Spray gas disinfection device for preventing infectious diseases and method thereof

A disinfection device and infectious disease technology, applied in the direction of atomizing substances, etc., can solve the problems of inability to realize angle and height adjustment, variable liquid supply, etc., and achieve the effect of saving disinfectant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

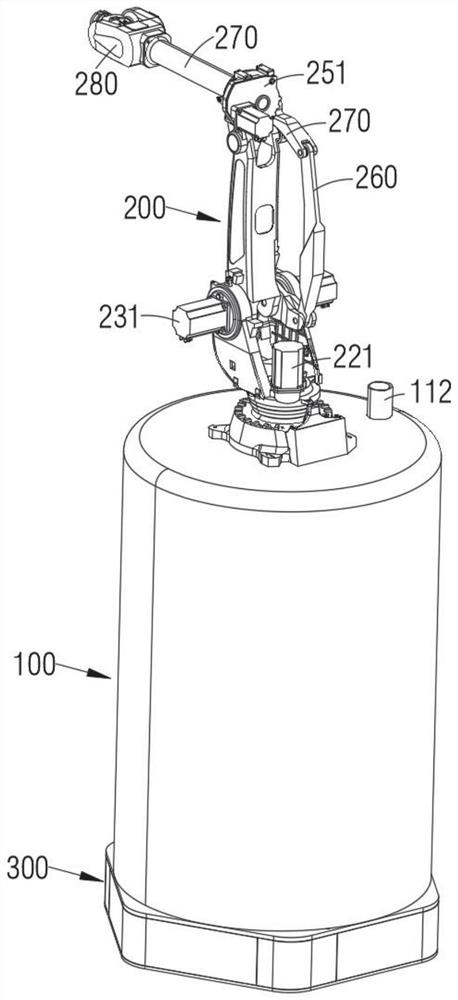

[0041] Refer to the attached Figures 1 to 7 As shown, the present invention provides a technical solution: a droplet gas disinfection device for infectious disease prevention, comprising a conveying mechanism 100, an adjusting mechanism 200 and a movement mechanism 300;

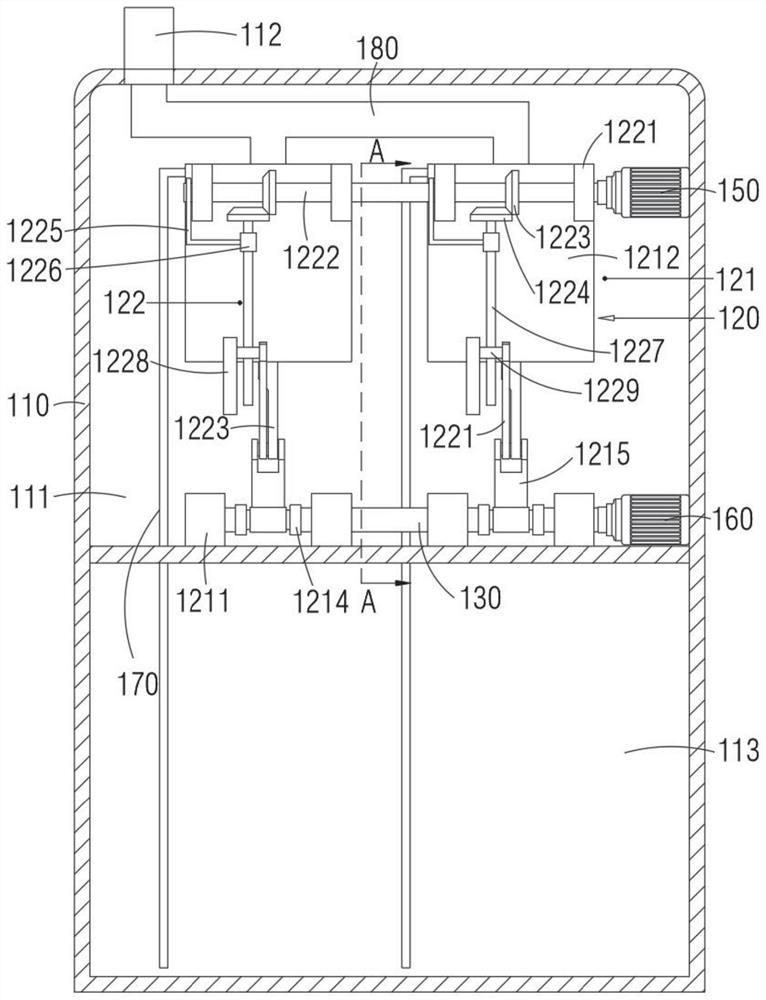

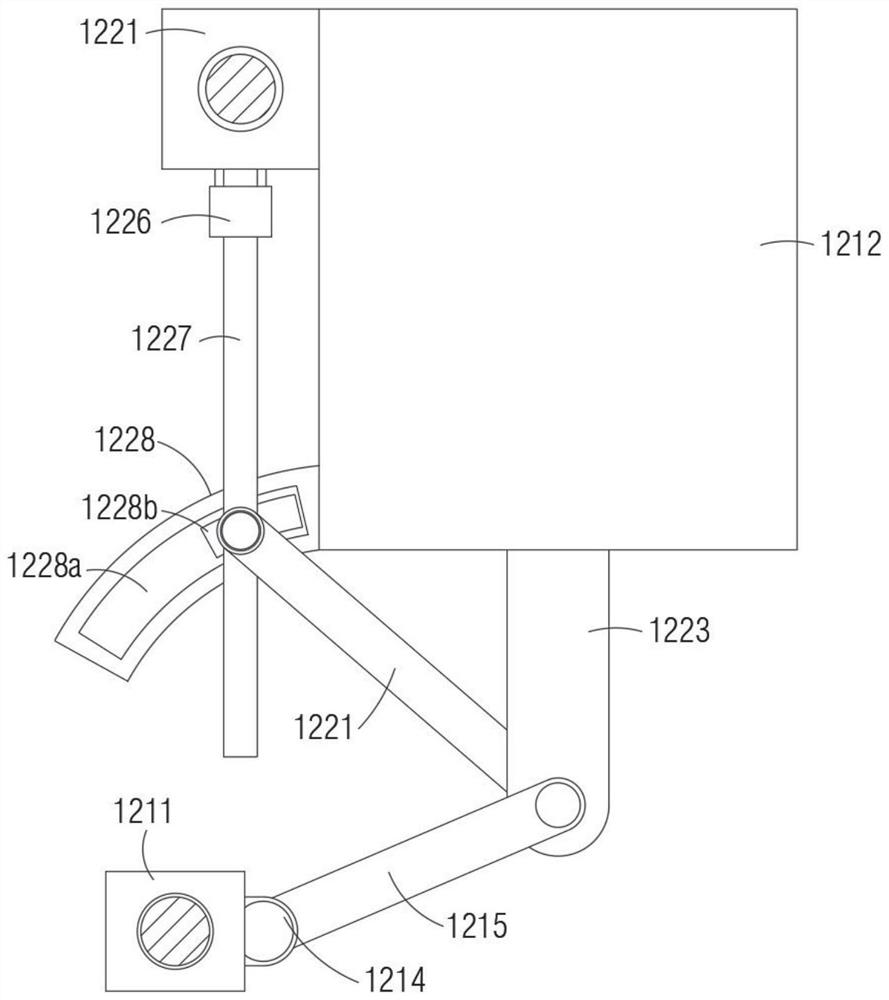

[0042] Refer to the attached Figures 1 to 4 As shown, the conveying mechanism 100 includes a cylindrical body 110, at least two conveying assemblies 120, a first connecting shaft 130, a second connecting shaft 140, a first motor 150 and a second motor 160. The cylindrical body 110 has a conveying cavity 111 therein. The two conveying assemblies 120 are arranged in the conveying cavity 111 , the two conveying assemblies 120 are respectively connected by the first connecting shaft 130 and the second connecting shaft 140 , and the first motor 150 and the second motor 160 are both arranged in the other conveying assembly 120 . One side is used to drive the two conveying assemblies 120 to carry out reciprocatin...

Embodiment 2

[0063] Refer to the attached Figure 8 As shown, the use method of the droplet gas disinfection device for infectious disease prevention provided by the embodiment of the present invention further comprises the following steps:

[0064] S1, Disinfectant delivery: the second motor 160 is energized to drive the crankshaft 1214 to rotate, the first connecting plate 1215 pushes or pulls the push rod 1213 to drive the piston 1213a to reciprocate up and down, and when the piston 1213a is pushed, the disinfectant is extruded from the liquid outlet 1212a to the The second conveying pipe 180 finally reaches the atomizing nozzle 290. When the piston 1213a is pushed, the disinfectant in the storage chamber 113 is sucked into the metering cylinder 1212, so that the two conveying assemblies 120 are pushed and pulled to achieve uninterrupted liquid supply;

[0065] S2, capacity adjustment: the first motor 150 is energized to drive the synchronizing shaft 1222 to drive the first bevel gear 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com