Grinding machine

A grinding machine and grinding wheel technology, which is applied in the field of grinding machines, can solve the problems of high labor intensity, physical exertion, and inconvenient use, and achieve the effects of high safety performance, good grinding efficiency, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

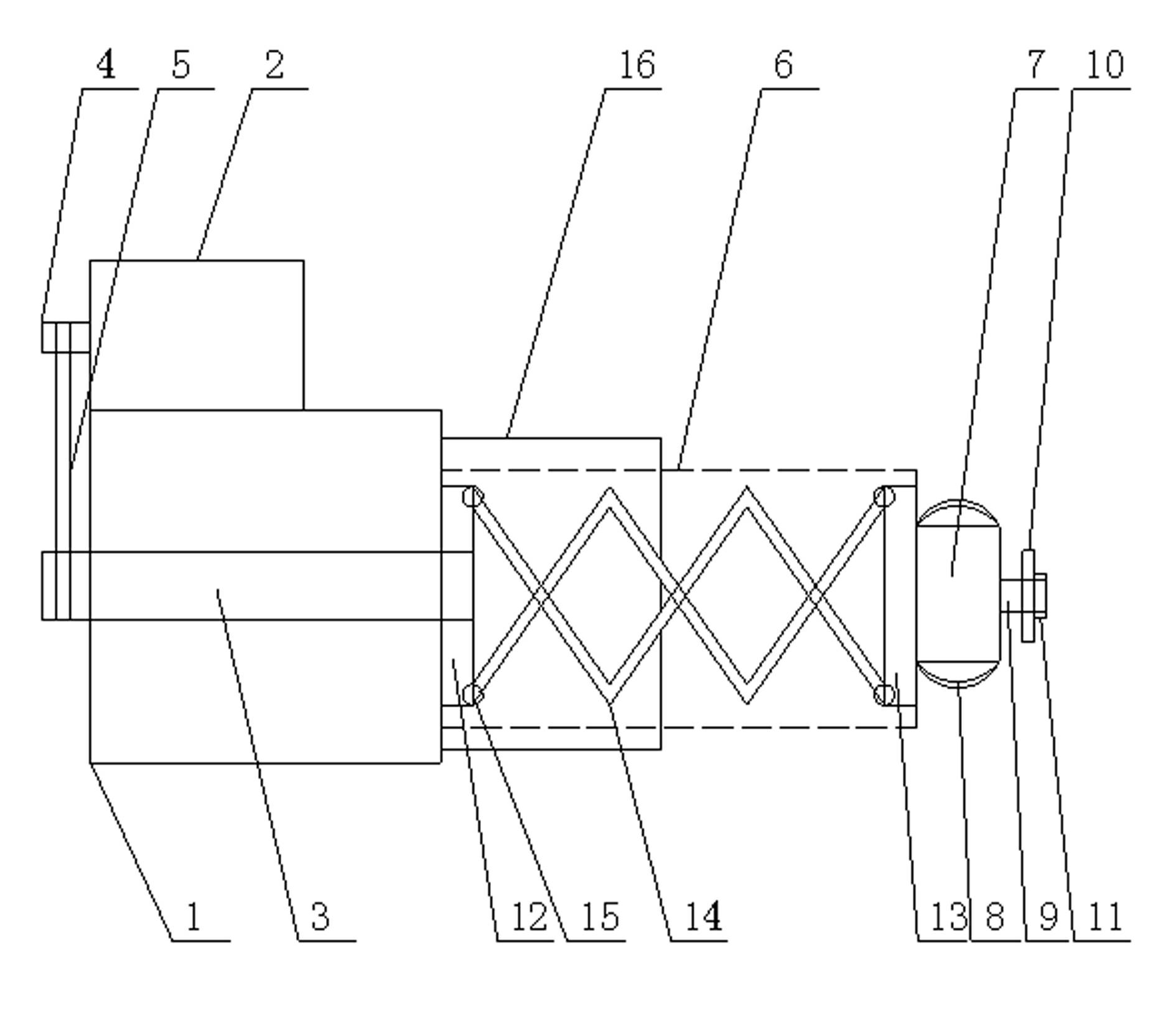

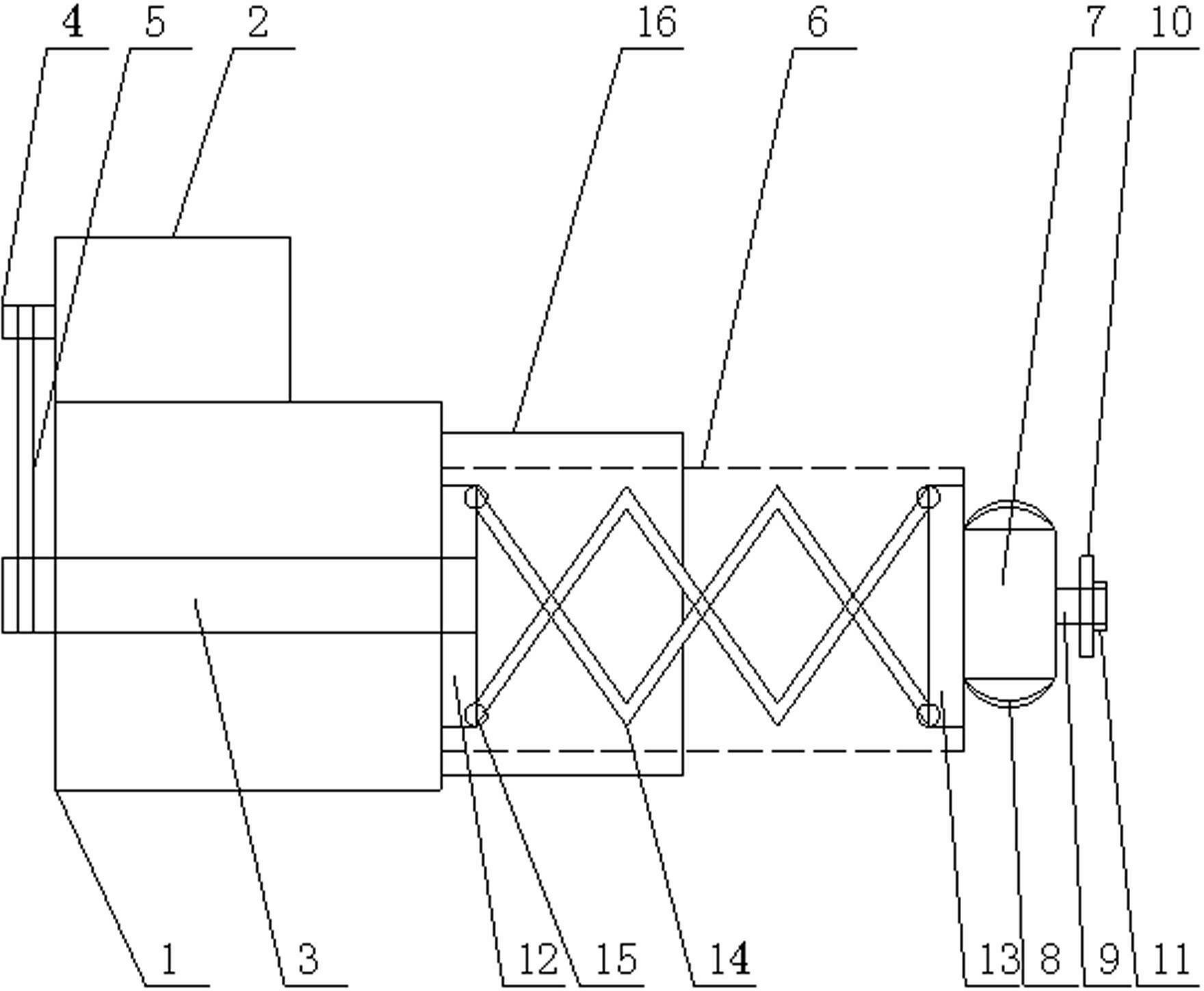

[0012] Such as figure 1 As shown, a kind of grinder of the present invention comprises a support 1 and a motor 2, the support 1 is provided with a main shaft 3, the motor 2 is provided with a motor shaft 4, and the main shaft 3 and the motor shaft 4 pass through The belt 5 is connected, the main shaft 3 runs through the machine base 1 and is connected to one side of the telescopic device 6 located on the outside of the machine base 1, and the other side of the telescopic device 6 is connected to the handle seat 7, and both sides of the handle seat 7 are A handle 8 is provided, and the handle seat 7 is connected to the grinding wheel shaft 9 away from the side of the telescopic device 6. The grinding wheel shaft 9 is provided with a grinding wheel 10, and the grinding wheel 10 is fixed by a fixed bearing 11. The telescopic device 6 includes a telescopic table a12 , telescopic table b13 and telescopic rod 14, described telescopic rod 14 is connected with telescopic table a12...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap