Method and equipment for laser cladding of heavy rare earth wire on surface of neodymium iron boron

A laser cladding and NdFeB technology is applied in the fields of magnetic materials, inductance/transformer/magnet manufacturing, electrical components, etc. It can solve the problems of uneven distribution of heavy rare earth elements, complex process, poor bonding performance, etc., and achieve weight reduction. The effect of the amount of rare earth elements, improving the binding performance and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

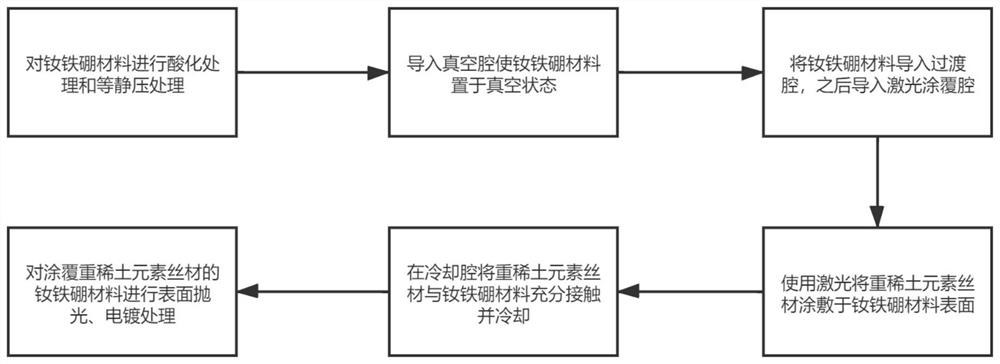

[0039] Such as figure 1 As shown, the present invention discloses a method for laser cladding heavy rare earth wire on the surface of NdFeB, comprising the following steps:

[0040] S1, pretreating the NdFeB permanent magnet material;

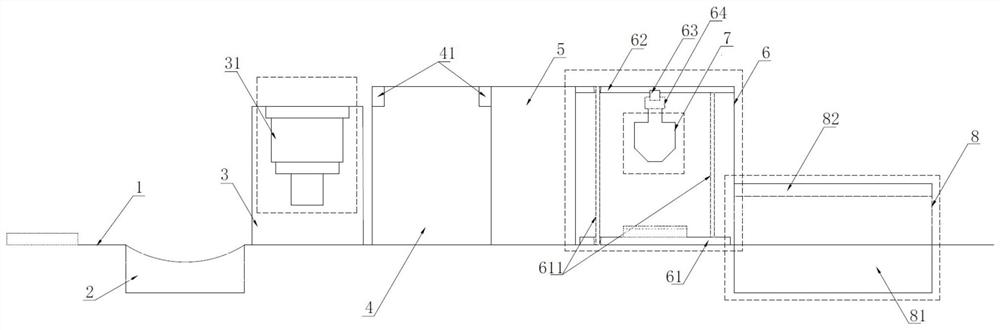

[0041] S2. Introduce the NdFeB permanent magnet material into the vacuum chamber 4 and the transition chamber 5 in sequence to complete the process of smoothly transitioning from the air environment to the vacuum environment;

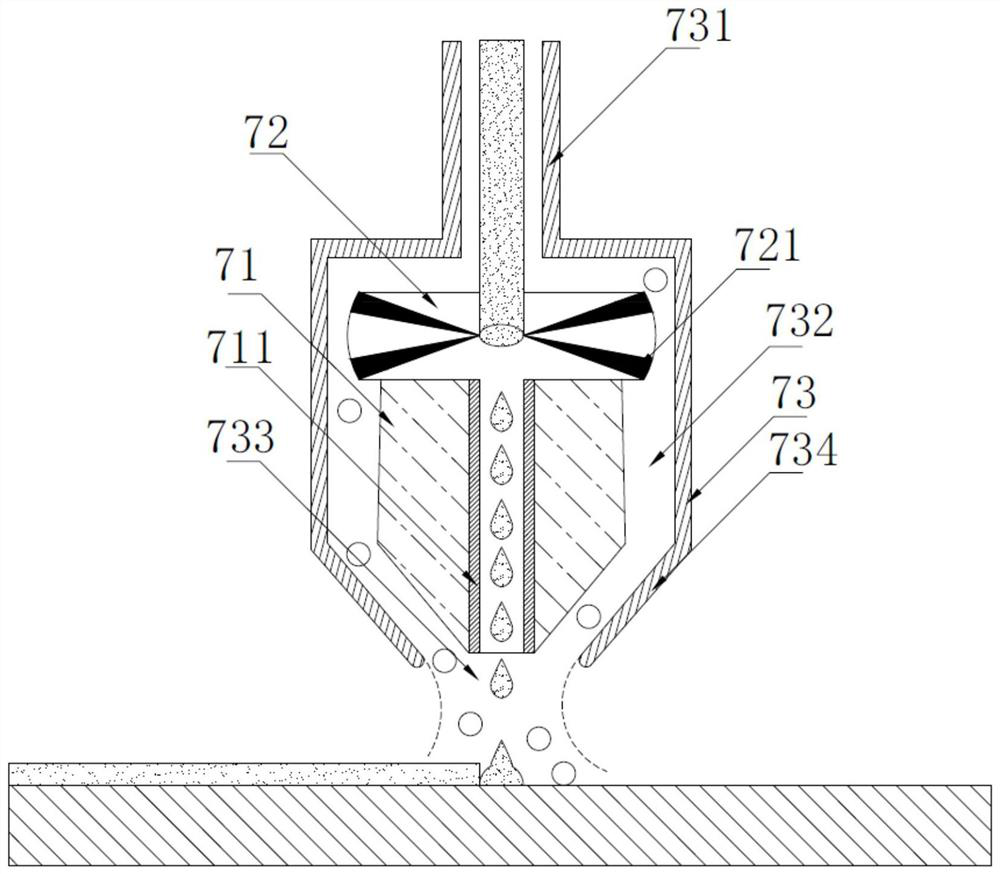

[0042] S3. Introduce the NdFeB permanent magnet material into the coating chamber 6, use the laser coating nozzle 7 to heat and melt the wire material containing heavy rare earth elements, and coat the melt on the surface of the NdFeB permanent magnet material, laser coating The distance between the coating nozzle 7 and the NdFeB permanent magnet material is about 1 to 2mm, and the wetting angle between the melt and the NdFeB permanent magnet material substrate is kept in the range of 30° to 75°;

[0043] S4. Introduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com