Multi-head discharging device of wet spraying machine

A discharge device and wet spraying machine technology, applied in the direction of shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of unable to adjust the size of the discharge flow, and the discharge of wet sprayed concrete can not be effectively controlled, so as to improve the comfort of use degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

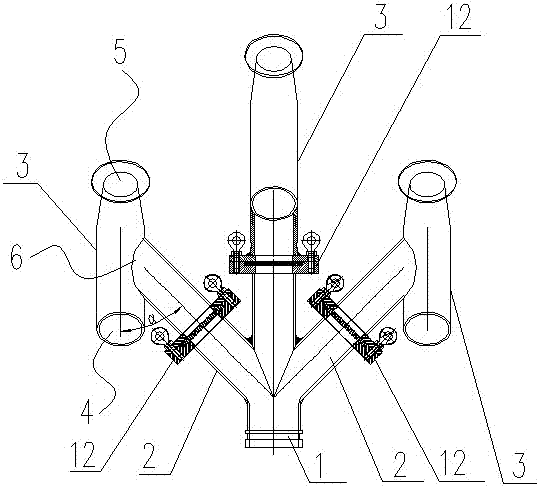

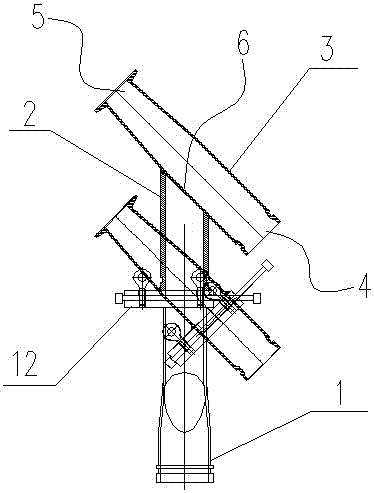

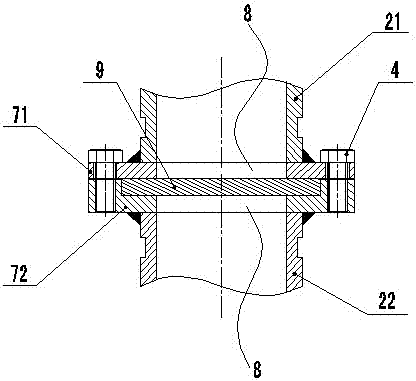

[0022] Such as Figure 1 to Figure 5 As shown, a multi-head discharge device of a wet spraying machine of the present invention includes a main pipe 1 communicated with a concrete delivery pipeline, and at least three branch pipes 2 connected thereto are fixed on the main pipe 1. Described branch pipe 2 is set as three. The discharge end of each branch pipe 2 is provided with an air material mixer 3, and the angle α between the central axis of the air material mixer 3 and the central axis of the corresponding branch pipe 2 is an acute angle, preferably 45°. The air material mixer 3 includes an air inlet 4 and a material outlet 5 which are arranged at both ends of the air material mixer 3 in the axial direction, and the air material mixer 3 is located at a position between the air inlet 4 and the material outlet 5 A feed inlet 6 is provided, and the air feed mixer 3 is connected to the discharge end of the corresponding branch pipe 2 at the feed inlet 6 .

[0023] Since the a...

Embodiment 2

[0028] The difference between this embodiment and embodiment one is that the arrangement forms of the three branch pipes 2 and the air material mixer 3 are different, such as Image 6 As shown, the branch pipe 2 is provided with three, wherein the air material mixers 3 arranged on the two branch pipes 2 are parallel to each other, and the outlets 5 of the air material mixers all point to obliquely downward; The discharge port 5 of the air material mixer 3 points obliquely upwards.

[0029] The arrangement of the three branch pipes 2 and the air material mixer 3 is not limited to the above embodiment, and the arrangement of the air material mixer can also be arranged in other schemes.

[0030] The present invention arranges at least three branch pipes 2 and air material mixer 3, and each branch pipe 2 is equipped with a flow regulating structure, which can freely and flexibly switch the discharge port and control the amount of concrete spraying according to the demand of workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com