfection robot for medical departments

ActiveCN113842482BApply evenlyDo not polluteAutomatic obstacle detectionTravelling automatic controlMedical equipmentMedical department

The invention relates to the technical field of medical equipment, in particular to a ground automatic disinfection robot for medical departments, including a walking device, an alarm device and a disinfection device. The walking device is a disc-shaped robot, and the walking devices are installed sequentially from bottom to top The sterilizing device includes: a uniform sterilizing component and a baffle plate, and the uniform sterilizing component includes a liquid supply mechanism, a liquid spray mechanism and a blower fan. The cooperation between the devices realizes the automatic and comprehensive disinfection of the floor of the medical department. The obstructions are blocked by the baffles, so that the obstructions will not be contaminated with the disinfectant, and the disinfection work of the disinfectant only on the ground is realized. And the uniform application of the disinfectant by the blower fan realizes the comprehensive disinfection of the ground and ensures the uniform application of the disinfectant.

Owner:SOUTHWEST JIAOTONG UNIV +1

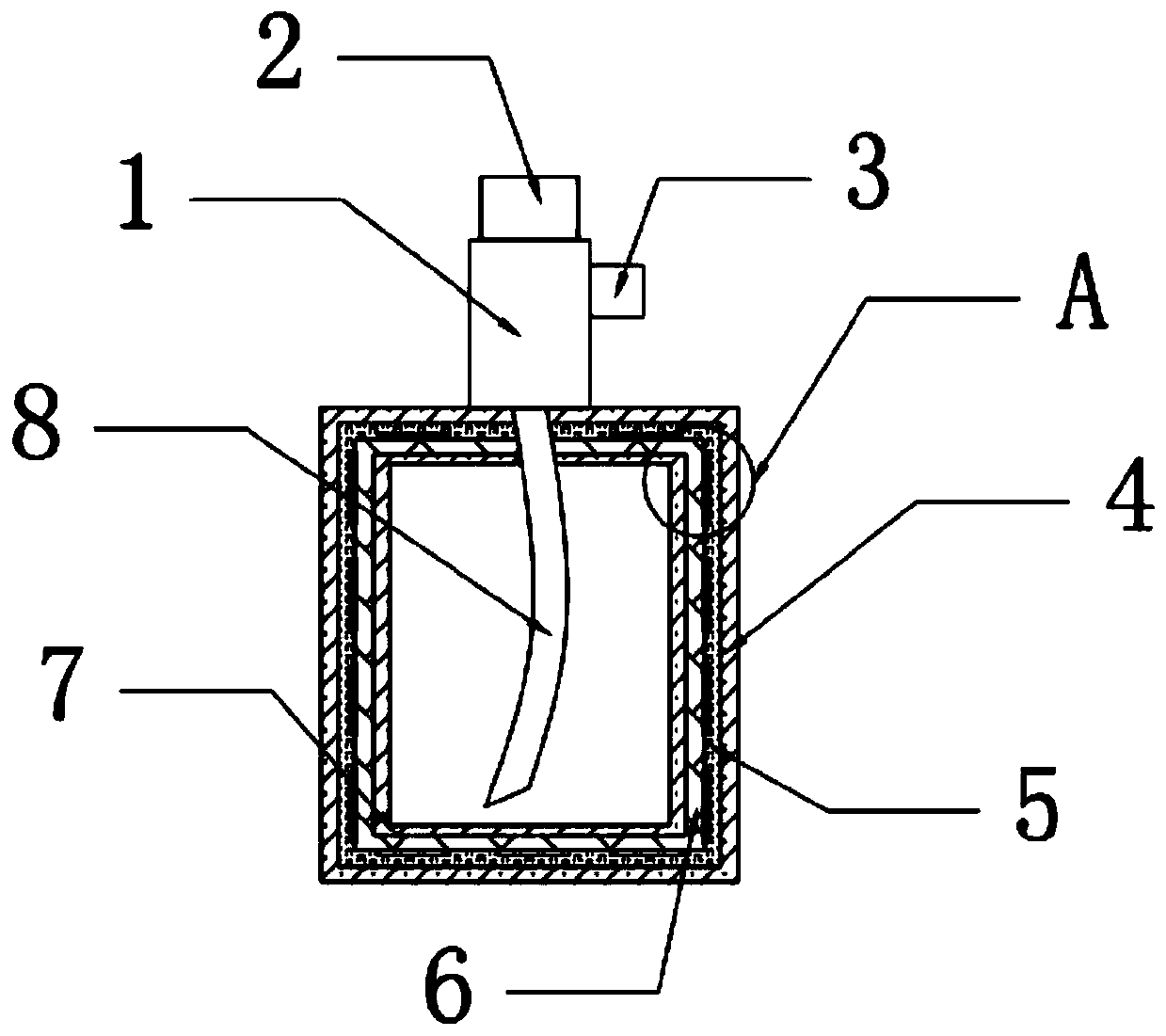

A push-type temperature-sensitive color-changing perfume bottle

ActiveCN109850371BPrevent volatilizationAvoid wastingDomestic cooling apparatusClosuresPolymer scienceInsulation layer

The present invention relates to the technical field of perfume bottles, in particular to a push-type temperature-sensitive color-changing perfume bottle, which includes a first glass layer, a color-changing layer and a pressing device. The top of the first glass layer is provided with a pressing device, and the bottom of the pressing device is provided with There is a water outlet pipe, the water outlet pipe extends into the perfume bottle, a discoloration layer is arranged inside the first glass layer, a heat insulation layer is arranged inside the discoloration layer, and a second glass layer is arranged inside the heat insulation layer , the present invention can prevent the volatilization of the perfume in the perfume bottle by setting the heat insulation layer. By setting the flow controller, the spray volume of the perfume can be effectively controlled and unnecessary waste is reduced. By setting the discoloration layer, the perfume bottle It has the function of changing color, which makes the perfume bottle look more dazzling under the light, which is beneficial to improve the attention of the perfume bottle.

Owner:陆杭峰

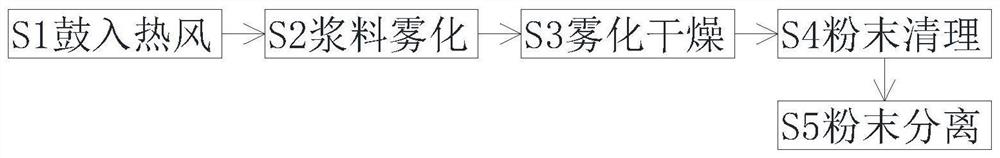

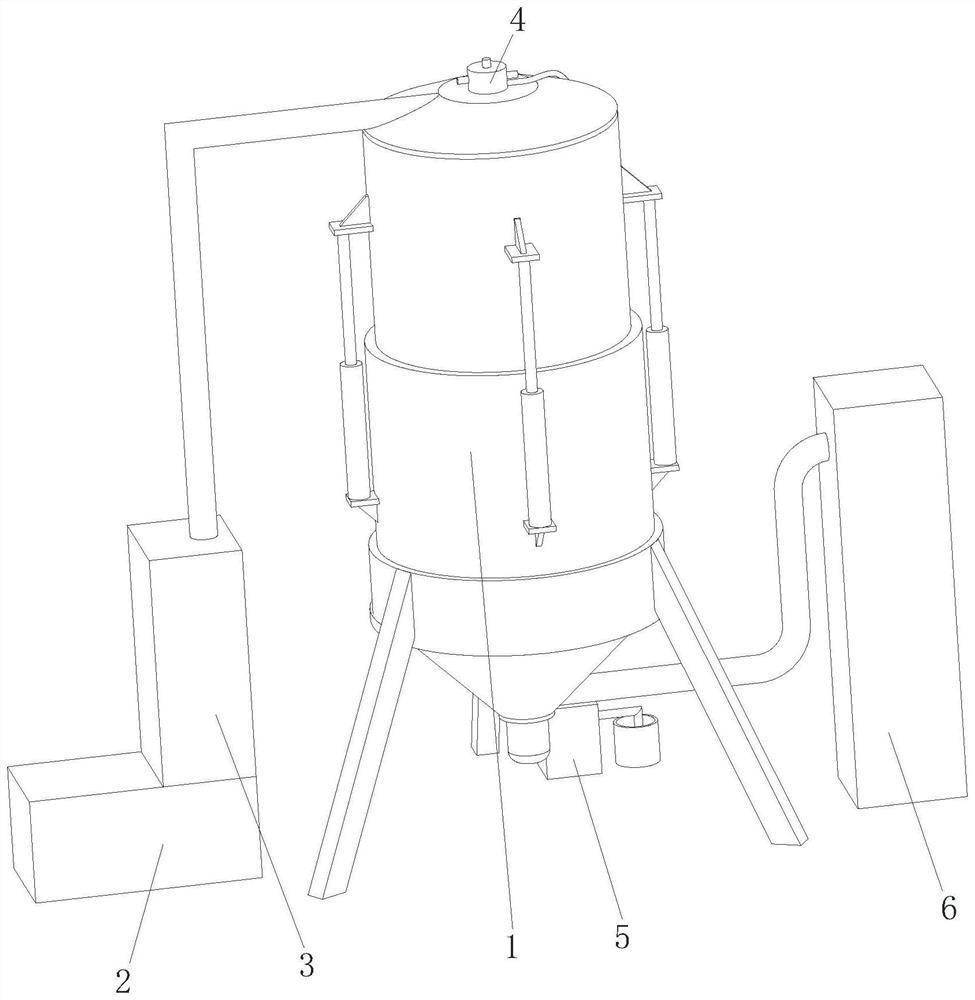

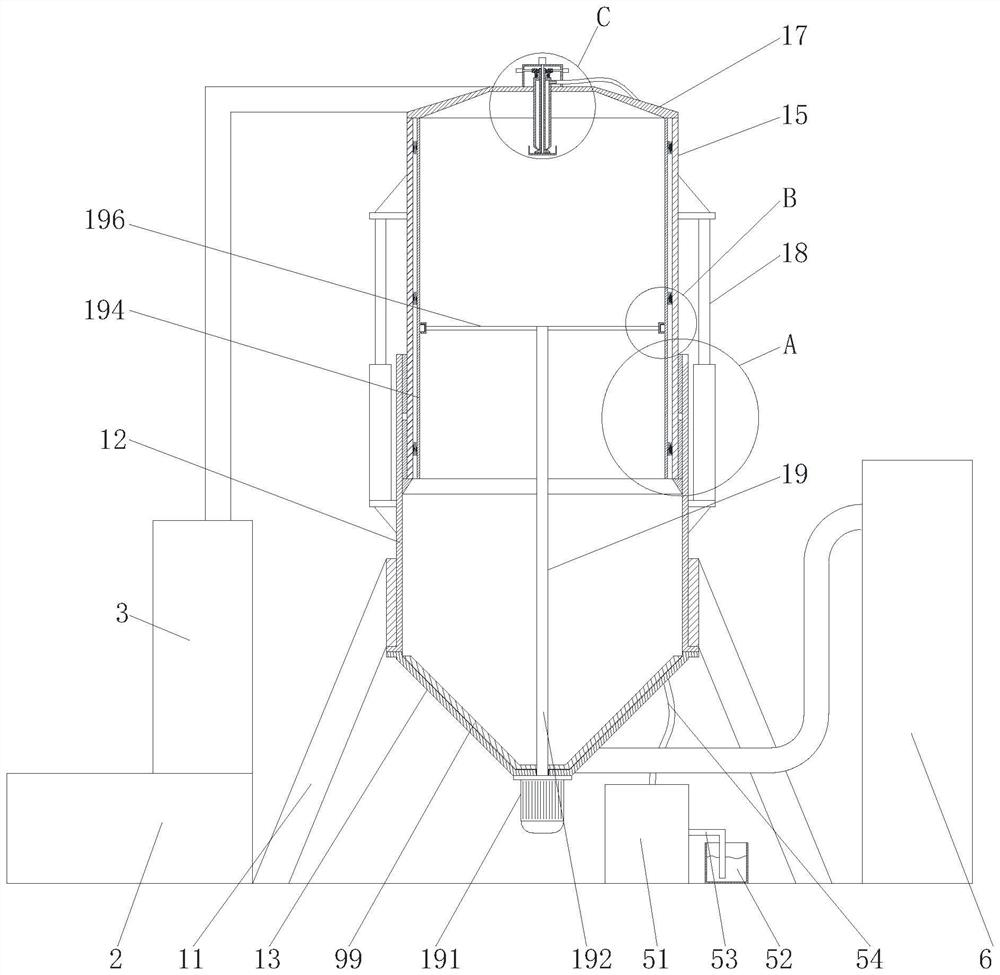

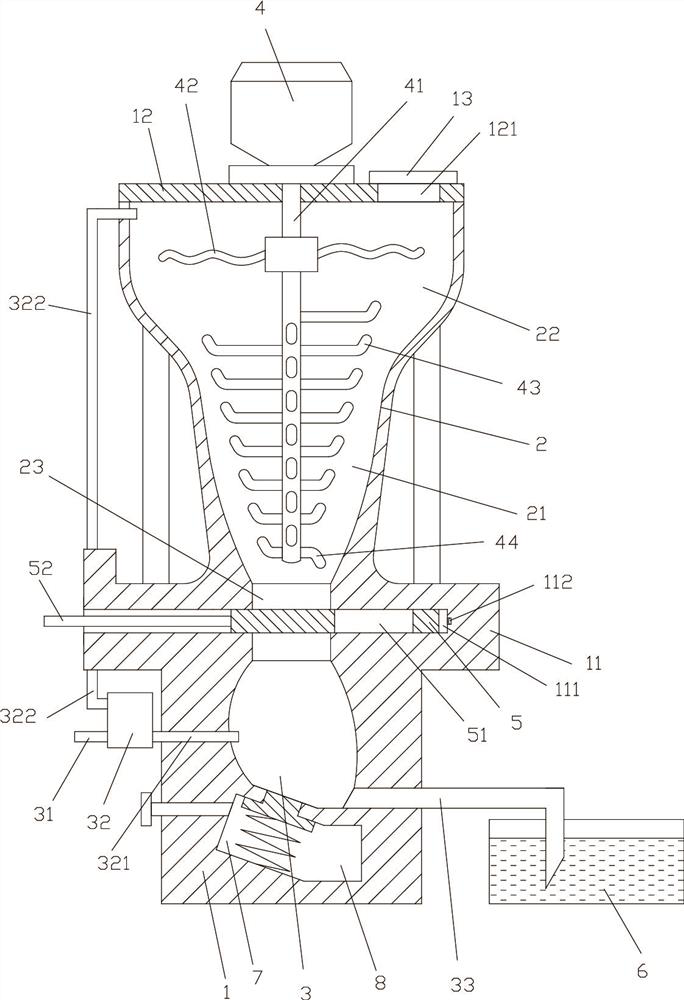

Spray drying method for preparing modified light calcium carbonate

InactiveCN113082746AAvoid affecting productionExpand the scope of workCalcium/strontium/barium carbonatesEvaporator accessoriesPhysical chemistrySpray dried

The invention relates to a spray drying method for preparing modified light calcium carbonate; spray drying equipment is used for preparing modified light calcium carbonate, and the spray drying equipment for preparing modified light calcium carbonate comprises a drying tower, an air blower, an electric heating machine, an atomizing device, a feeding device and a separating device. When the spray drying equipment for preparing the modified light calcium carbonate is used for performing spray drying on the modified light calcium carbonate, the spray drying method comprises the following steps: S1, blowing in hot air; S2, atomizing the slurry; S3, carrying out spray drying; S4, cleaning powder; and S5, carrying out powder separation. The spray drying time can be controlled, so that the spray drying equipment works according to different requirements, the working range is expanded, and the situation that powder adheres to the interior of equipment and influences production can be prevented.

Owner:合肥高尧化工科技有限公司

Powder spraying device capable of achieving pressure relief and accurately controlling spraying amount

The invention discloses a powder spraying device capable of achieving pressure relief and accurately controlling the spraying amount. The powder spraying device comprises a machine base. A dividing part is arranged in the middle of the machine base, and the interior of the machine base is divided into a stock bin and a mixing bin. A blanking opening is formed in the dividing part and is connectedwith the stock bin and the mixing bin. An inserting groove is formed in the dividing part in the horizontal direction, a sliding quantitative baffle is arranged in the inserting groove, and a quantitative opening is formed in the sliding quantitative baffle. A pull rod is arranged at the tail end of the sliding quantitative baffle, a high-pressure air inlet pipe is arranged on the side edge of themixing bin and connected with an air distributing part, and the air distributing part is provided with an air spraying pipe and a constant-pressure pipe. The air spraying pipe is inserted into the mixing bin, and the constant-pressure pipe is connected with the top of the stock bin. A molten aluminum pool is formed in the side edge of the mixing bin, the mixing bin is provided with an extending graphite pipe, and the graphite pipe is inserted into the molten aluminum pool. The spraying amount of a refining agent can be rapidly and accurately controlled, it is guaranteed that the concentrationof a sprayed gas-powder mixture is continuous and stable, and the conveying of the refining agent can be suspended when a spray rod is blocked.

Owner:严维燕

Metal rubber-based multifunctional cleaner

PendingCN108421736AReduce weightEasy to carrySpraying apparatusCleaning using toolsMetal rubberHand held

The invention provides a metal rubber-based multifunctional cleaner, which comprises a shell as well as a scrubbing module, a liquid spraying module and a control module which are arranged on the shell, wherein the tail of the shell is provided with a hand-held rod, and the head of the shell is provided with the scrubbing module; the scrubbing module comprises a brushing disc and a brushing disc motor, and the liquid spraying module is adjacent to the scrubbing module; the liquid spraying module comprises an atomizing spraying mechanism, a liquid storage mechanism and a sensor, and the atomizing spraying mechanism is connected with the liquid storage mechanism and the spraying direction thereof faces the surface to be cleaned; the working mode of the liquid spraying module comprises a manual mode and an automatic mode; when the working mode of the liquid spraying module is the automatic mode, a liquid outlet of the atomizing spraying mechanism is monitored by the sensor, if the liquidoutlet is close to the surface to be cleaned, the atomizing spraying mechanism is started by the sensor to spray a mist cleaning liquid to the surface to be cleaned; the product is light in weight, convenient to carry, and is not easy to destroy the surface appearance of a wall body when in work.

Owner:FUZHOU UNIV

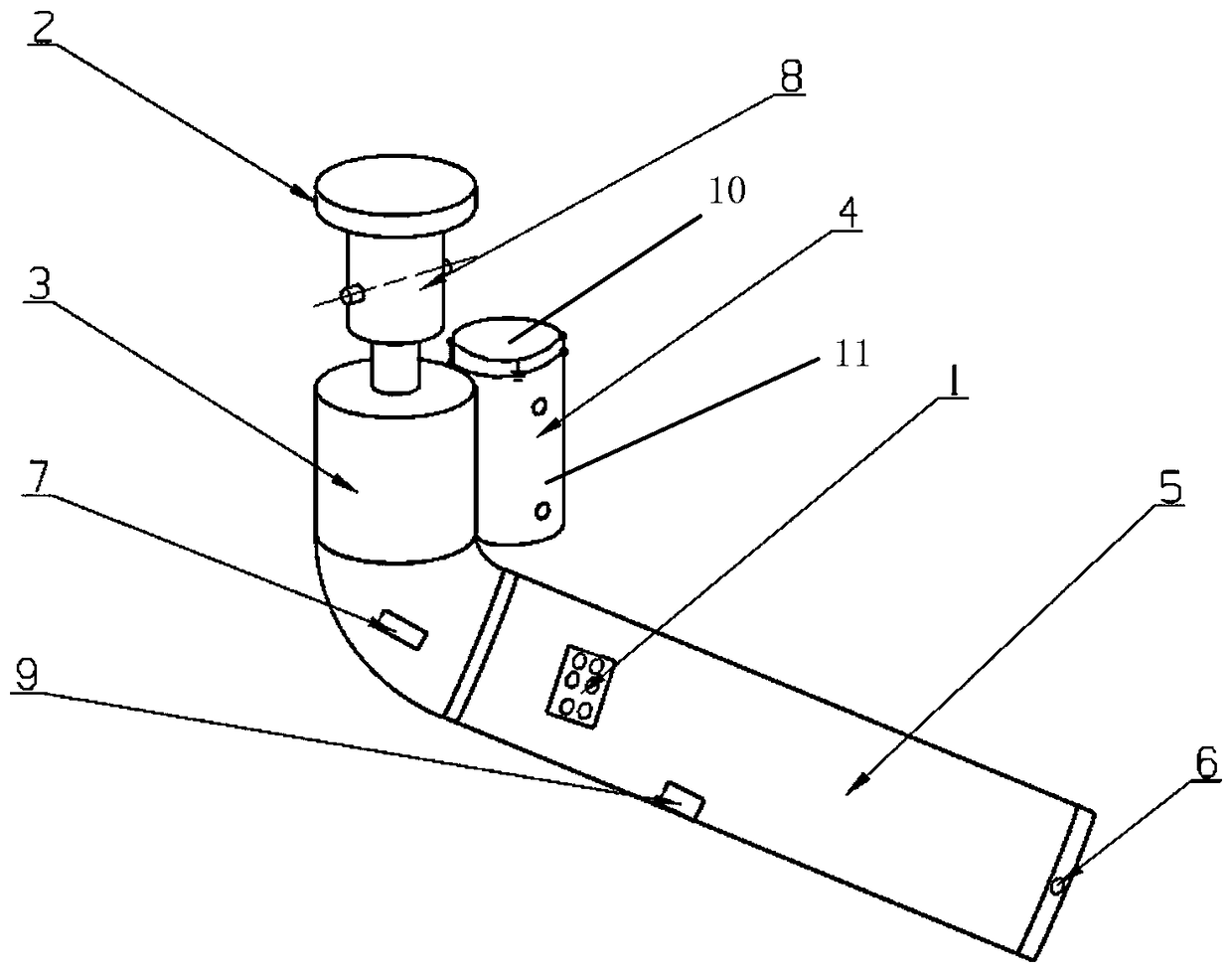

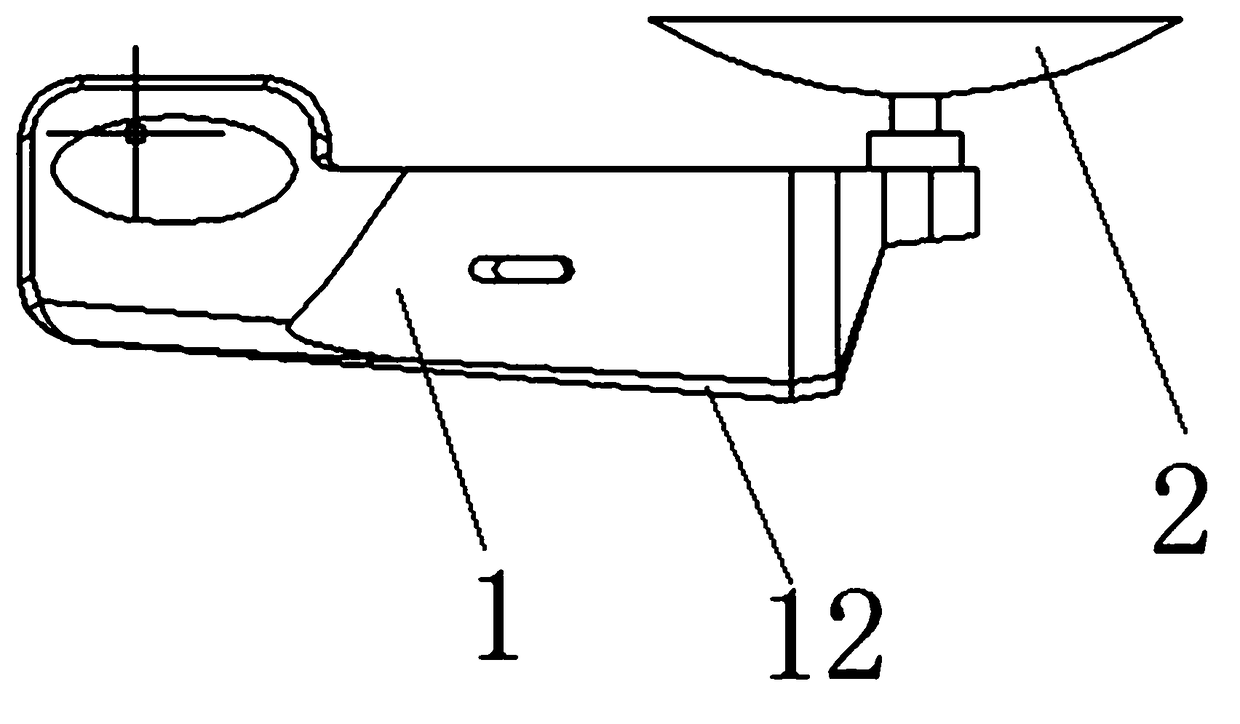

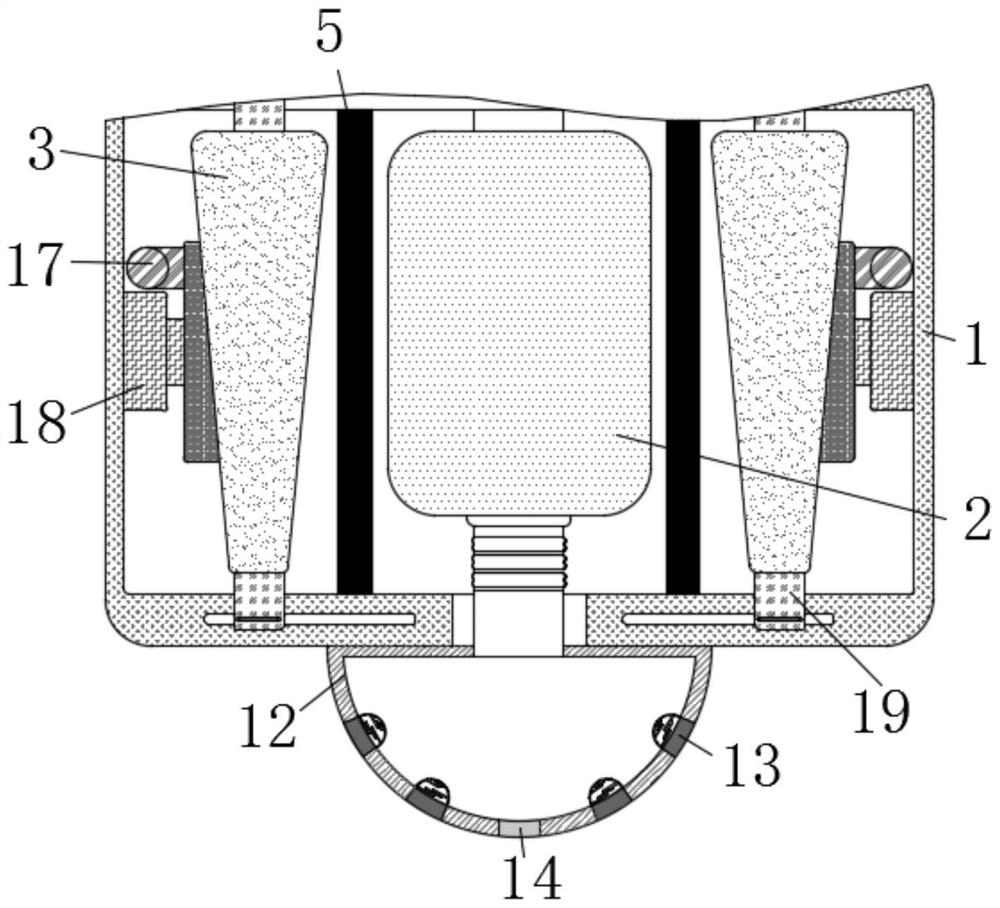

Handheld accurate and quantitative paint make-up device for railway component maintenance

InactiveCN112871492AImprove convenienceAccurate ejection volumeSingle-unit apparatusStructural engineeringLower face

The invention provides a handheld accurate and quantitative paint make-up device for railway component maintenance, and belongs to the technical field of railway component handheld paint make-up devices. The handheld accurate and quantitative paint make-up device comprises a shell, center bags are arranged in the shell, conical rollers corresponding to the center bags are evenly connected to the interior of the shell in a sliding manner, and limiting layers are arranged between the center bags and the conical rollers; and the upper faces and the lower faces of the center bags are both connected with adjusting discs, fixed discs are movably connected between the adjusting discs and the shell, and adjusting belts are connected between the adjusting discs. According to the handheld accurate and quantitative paint make-up device for railway component maintenance, adjusting rings are used for driving the conical rollers on the adjusting rings through telescopic rods, and the combined effect of the center bags, a conversion chamber, the adjusting belts and the adjusting discs is combined, so that the paint spraying-out amount can be more accurately controlled, the paint make-up accuracy, convenience and quality of railway components are greatly improved, and meanwhile, the paint make-up aesthetic degree and the functionality of other required characteristics are correspondingly improved.

Owner:王珍伟

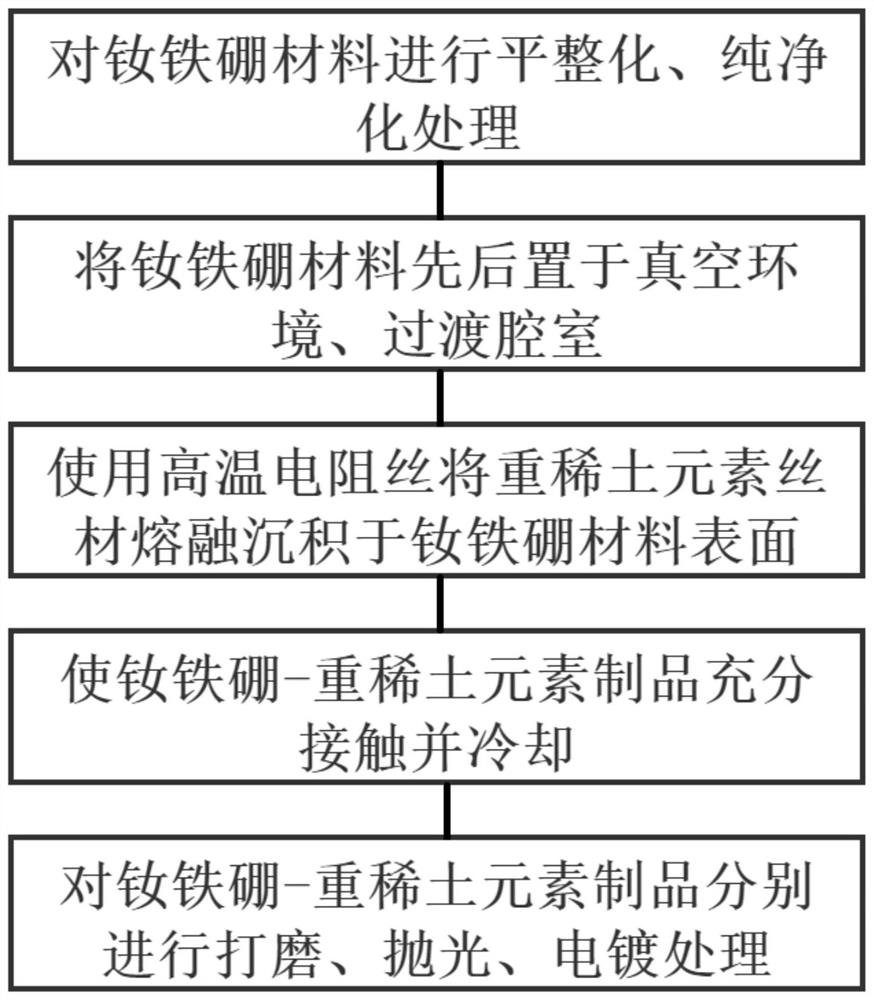

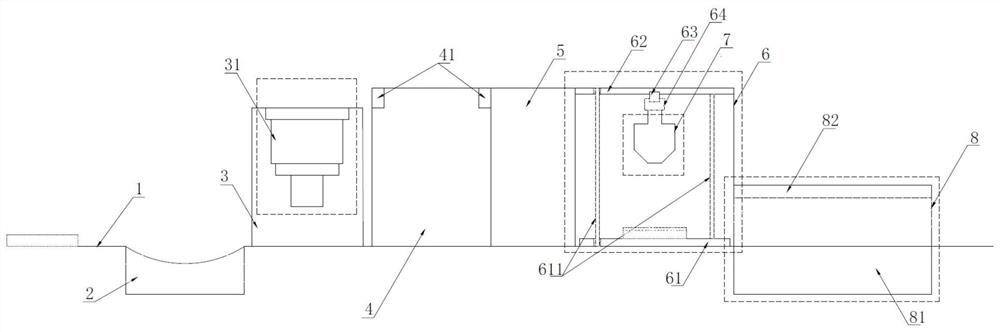

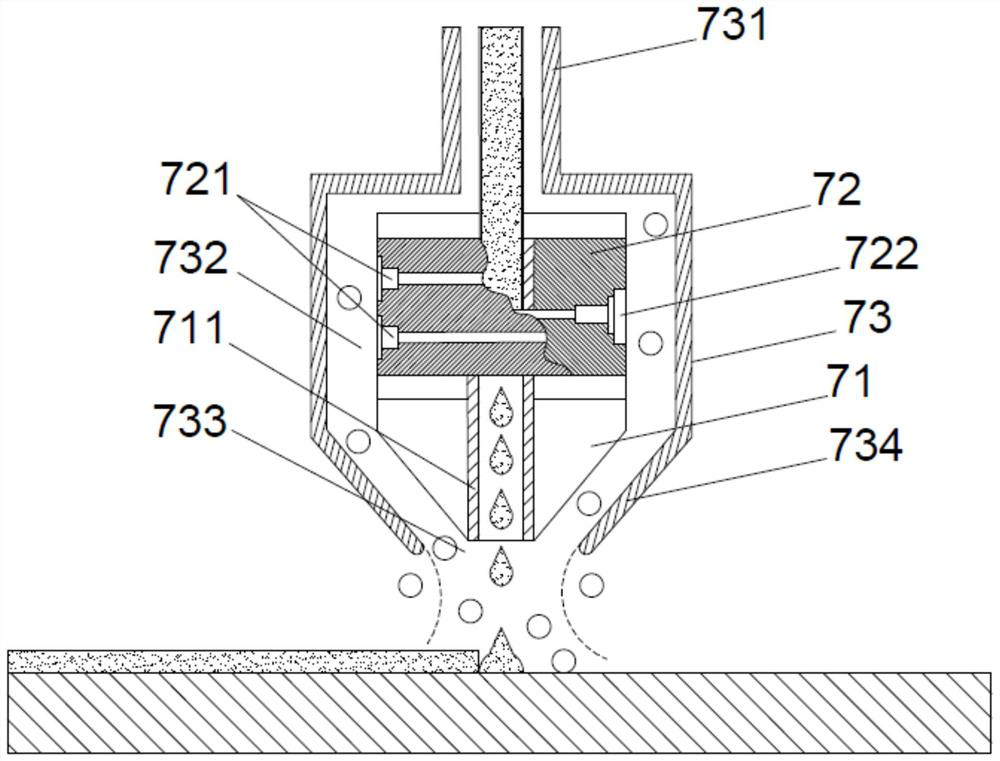

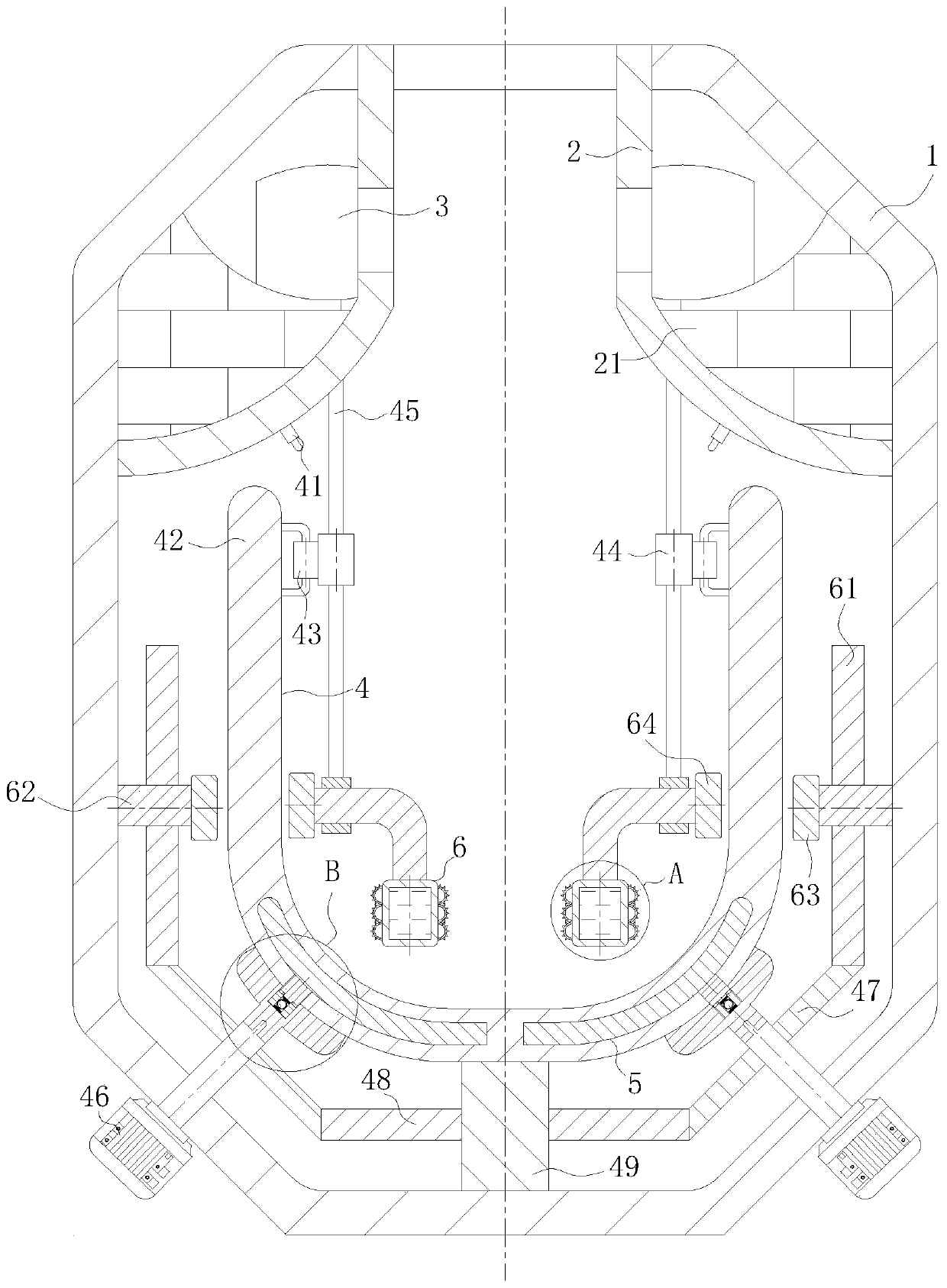

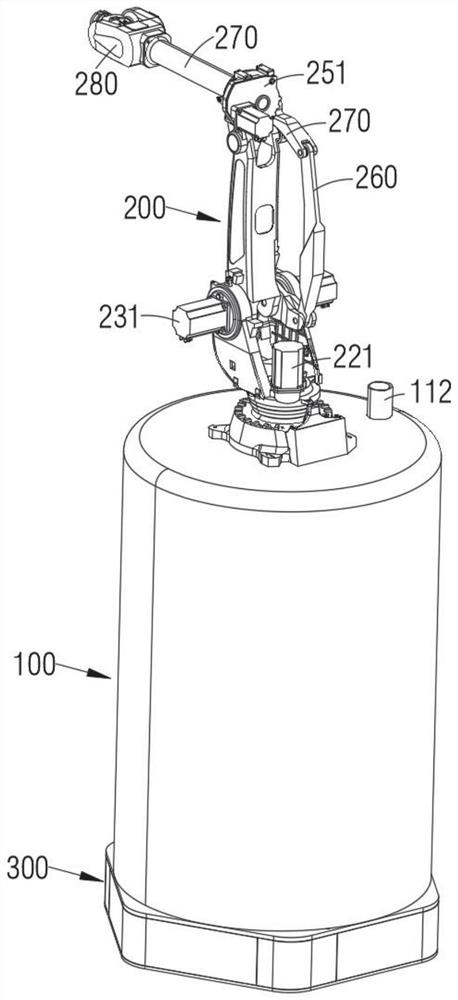

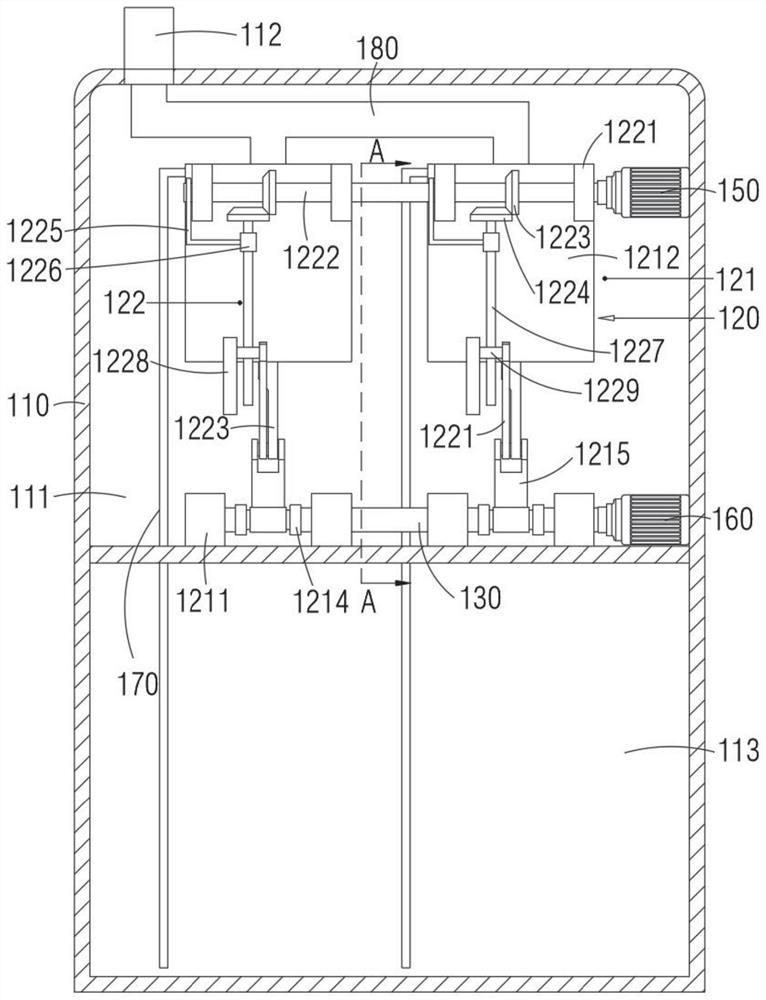

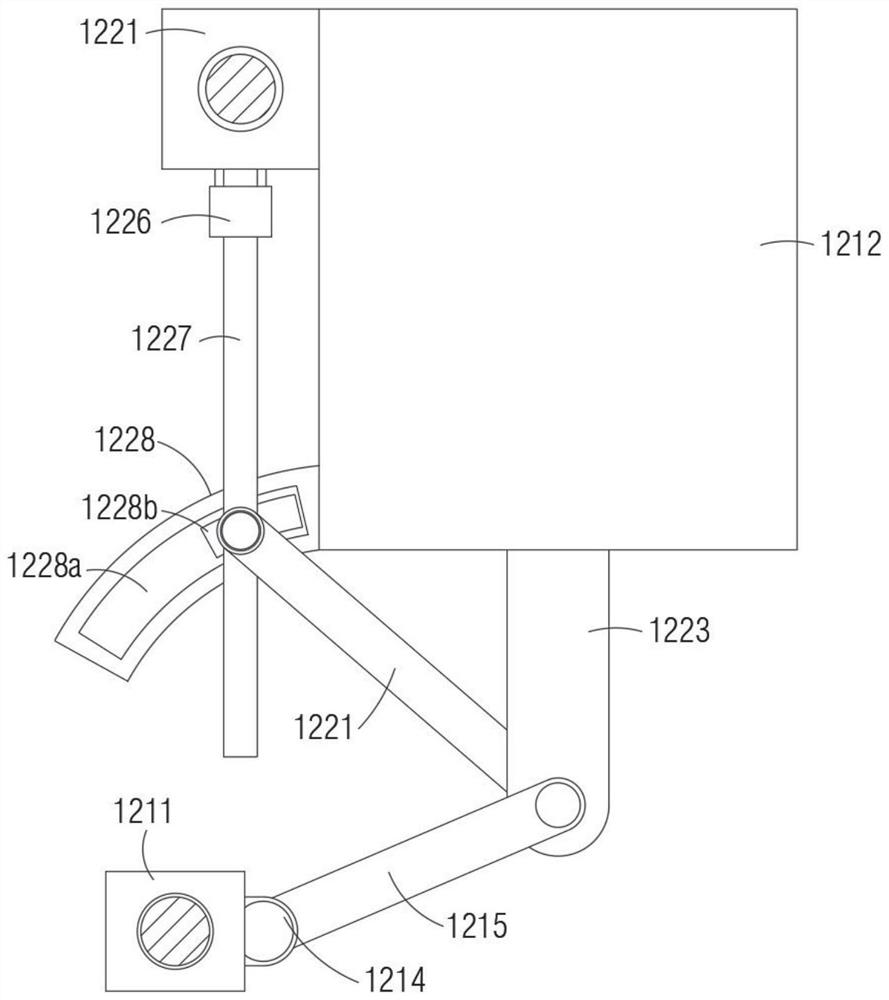

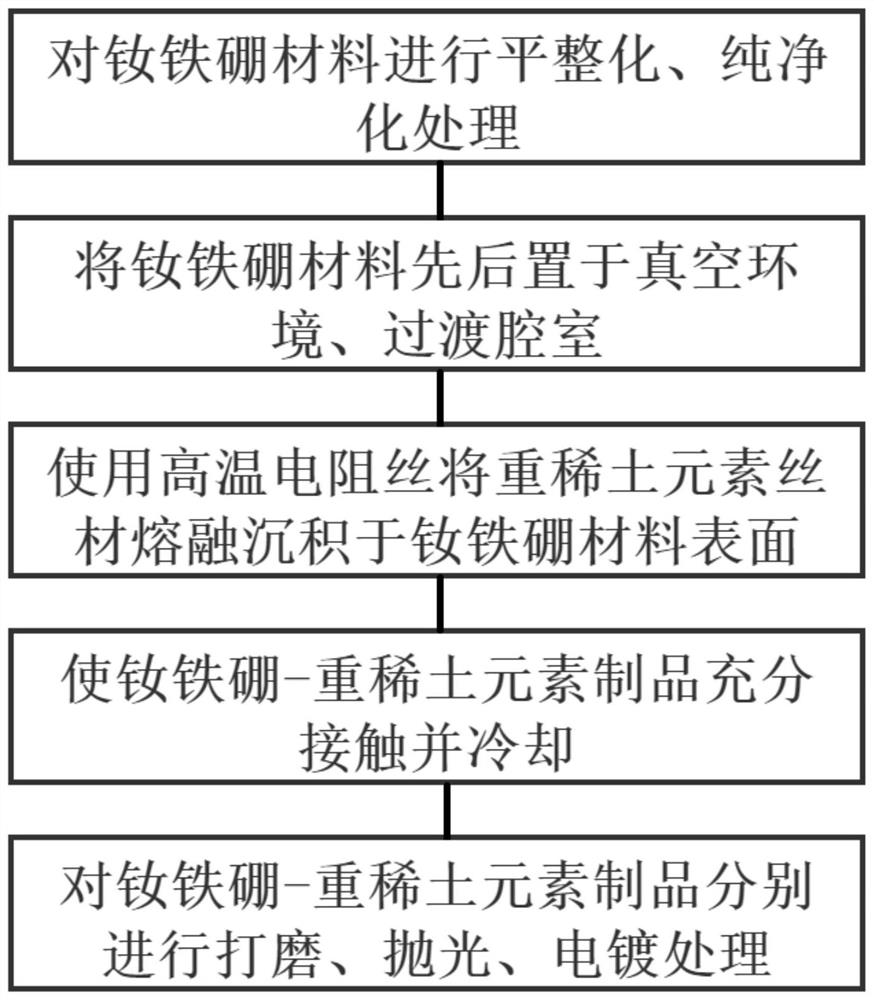

A method and equipment for fused deposition of heavy rare earth elements on NdFeB surface resistance wire

ActiveCN112626441BEvenly distributedIncrease profitMolten spray coatingInductances/transformers/magnets manufactureRare-earth elementSurface cooling

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A photoelectric direct reading spectrometer

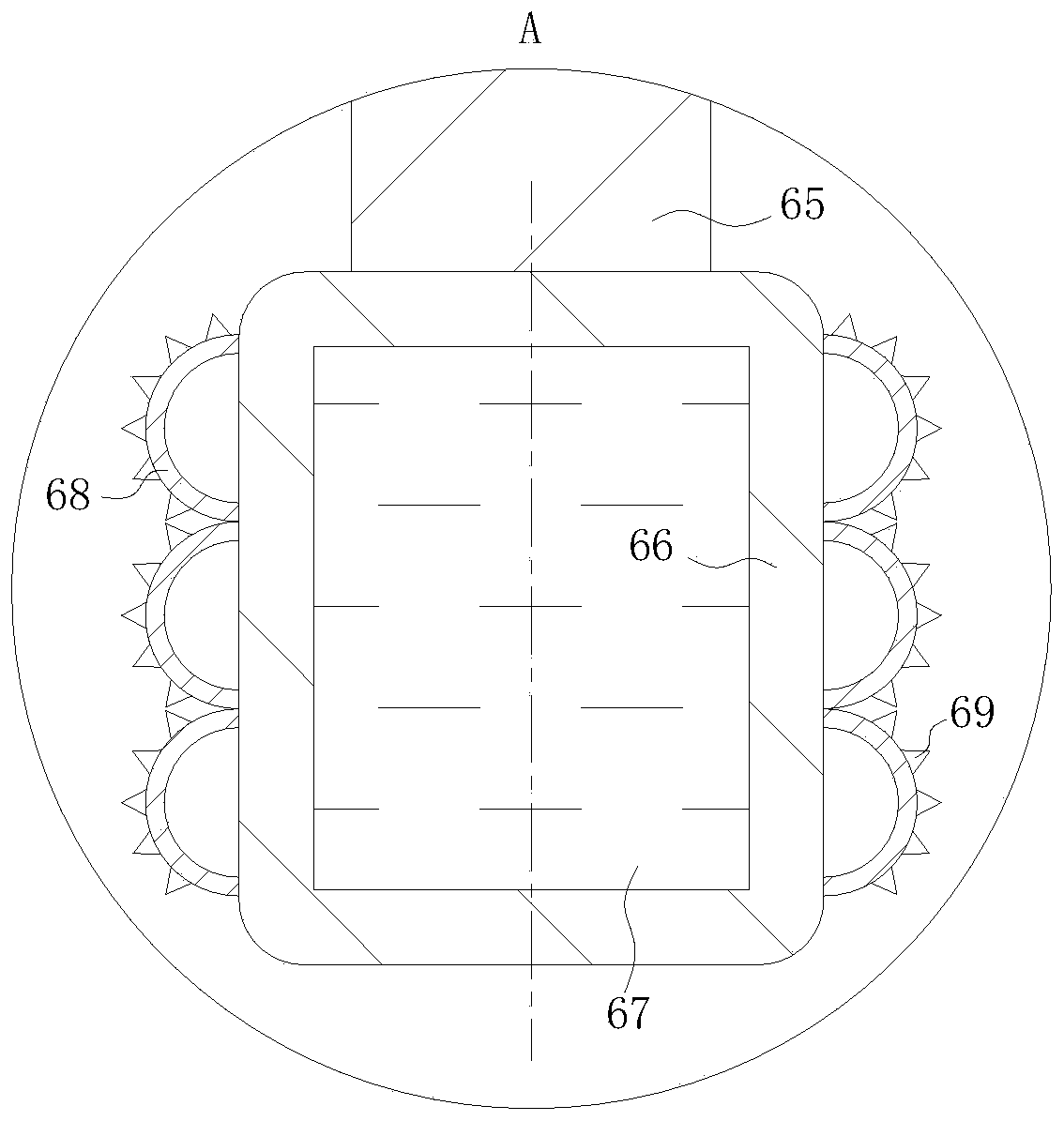

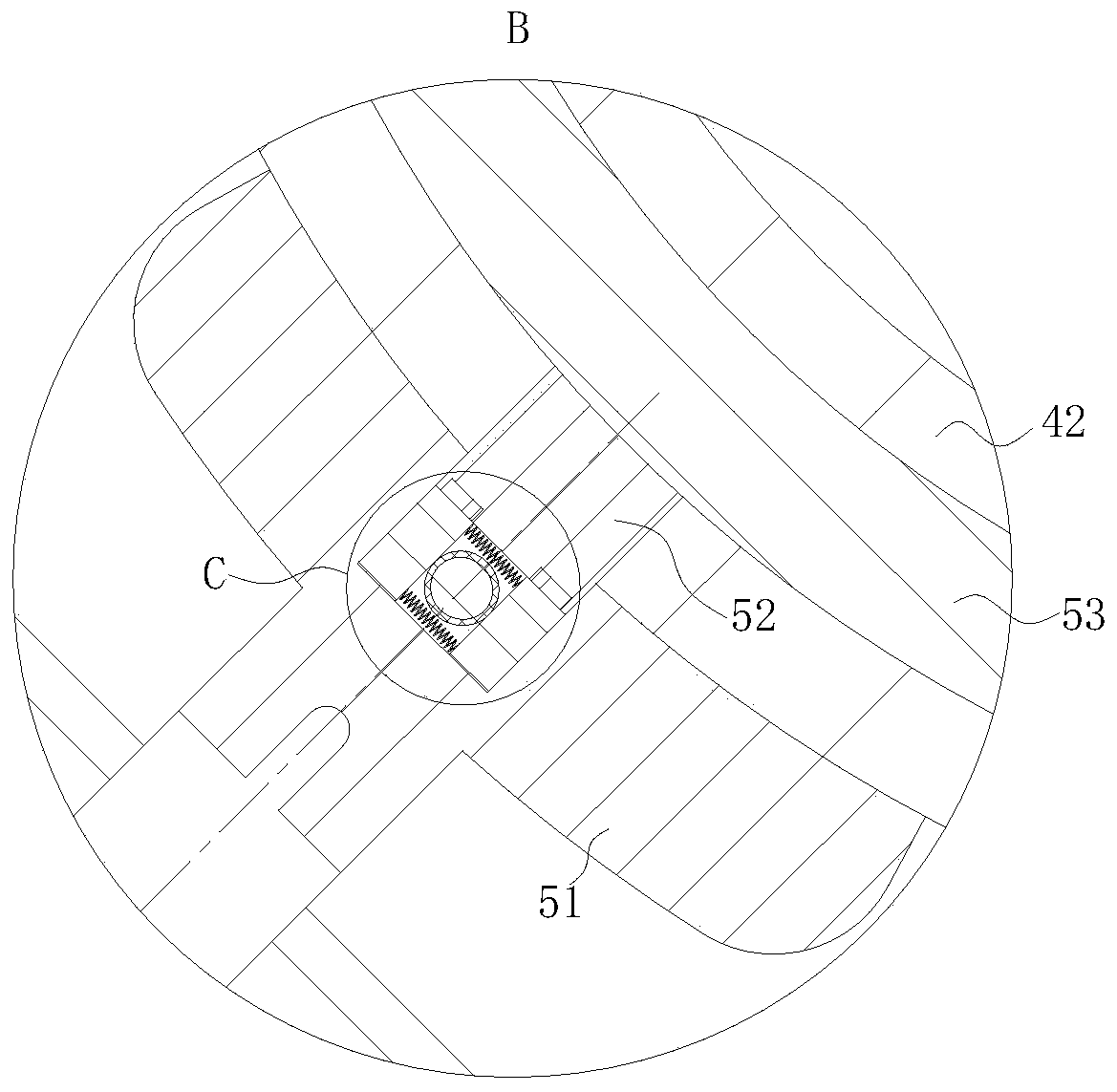

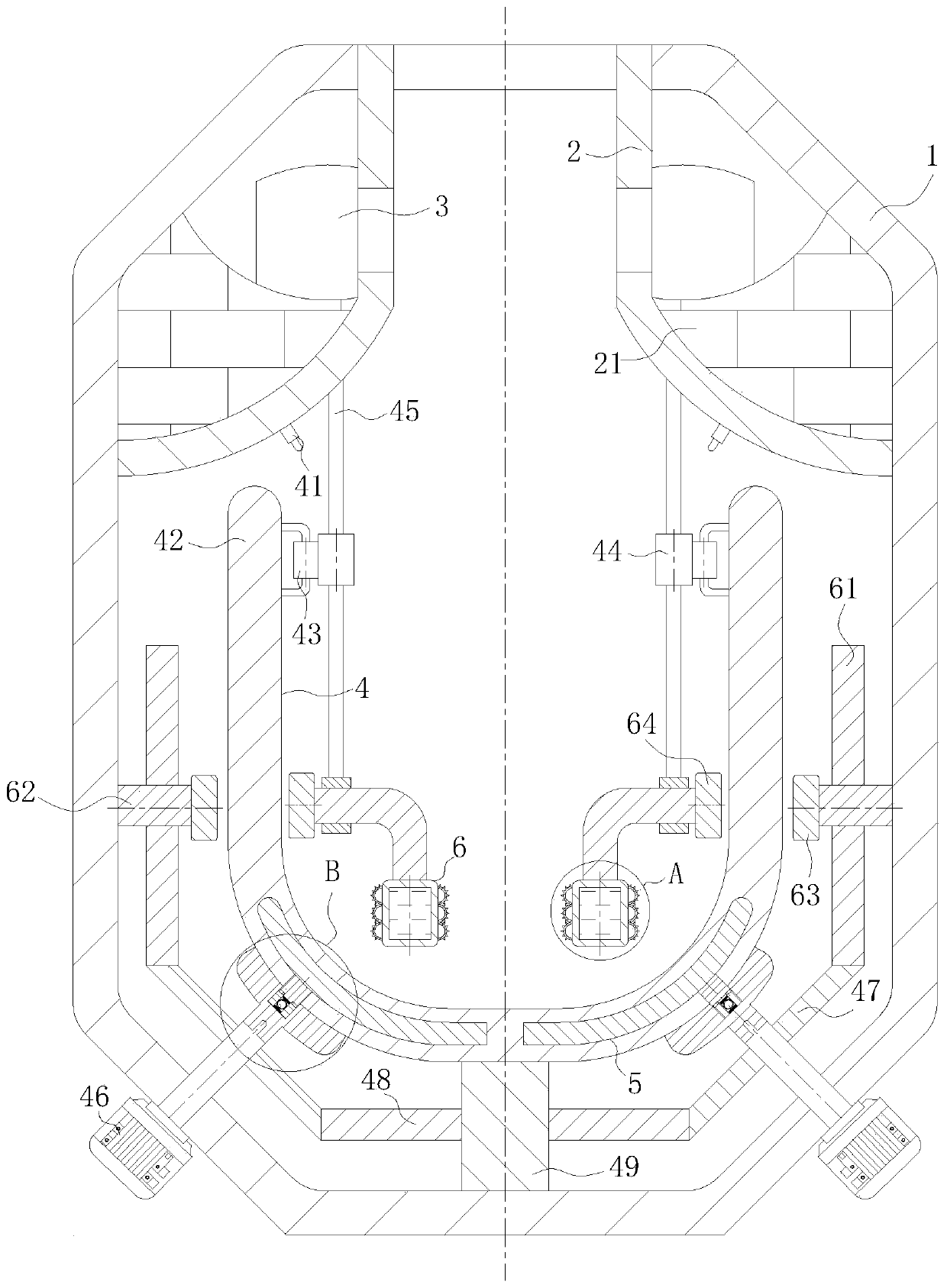

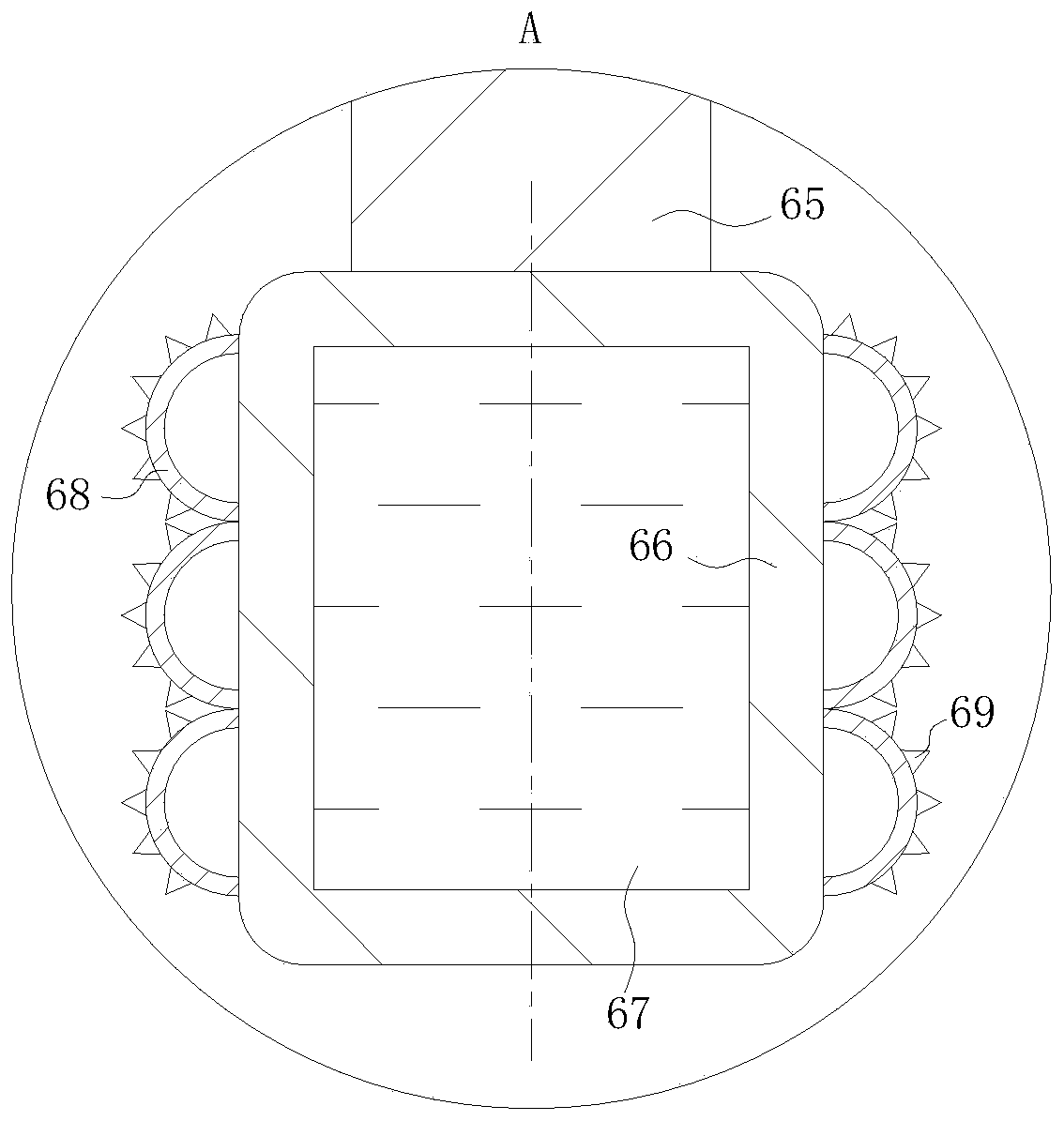

InactiveCN110186907BControl the amount of ejectionAvoid wastingAnalysis by electrical excitationEngineeringHeat conservation

The present invention belongs to the technical field of spectrum decomposition, and is specifically a photoelectric direct-reading spectrometer, which includes a main frame, a partition, a spectrometer body, a rotating heating mechanism, a heat preservation mechanism and a stirring mechanism; A partition is fixedly connected; the partition is arc-shaped, and the inner lower end of the partition is filled with an asbestos layer, and a rotating heating mechanism is arranged below the partition; the upper end of the asbestos layer is fixedly installed with a spectrometer body; the rotating heating The mechanism includes a gas jet, a rotary furnace, No. 1 flint, No. 2 flint, connecting rod, motor, bevel gear, No. 1 spur gear and No. 1 rotating column; the gas jet is fixedly installed on the lower surface of the outer end of the partition , there is a rotary furnace under the gas injection port; the invention is mainly used to solve the problem that the melting furnace in the prior art keeps the same temperature when dissolving different metals, which causes a lot of waste of heat energy and fuel, and cannot freely switch the temperature according to the melting temperature of the metal .

Owner:CHANGCHUN UNIV OF SCI & TECH

Photoelectric direct-reading spectrometer

InactiveCN110186907AControl the amount of ejectionAvoid wastingAnalysis by electrical excitationDecompositionEngineering

The invention belongs to the technical field of spectral decomposition, and specifically relates to a photoelectric direct-reading spectrometer. The photoelectric direct-reading spectrometer comprisesa main frame body, a partition plate, a spectrometer body, a rotary heating mechanism, a heat preservation mechanism and a stirring mechanism; the partition plate is fixedly connected to the two sides of the upper end of inside of the main frame body; the partition plate is arc-shaped, the lower end of the interior of the partition plate is filled with an asbestos layer, and the rotary heating mechanism is arranged below the partition plate; the spectrometer body is fixedly installed at the upper end of the asbestos layer; the rotary heating mechanism comprises an air jet hole, a rotary furnace, a No.1 flintstone, a No.2 flintstone, a connecting rod, a motor, a bevel gear, a No.1 straight gear and a No.1 rotating column; and the air jet hole is fixedly installed at the lower surface of the outer end of the partition plate, and the rotary furnace is arranged below the air jet hole. The photoelectric direct-reading spectrometer provided by the invention is mainly used for solving the problem that a large amount of heat energy waste and fuel waste are caused due to the fact that the temperature of a dissolving furnace in the prior art is kept consistent when different metals are dissolved, and the temperature cannot be freely switched according to the melting temperature of the metals.

Owner:CHANGCHUN UNIV OF SCI & TECH

Belt laser cutting automatic equipment

ActiveCN106271112BDiffuse fullyControl the amount of ejectionWelding/soldering/cutting articlesMetal working apparatusLaser cuttingEngineering

The invention relates to automatic equipment, in particular to automatic equipment for laser cutting of a belt. The fully automatic equipment for the laser cutting of the belt comprises a laser device, a water spraying mechanism, a traction mechanism, a material conveying mechanism, a working table and a bracket, wherein the working table is fixedly connected to the bracket; the traction mechanism is fixedly connected to the working table; the material conveying mechanism is fixedly connected to the working table; the water spraying mechanism is fixedly connected to the bracket; the laser device is fixedly connected to the bracket; the laser device is located above the working table. Due to the cooperative operation of the water spraying mechanism, the traction mechanism and the material conveying mechanism, the operations such as stretching, cutting and material falling are repeatedly performed so as to fully automatically realize automatic laser cutting of the belt and control the laser cutting effect of the belt; and therefore, the production efficiency and the quality of a product are improved.

Owner:滁州辉煌无纺科技有限公司

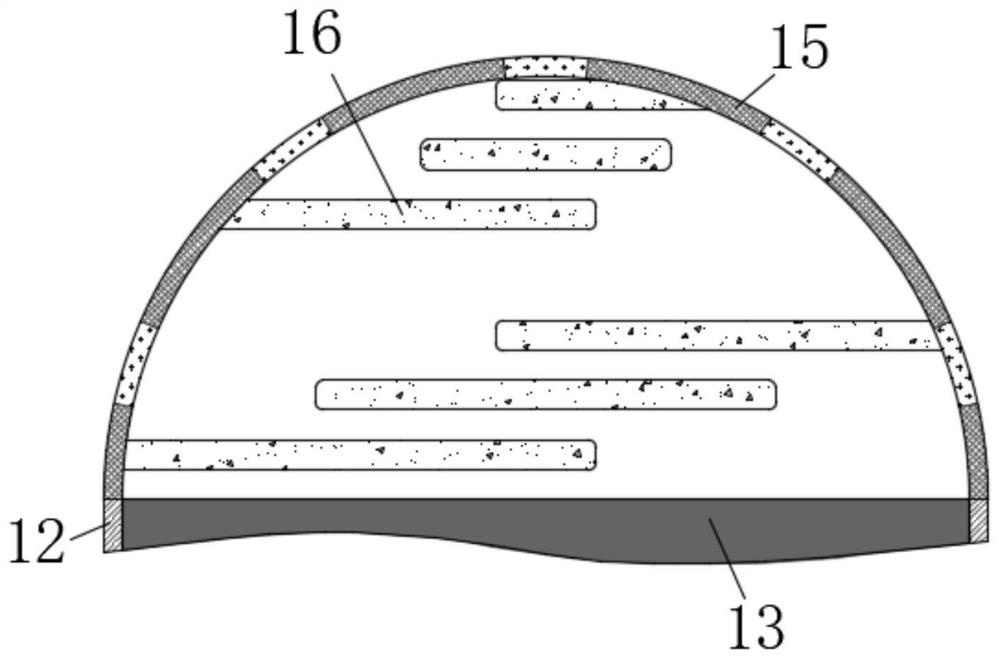

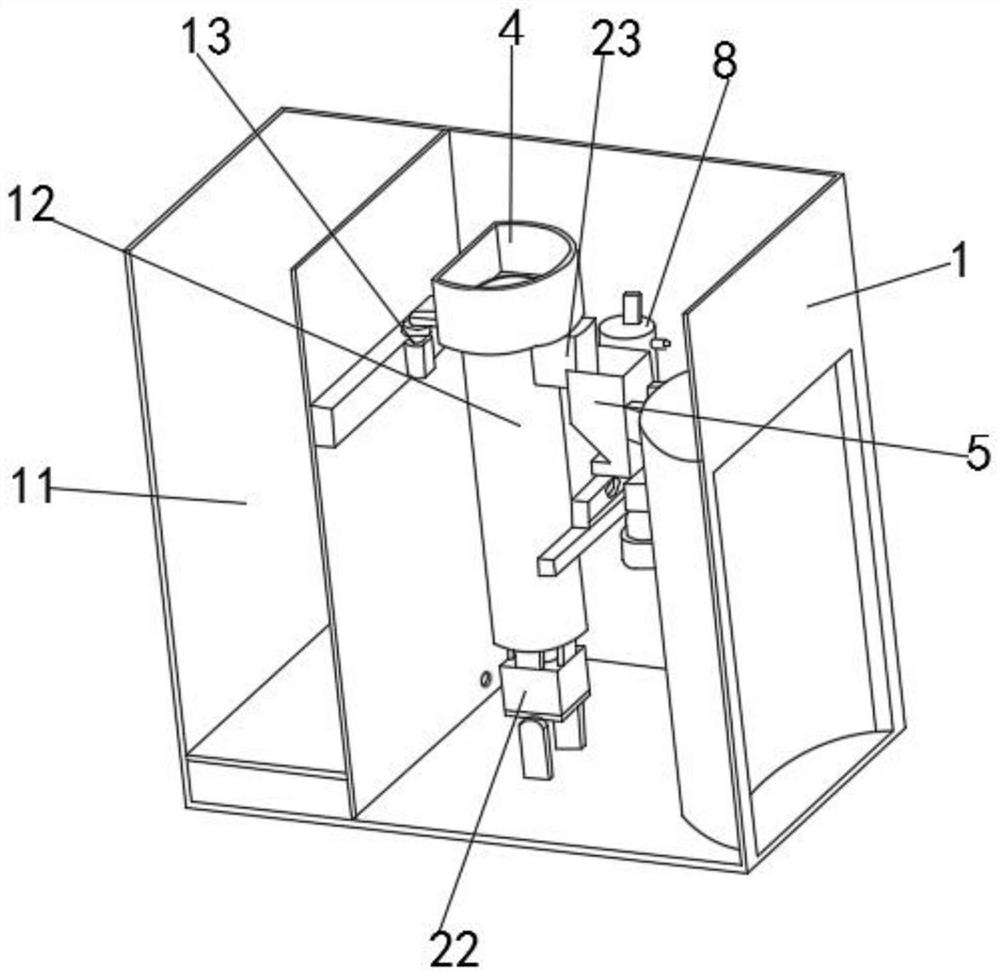

Spray gas disinfection device for preventing infectious diseases and method thereof

PendingCN114748669AControl the amount of ejectionSave sanitizerAtomized substancesDrive shaftElectric machine

The invention provides a droplet gas disinfection device for preventing infectious diseases and a method thereof, and belongs to the technical field of medical epidemic prevention equipment.The droplet gas disinfection device for preventing the infectious diseases comprises a conveying mechanism, an adjusting mechanism and a movement mechanism, the conveying mechanism comprises a barrel, at least two conveying assemblies, a first connecting shaft, a second connecting shaft, a first motor and a second motor, a conveying cavity is formed in the barrel, the two conveying assemblies are arranged in the conveying cavity, the two conveying assemblies are connected through the first connecting shaft and the second connecting shaft respectively, and the first motor and the second motor are arranged in the conveying cavity. The first motor and the second motor are both arranged on one side of the other conveying assembly. A seventh motor is electrified to drive a driving shaft and enable a third bevel gear to rotate, a rotating shaft and two third gears are driven to rotate through a fourth bevel gear, and a cam type tooth block can drive an atomizing nozzle to turn over, so that the atomizing nozzle can adapt to a complex environment through multi-angle adjustment.

Owner:中国人民解放军海军第九七一医院

Method and device for fused deposition of heavy rare earth elements on neodymium-iron-boron surface resistance wire

ActiveCN112626441AEvenly distributedIncrease profitMolten spray coatingInductances/transformers/magnets manufactureRare-earth elementSurface cooling

The invention discloses a method and device for fused deposition of heavy rare earth elements on a neodymium-iron-boron surface resistance wire, relates to the technical field of permanent magnet material manufacturing, and mainly aims to solve the problems that an existing method for deposition of heavy rare earth elements on the surface of a neodymium-iron-boron permanent magnet material is complex in process and uneven in distribution of the heavy rare earth elements. The method for fused deposition of the heavy rare earth elements on the neodymium-iron-boron surface resistance wire comprises the following steps that S1, a neodymium-iron-boron permanent magnet material is pre-treated; S2, the neodymium-iron-boron permanent magnet material is introduced into a vacuum chamber and a transition chamber; S3, a resistance wire melting nozzle melts the wire containing the heavy rare earth elements and deposits the wire on the surface of the neodymium-iron-boron permanent magnet material; and S4, cooling is carried out. The device for fused deposition of the heavy rare earth elements on the neodymium-iron-boron surface resistance wire structurally comprises a conveyor belt, and an acidification pool, an isostatic pressing chamber, a vacuum chamber, a transition chamber, a fused deposition chamber and a cooling chamber are sequentially arranged along the conveyor belt. According to the method and device for fused deposition of the heavy rare earth elements on the neodymium-iron-boron surface resistance wire, the heavy rare earth elements can be uniformly deposited on the surface of the neodymium iron boron permanent magnet material through the fused deposition method of the resistance wire, and meanwhile the preparation process is further simplified.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Pressing type temperature-sensitive color-changing perfume bottle

ActiveCN109850371AAvoid wastingReduce wasteClosuresDomestic cooling apparatusFirst glassesInsulation layer

The invention relates to the technical field of perfume bottles, in particular to a pressing type temperature-sensitive color-changing perfume bottle. The pressing type temperature-sensitive color-changing perfume bottle comprises a first glass layer, a color-changing layer and a pressing device; the pressing device is arranged at the top of the first glass layer; a water outlet pipe is arranged at the bottom of the pressing device and extends into the perfume bottle; the color-changing layer is arranged on the inner side of the first glass layer; a heat insulation layer is arranged on the inner side of the color-changing layer; and a second glass layer is arranged on the inner side of the heat insulation layer. With the arrangement of the heat insulation layer, a perfume in the perfume bottle is prevented from being volatilized due to excessive external temperature; with the arrangement of a flow controller, the spraying amount of the perfume can be effectively controlled and unnecessary waste is reduced; with the arrangement of the color-changing layer, the perfume bottle has a color-changing function, so that the perfume bottle appears more dazzling under the irradiation of light, and the attention of the perfume bottle is improved.

Owner:陆杭峰

Dust removal device and method for manufacturing same

InactiveCN102527666AControl the amount of ejectionSimple manufacturing methodCleaning using gasesFluff pulpPerlite

The invention relates to a dust removal device and a method for manufacturing the same. The dust removal device comprises an aerosol tank, the aerosol tank comprises a cylinder and a valve, the valve is arranged on the cylinder, propellants and adsorption materials are filled in the cylinder, and the adsorption materials include one or a few of nonwoven fabrics, fluff pulp, wood pulp cotton, broken cotton velvet, cotton gauzes, toilet paper, cotton rags, vermiculite powder and expanded perlite powder. The adsorption materials adsorb all or most of the propellants, liquid propellants cannot flow out and can be sprayed in any directions, and the spray quantity can be effectively controlled. Besides, the method for manufacturing the dust removal device is simple and is easy to implement.

Owner:广东好顺欧迪斯科技股份有限公司

Presswork dampening device

InactiveCN109955585AControl the amount of ejectionImprove wettabilityPrinting press partsMotor driveInlet valve

The invention provides a presswork dampening device. The device comprises supports, a motor, a main rotary shaft, an auxiliary rotary shaft, a steam generator, a water inlet pipe and a conveying belt.A water inlet valve is arranged on the water inlet pipe. The motor drives the main rotary shaft to rotate, and accordingly, the auxiliary rotary shaft is driven. The presswork dampening device further comprises a humidity sensor used for detecting presswork humidity. The steam generator is provided with a plurality of air guide pipes. A regulating valve is arranged on each air guide pipe. An exhaust pipe is arranged on the air guide pipes in a communicating mode and perpendicularly arranged below the conveying belt. A plurality of air spray holes are formed uniformly in the upper portion of the exhaust pipe. According to the presswork dampening device, since the humidity sensor is arranged, a steam control module and a time adjusting button are arranged in the steam generator, the steam spray-out amounts can be effectively controlled, the paper presswork dampening effect is made better, the paper presswork yield is greatly increased, the production efficiency is improved, and the production cost is lowered.

Owner:天津金茂鸿顺电动自行车有限公司

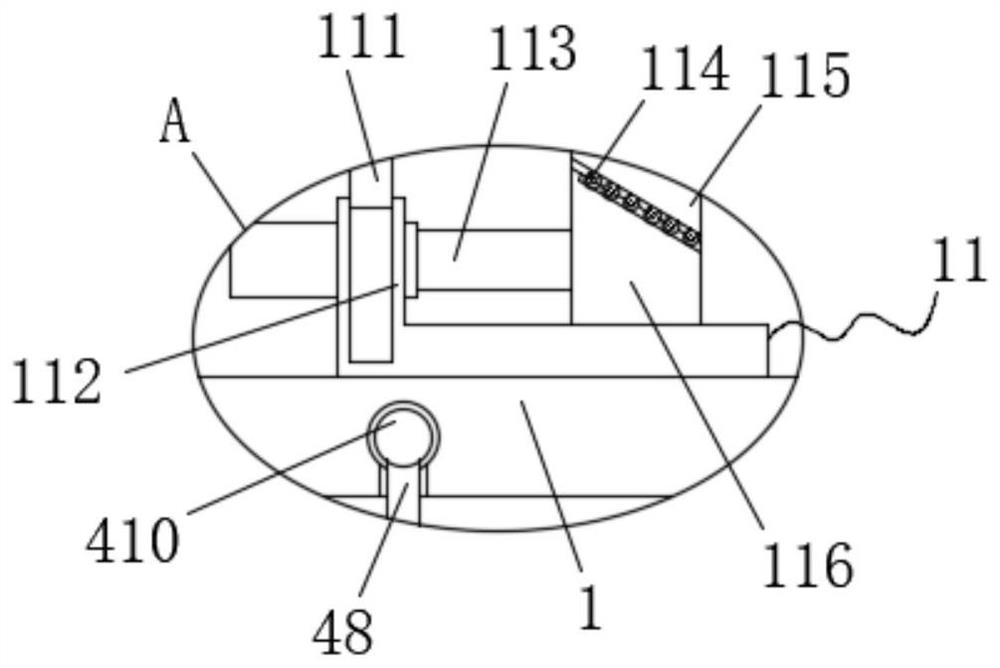

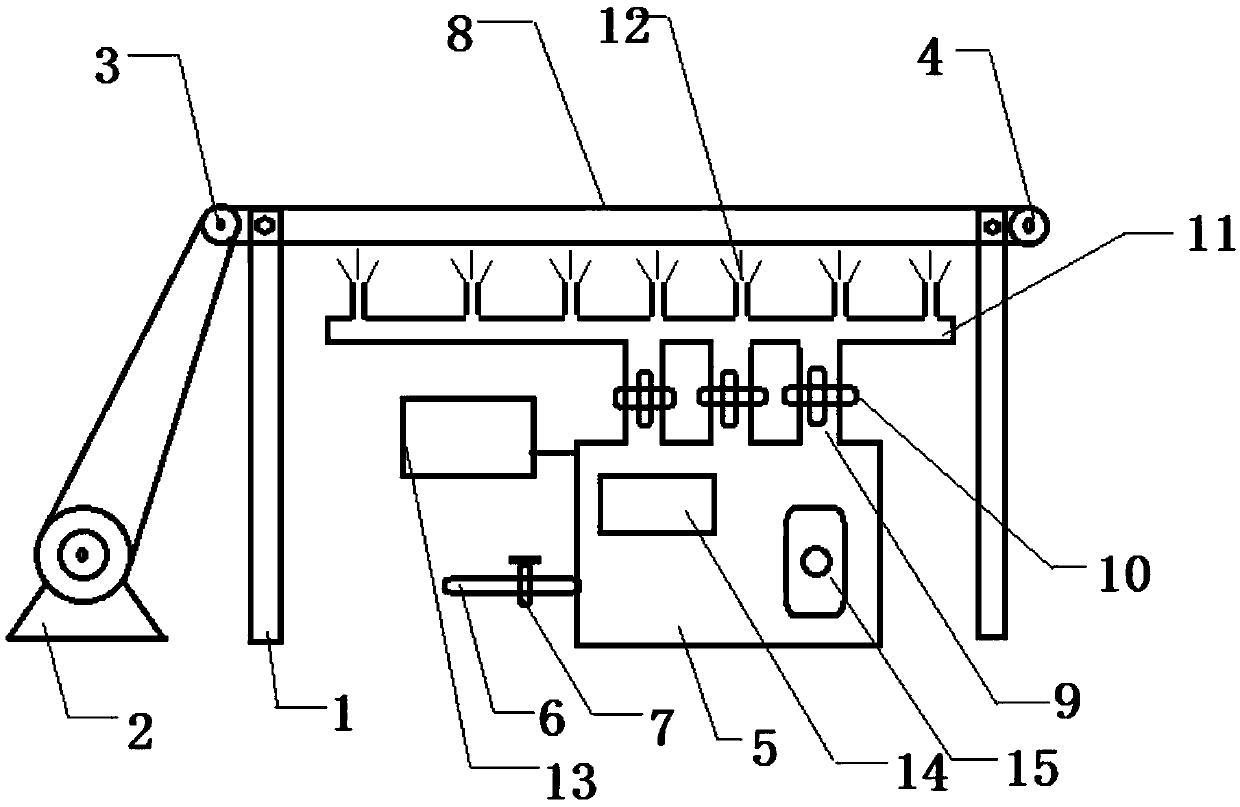

Multifunctional automatic tea maker for household use

ActiveCN111067359BReduce stepsImprove your own functionalityBeverage vesselsElectric machineryTea leaf

The invention discloses a family-used multifunctional automatic tea maker, which comprises a box shell, a material storage barrel, a rotating card holder, a heating tube and a vibrating upper cover. The material storage barrel is fixedly installed inside the box body shell, and A motor is fixedly installed on the inner surface of the body shell near the side of the storage tank. The vibrating upper cover is movably installed on the upper end of the storage tank. An eccentric wheel is installed on the upper end of the motor, and a transmission rod is provided on the upper part of the eccentric wheel. , the eccentric wheel and the vibrating upper cover are connected through a transmission rod, the bottom of the storage barrel is fixedly equipped with a transmission mechanism, and the upper part of the transmission mechanism is equipped with a lifting ejector rod; The tea maker can make it have an automatic tea adding structure, and at the same time, it can adjust the amount of tea added arbitrarily according to the user's needs, flexibly control the concentration of tea flavor, and at the same time make it have a cup auxiliary fixing structure to improve its safety and avoid cup rollover.

Owner:WEST ANHUI UNIV

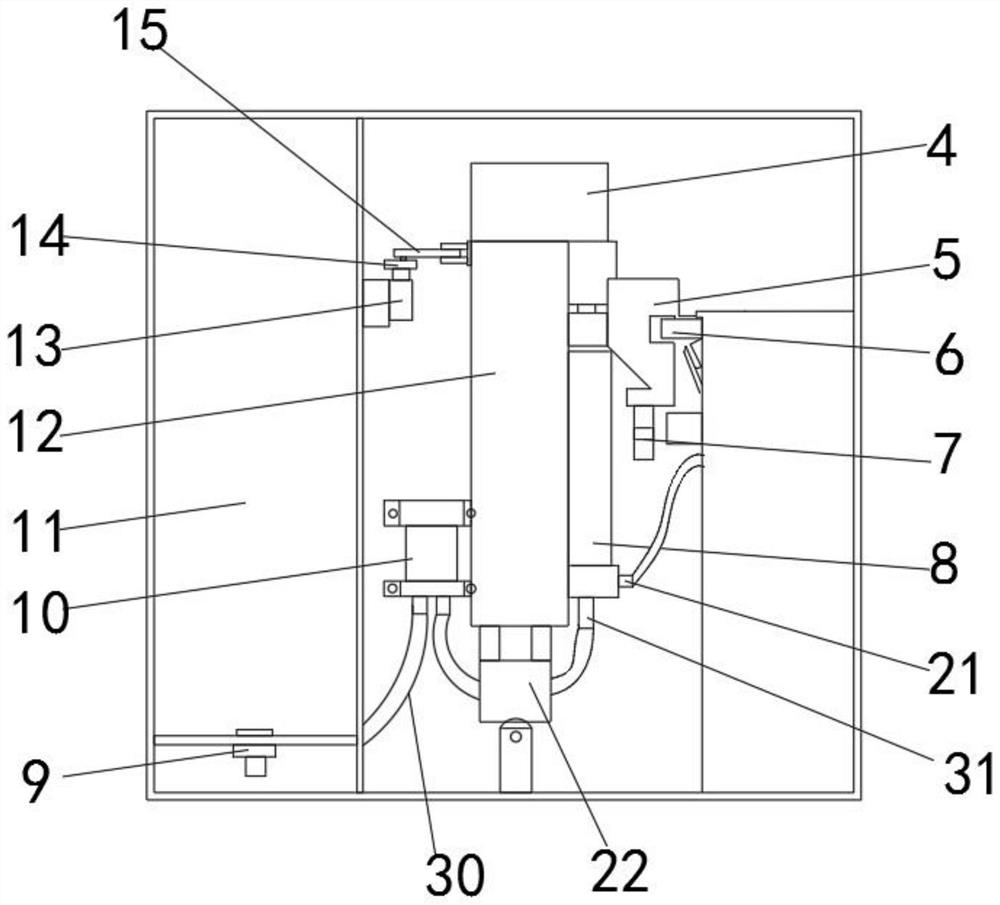

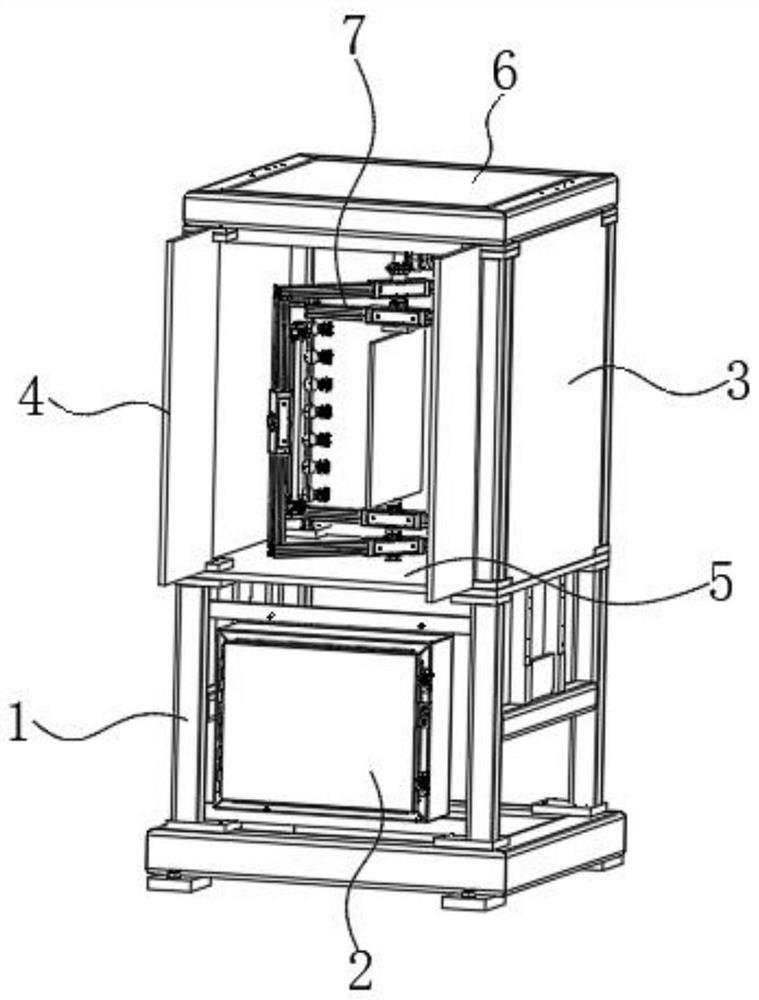

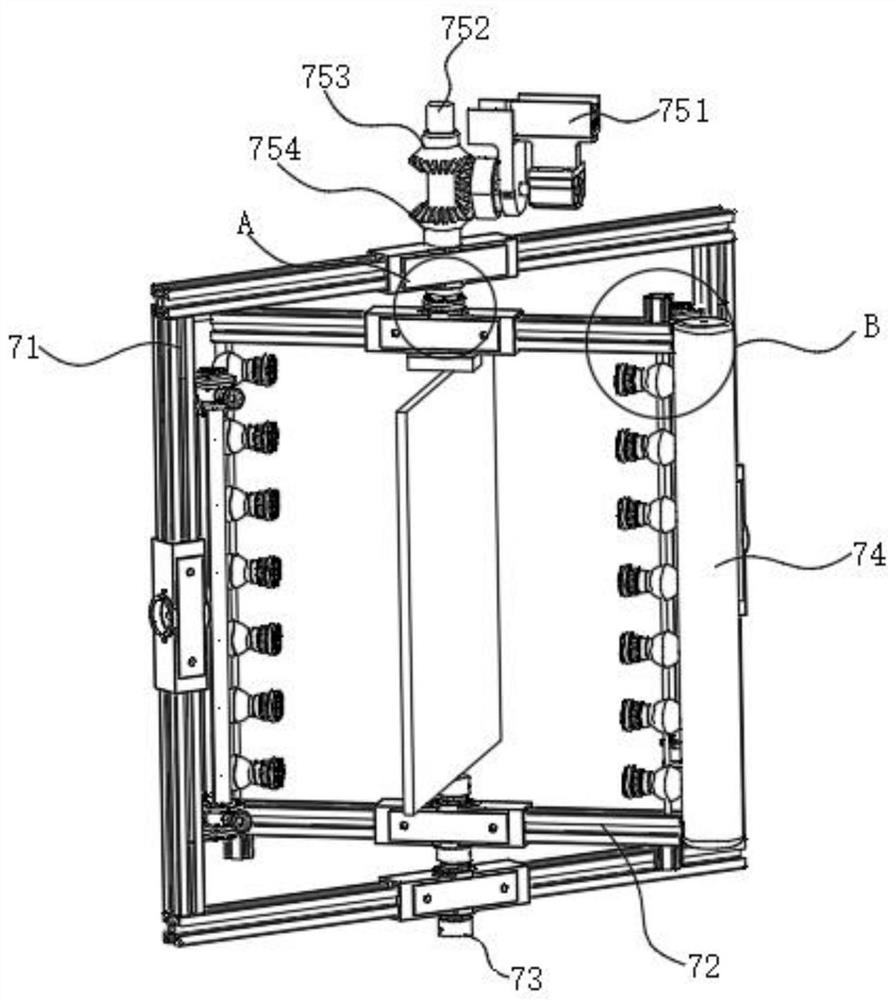

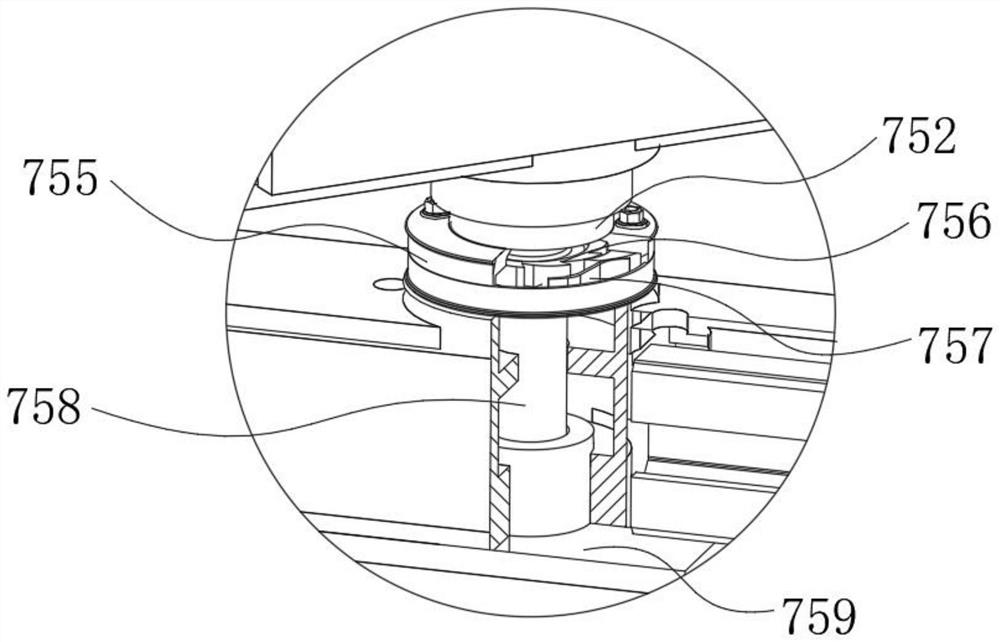

Solid wood furniture paint spraying device

The invention discloses a solid wood furniture paint spraying device, and relates to the technical field of solid wood furniture paint spraying. The solid wood furniture paint spraying device comprises a lower support, an electric control box, an upper support and a paint spraying assembly, wherein the electric control box is fixed to the side face of the lower support and used for controlling operation of the device; the upper support is fixed to the upper end face of the lower support, and a top plate and a bottom plate are fixed to the upper end and the lower end of the upper support correspondingly; transparent plates are arranged on the periphery of the upper support and used for observing sprayed paint in real time, and the transparent plate on one side can be opened and closed and used for allowing solid wood furniture to get in and out; and the paint spraying assembly is rotationally arranged between the top plate and the bottom plate and used for spraying paint to the solid wood furniture and drying the solid wood furniture. According to the solid wood furniture paint spraying device, the solid wood furniture can be dried while being sprayed with paint through the paint spraying assembly, the paint spraying efficiency is improved, the sagging phenomenon generated during paint spraying is further prevented, and the paint spraying quality is improved.

Owner:宁波市安道工业设计有限公司

Automatic particle emulsification device and preparation method of emulsified particles

InactiveCN105582867AImprove stabilityReduce particle countMicroballoon preparationMicrocapsule preparationStatic mixerCirculating pump

The invention provides an automatic particle emulsification device and a preparation method of emulsified particles. The automatic particle emulsification device comprises a tank A, a tank B, particle generators, retainer rings, a liquid level sensor, a circulating pump and a delivery pump. The upper part or top of the tank A is provided with two particle generators. The retainer ring is arranged around each of the two particle generators. The upper part or top of the tank B is also provided with a particle generator. The bottom of the tank is provided with two water outlets, wherein one water outlet is communicated to an inlet of a static mixer tube A after passing through the circulating pump. An outlet of the static mixer tube A is communicated with a particle generator. The other water outlet is communicated to the particle generator of the tank B after passing through the delivery pump. The liquid level sensor is arranged in the tank A and can detect liquid level in the tank A at any time. The device and the method of the invention have advantages of high efficiency, high stability of the prepared particle system, good uniformity and small particle size.

Owner:曾小强 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com