Riveter for self-plugging rivets

A technology of blind rivets and riveting guns is applied in the field of automated machinery and equipment, which can solve problems such as affecting work efficiency, high linkage control requirements, and unfavorable work, and achieve the effects of reducing equipment costs, expanding the scope of application, and facilitating control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

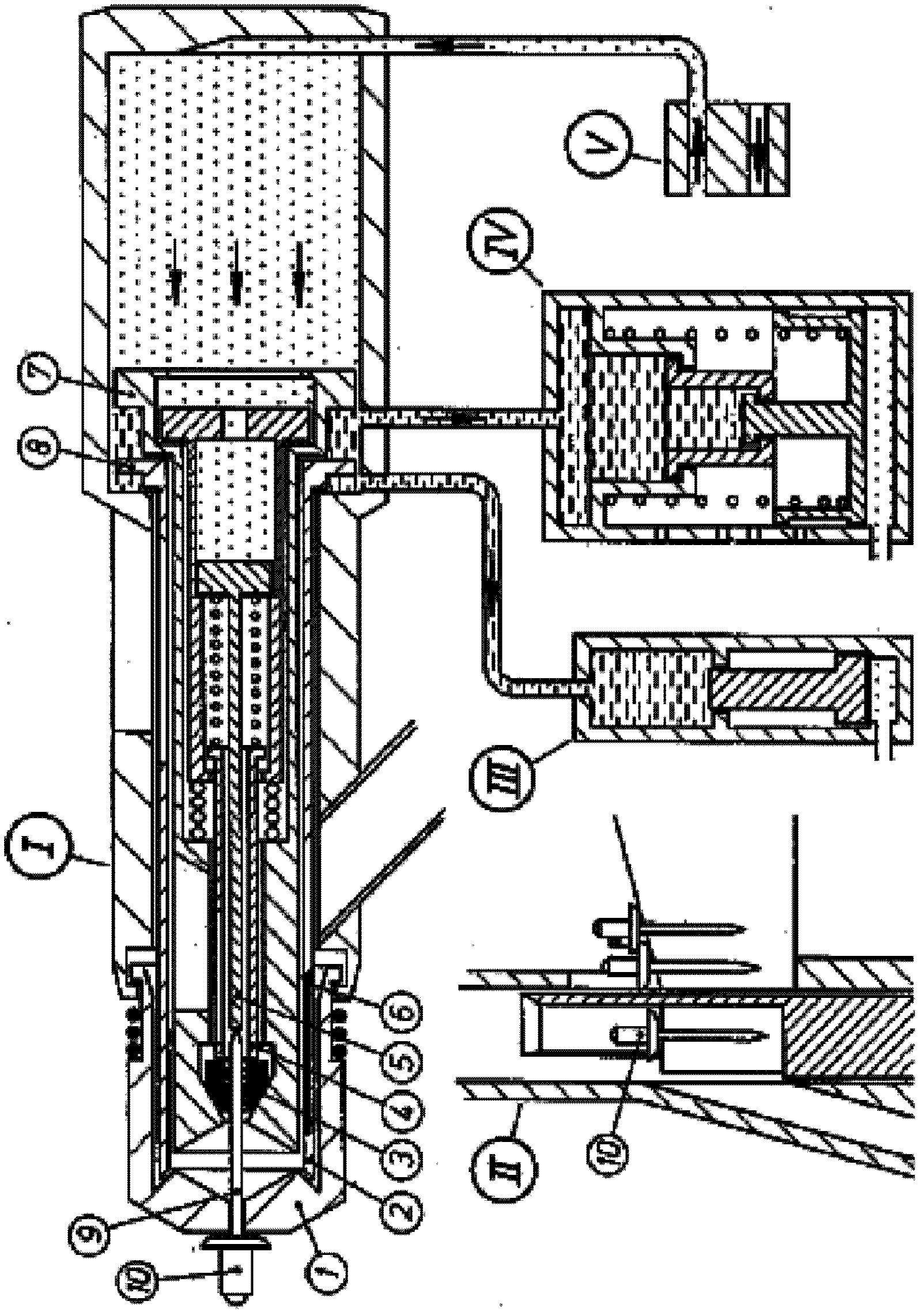

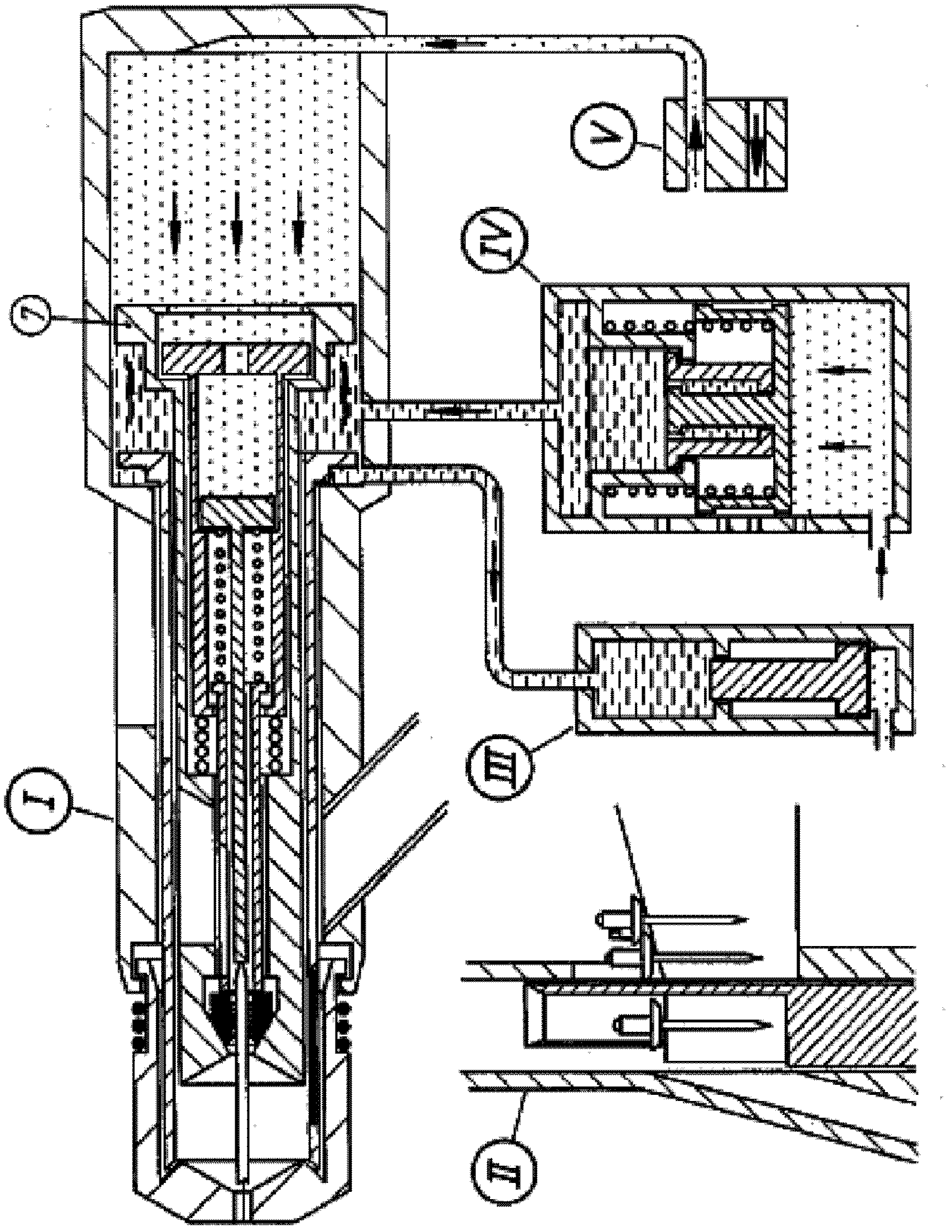

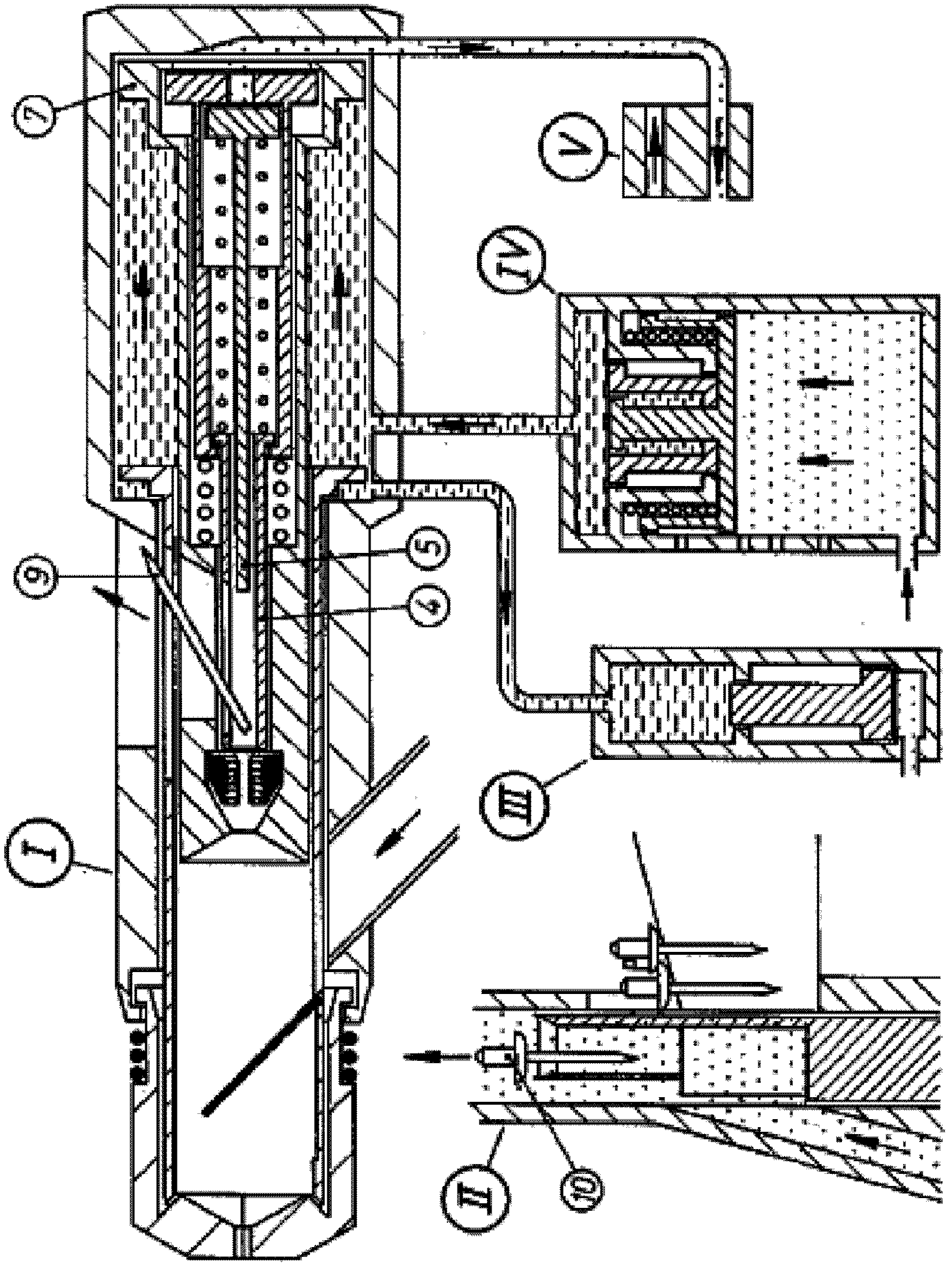

[0038] The blind rivet involved in the blind rivet gun for blind rivets of the present invention includes a rivet body 10 and a mandrel 9, such as Figure 5 with 6 As shown in the figure, the rivet is integrated when the riveting is not completed. After the riveting is completed, the mandrel needs to be disconnected from the riveting body to ensure that the riveted part is flat and beautiful.

[0039] A riveting gun for blind rivets according to the best embodiment of the present invention, such as figure 1 As shown, it includes a gun body I, a power mechanism that provides power to the gun body, a nail feeding mechanism II that conveys rivets to the gun body by air pressure, and a control mechanism that regulates the action coordination between the mechanisms (not shown in this application) It can be any technical means that can achieve this function in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com