Fume welding and dust removing system for robot welding work station

A robot welding and dust removal system technology, applied in the direction of smoke removal, welding equipment, auxiliary welding equipment, etc., can solve problems such as human hazards, and achieve the effect of low hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

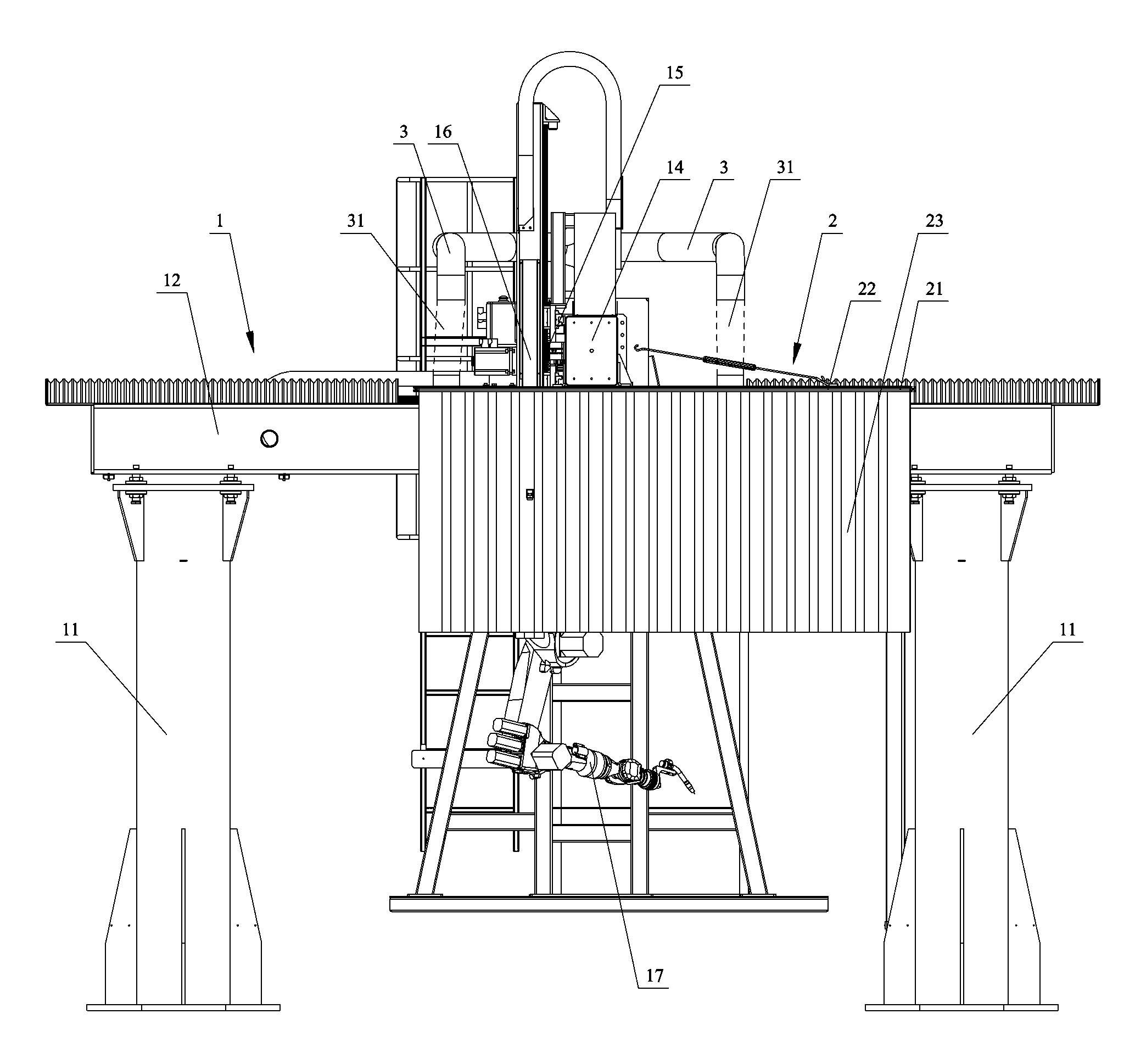

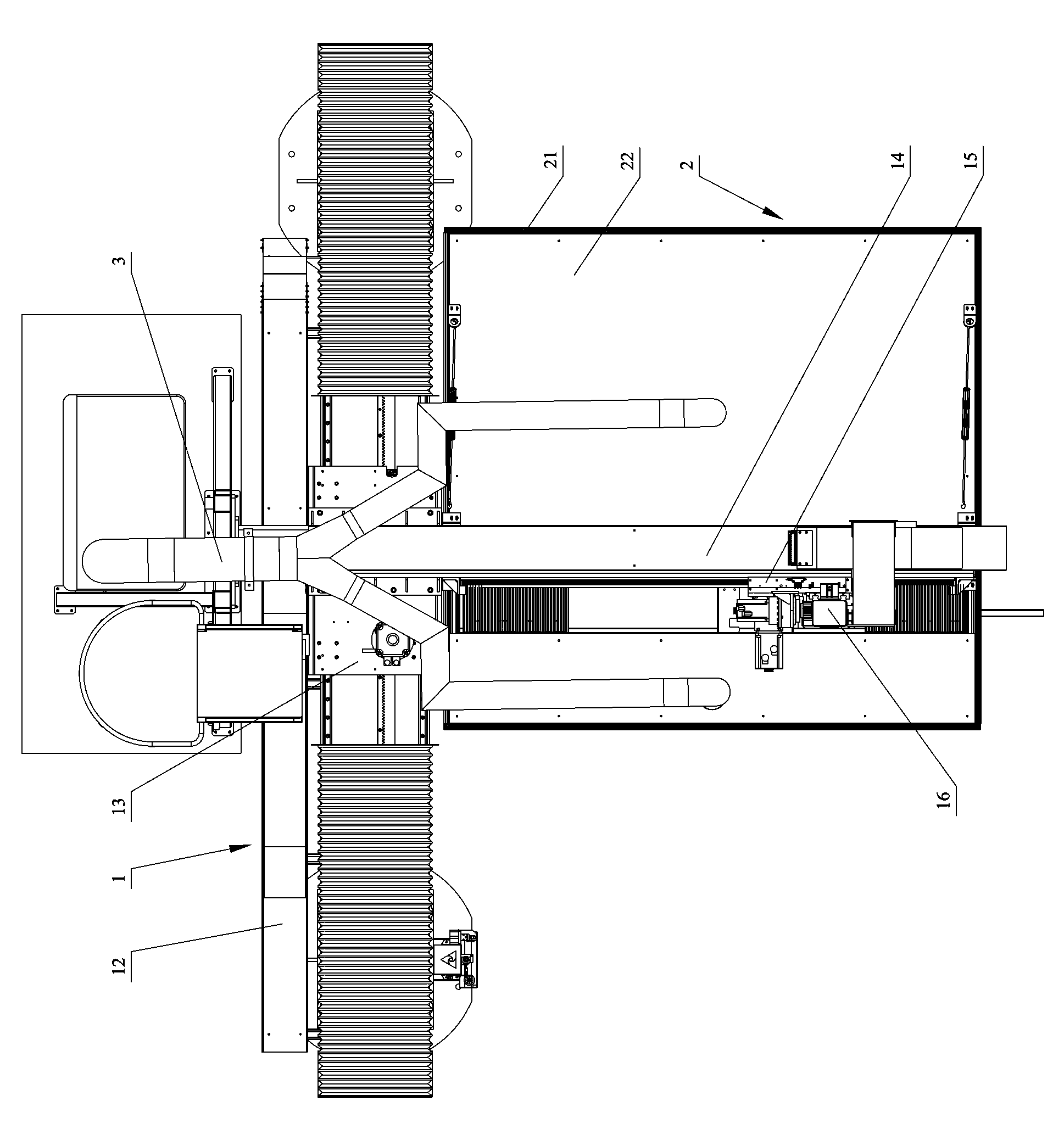

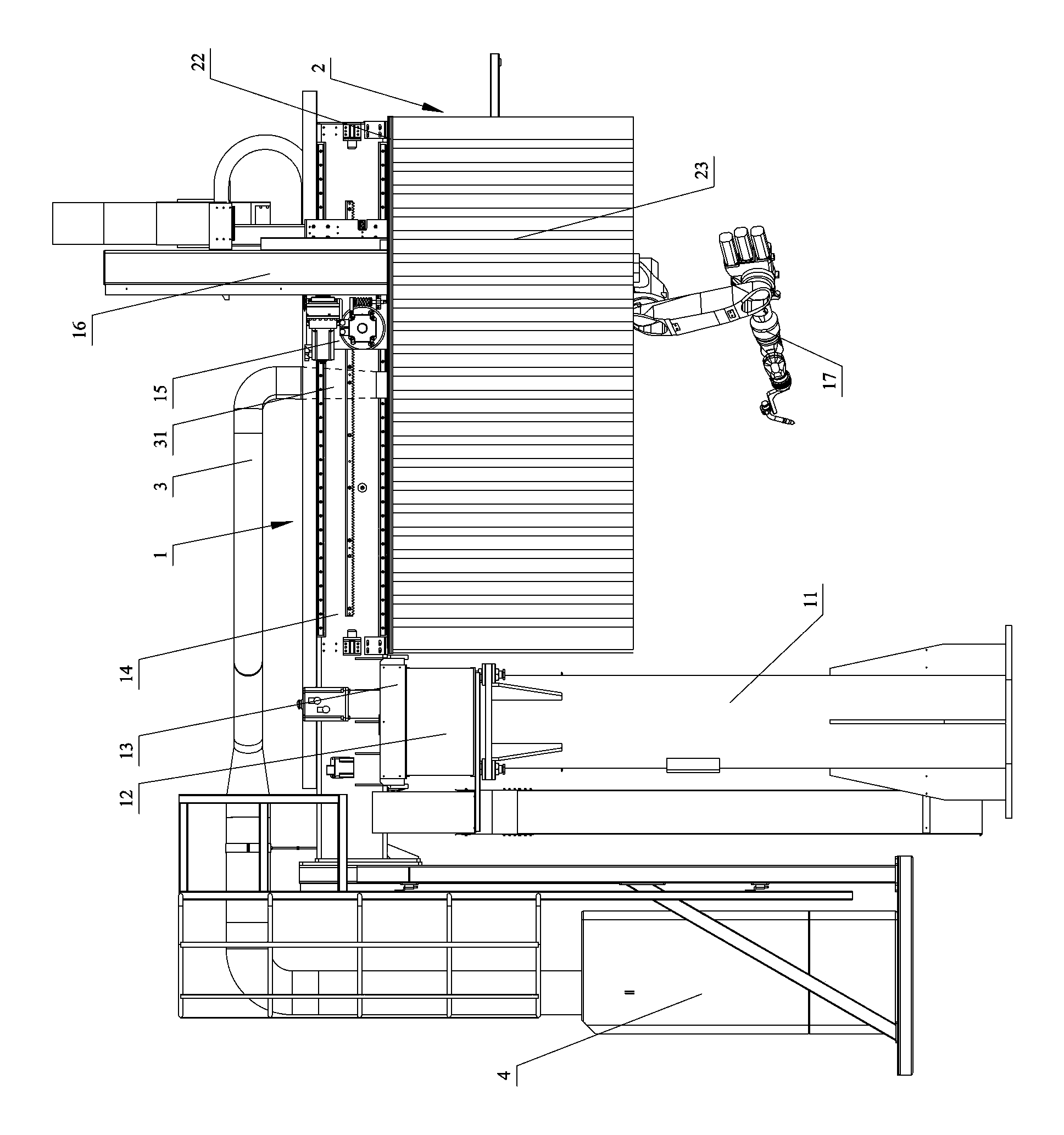

[0024] Embodiment one: see attached figure 1 to attach image 3 shown.

[0025] A welding fume and dust removal system for a robot welding workstation, which is installed in the robot welding workstation to absorb and filter the fume generated at the welding arc point 17 during welding.

[0026] The robotic welding workstation includes a three-axis gantry 1 . The three-axis gantry 1 includes a column 11 , an X-axis beam 12 , an X-axis slide 13 , a Y-axis beam 14 , a Y-axis slide 15 , and a Z-axis beam 16 arranged horizontally on the column 11 . The X-axis slide plate 13 is set on the X-axis beam 12 and slides along the X-axis beam 12, the Y-axis slide plate 14 is set on the X-axis slide plate 13 and is perpendicular to the X-axis beam 12 in the horizontal plane, and the Y-axis slide plate 15 is set on On the Y-axis beam 14 and slide along the Y-axis beam 14, the Z-axis beam 16 is arranged on the Y-axis slide plate 15 along the vertical direction and slides along the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com