Presswork dampening device

A technology of printed matter and humidity sensor, applied in the field of printing machinery supporting facilities, can solve the problems of paper printed matter turning into scraps and scraps, poor wetting effect, etc., and achieve the effects of good wetting effect, lower production cost, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

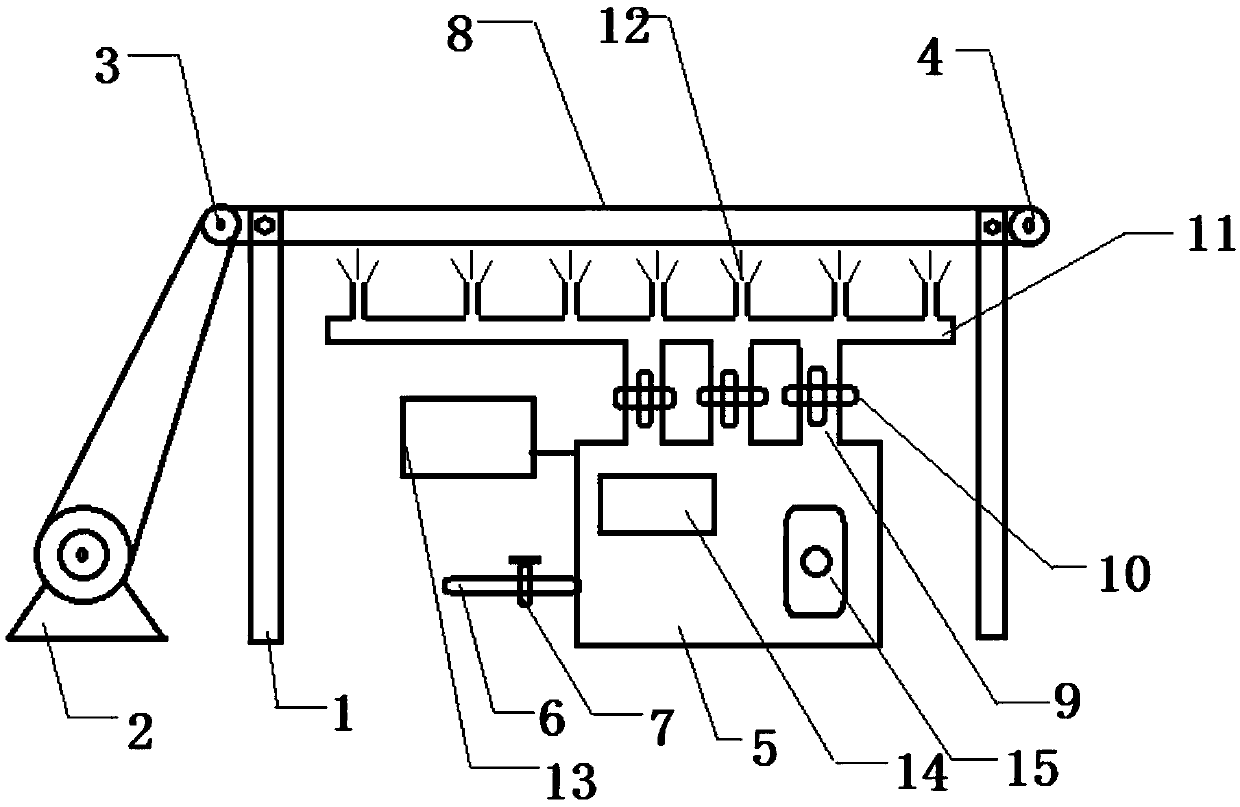

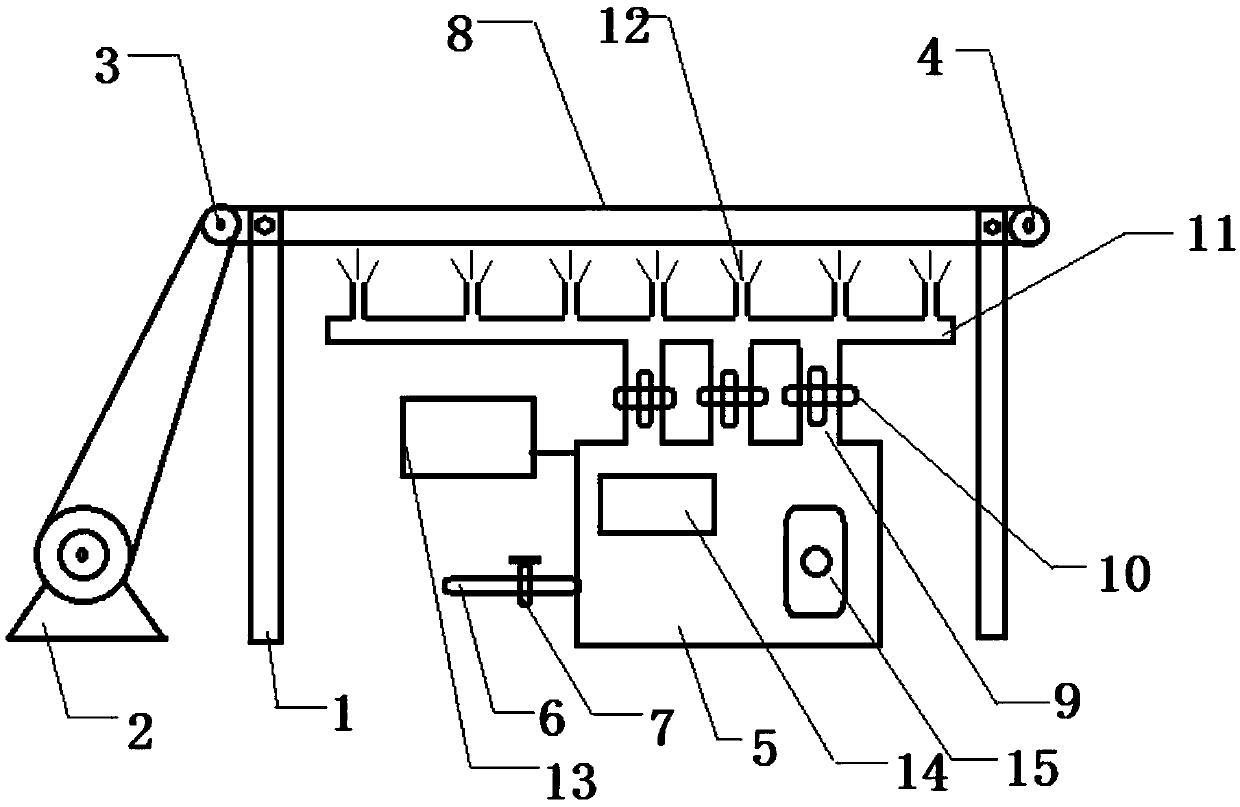

[0018] figure 1 It shows a schematic structural diagram of a printed matter dampening device according to an embodiment of the present invention;

[0019] Such as figure 1 As shown, a printed matter wetting device includes a bracket 1, a motor 2, a main rotating shaft 3, an auxiliary rotating shaft 4, a steam generator 5, a water inlet pipe 6 and a conveyor belt 8, and the water inlet pipe 6 is provided with a water inlet valve 7. The motor 2 drives the main rotating shaft 3 to rotate, thereby driving the auxiliary rotating shaft 4, and also includes a humidity sensor 13, the humidity sensor 13 is used to detect the humidity of the printed matter, and the steam generator 5 is provided with multiple Each air guide pipe 9 is provided with a regulating valve 10 on each of the air guide pipes 9, and the air guide pipe 9 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com