A photoelectric direct reading spectrometer

A photoelectric direct reading and spectrometer technology, applied in the field of spectral decomposition, can solve the problems of heat energy waste, fuel waste, inability to switch temperature, etc., and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

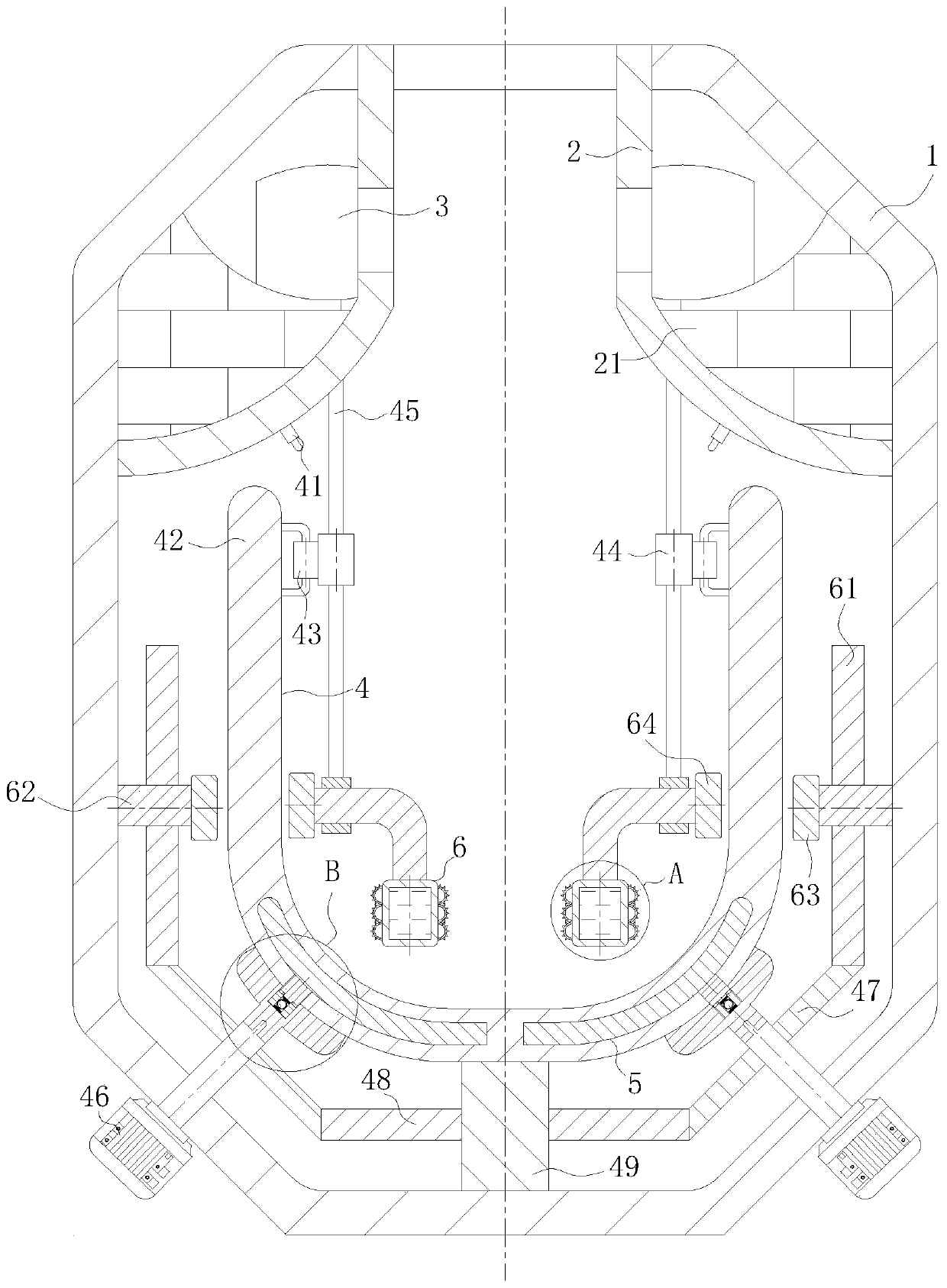

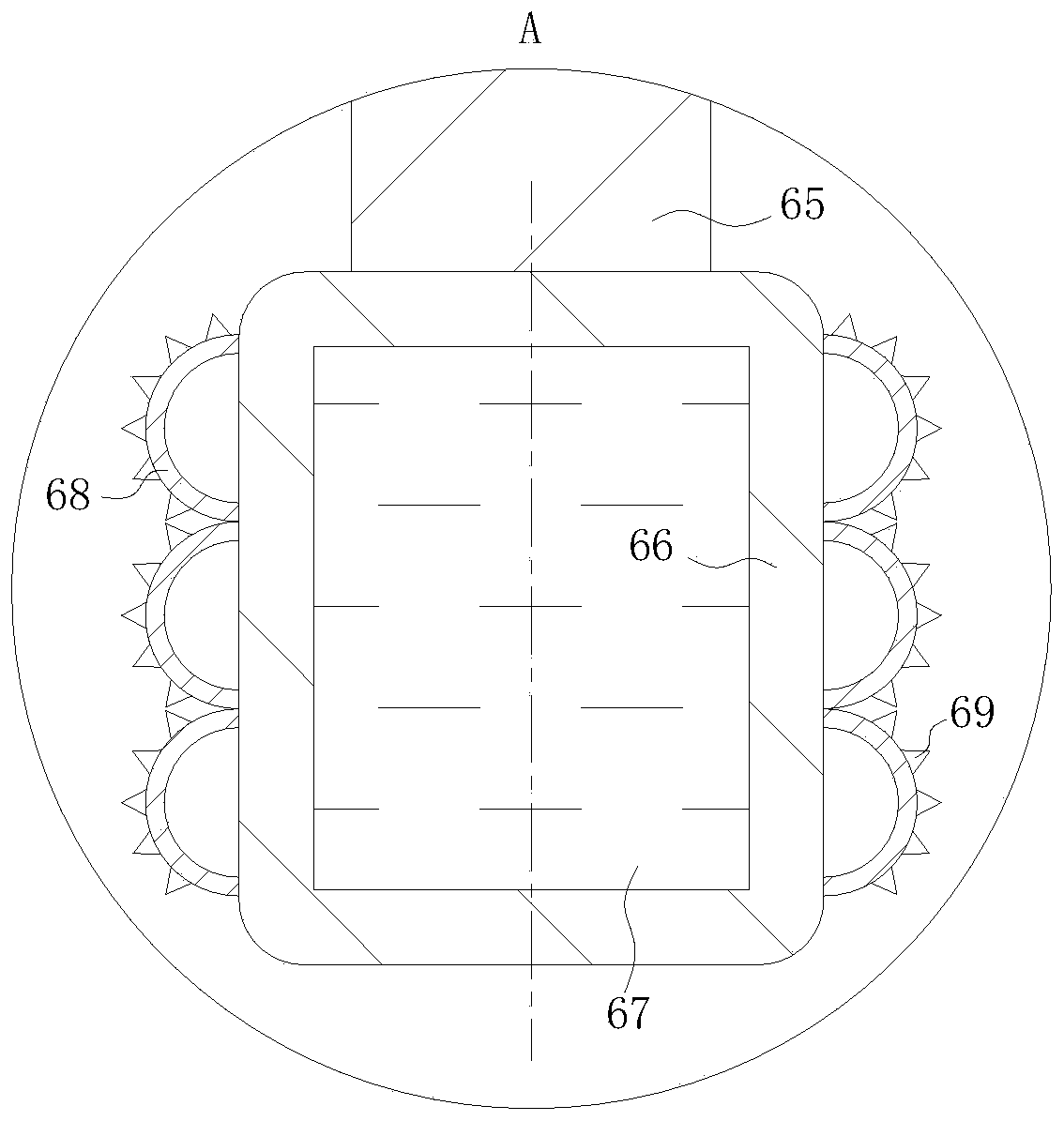

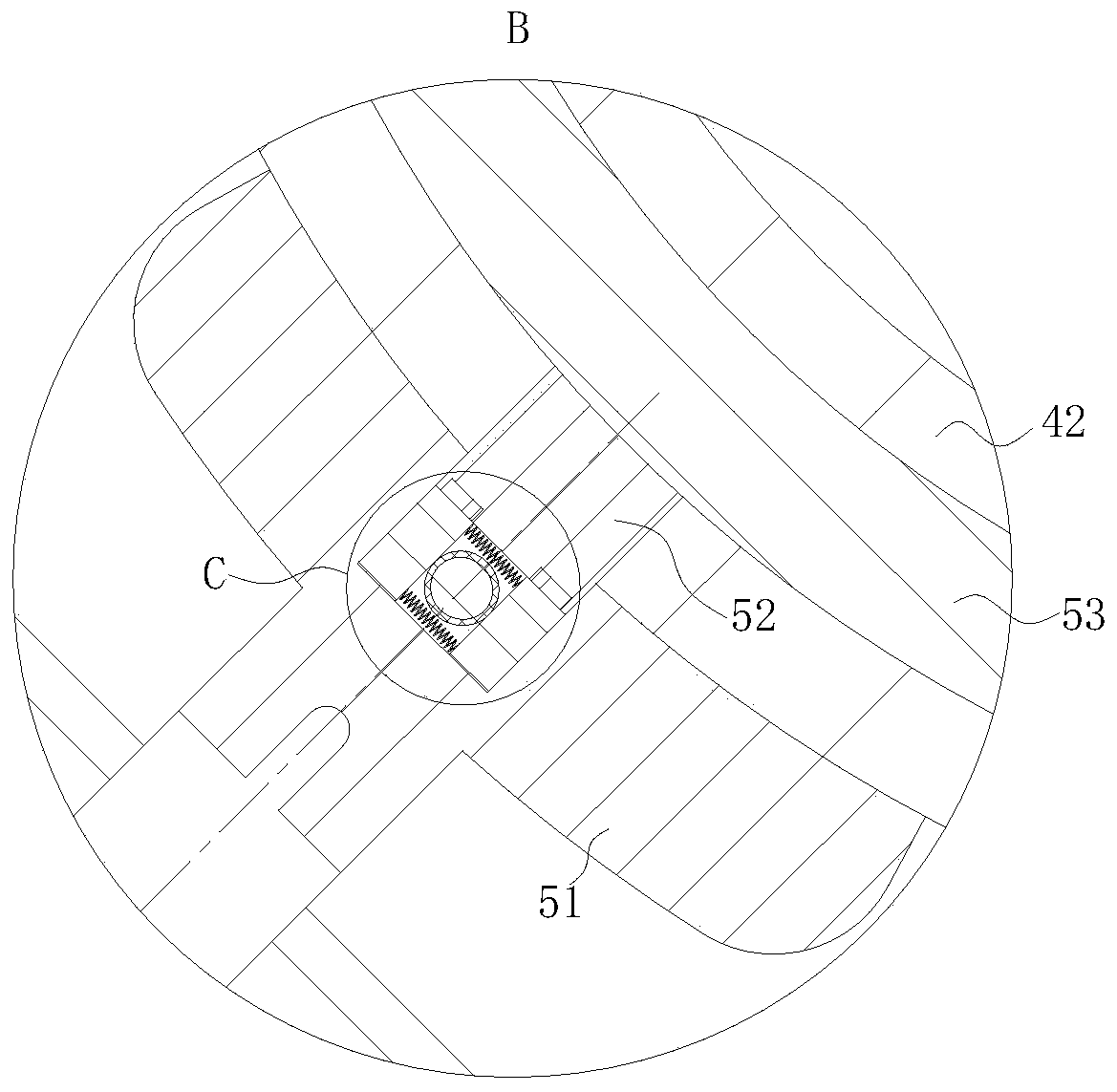

[0019] use Figure 1-Figure 4 A photoelectric direct reading spectrometer according to an embodiment of the present invention is described as follows.

[0020] like Figure 1-Figure 4As shown, a photoelectric direct reading spectrometer according to the present invention includes a main frame body 1, a partition plate 2, a spectrometer body 3, a rotating heating mechanism 4, a heat preservation mechanism 5 and a stirring mechanism 6; the inside of the main frame body 1 Both sides of the upper end are fixedly connected with a partition 2; the partition 2 is arc-shaped, and the inner lower end of the partition 2 is filled with an asbestos layer 21, and a rotating heating mechanism 4 is arranged below the partition 2; the upper end of the asbestos layer 21 The spectrometer body 3 is fixedly installed; the rotating heating mechanism 4 includes a gas injection port 41, a rotary furnace 42, a No. 1 flint 43, a No. 2 flint 44, a connecting rod 45, a motor 46, a bevel gear 47, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com