Three-degree-of-freedom parallel-connection mechanical wrist

A degree of freedom and parallel technology, applied in the field of mechanical wrists, can solve the problems of heavy weight and large moment of inertia of mechanical wrists, and achieve the effect of simple and compact structure, high degree of modularization, and error compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

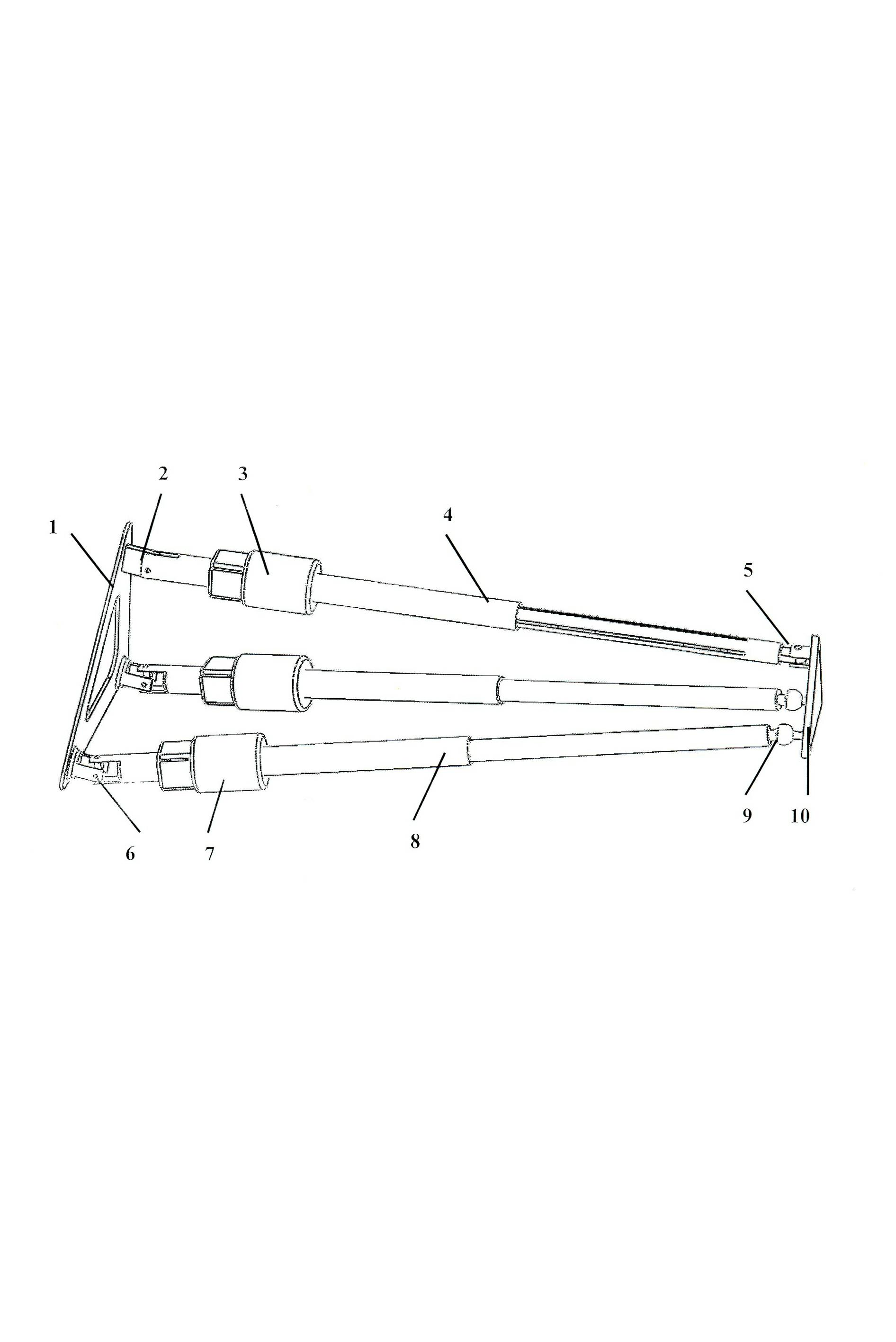

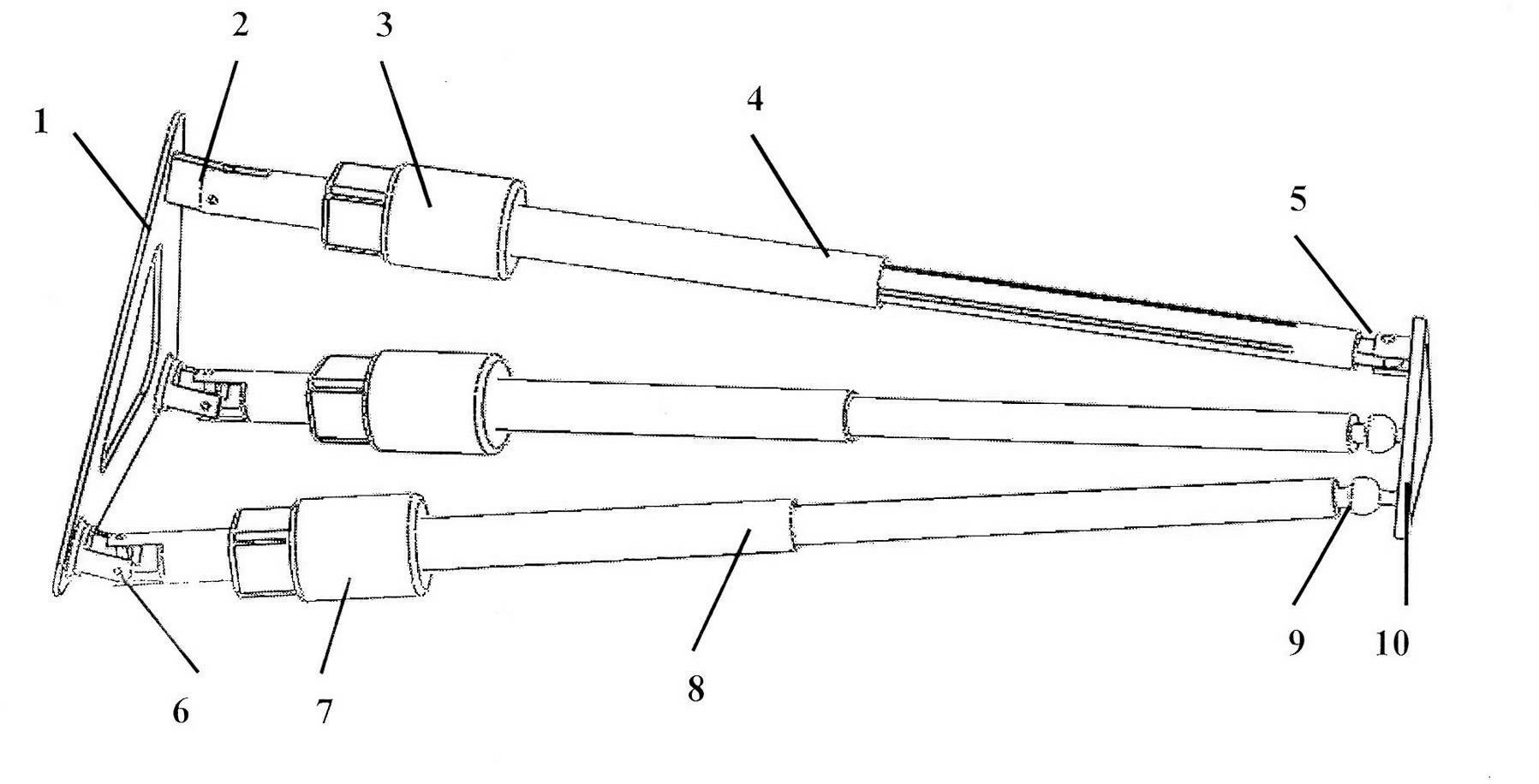

[0017] exist figure 1 In the three-dimensional schematic diagram of a 3-DOF parallel mechanical wrist shown, the two ends of a constrained driving branch chain and two driving branch chains with the same structure are respectively connected to the machine base 1 and the moving platform 10, and the connection points are all in the shape of an equilateral triangle Symmetrically distributed, the driving motors 3 and 7 of each branch chain are all installed on the mobile pair near the side of the machine base. The constraining driving branch chain is an RPR type series structure, in which one end of the driving moving pair 4 is connected to the machine base through the rotating pair 2 , and the other end of the driving moving pair is connected to the moving platform through the rotating pair 5 . The axes of the above two revolving pairs are respectively parallel to the planes of the machine base and the moving platform. When the rotation angles of the above two revolving pairs are...

Embodiment 2

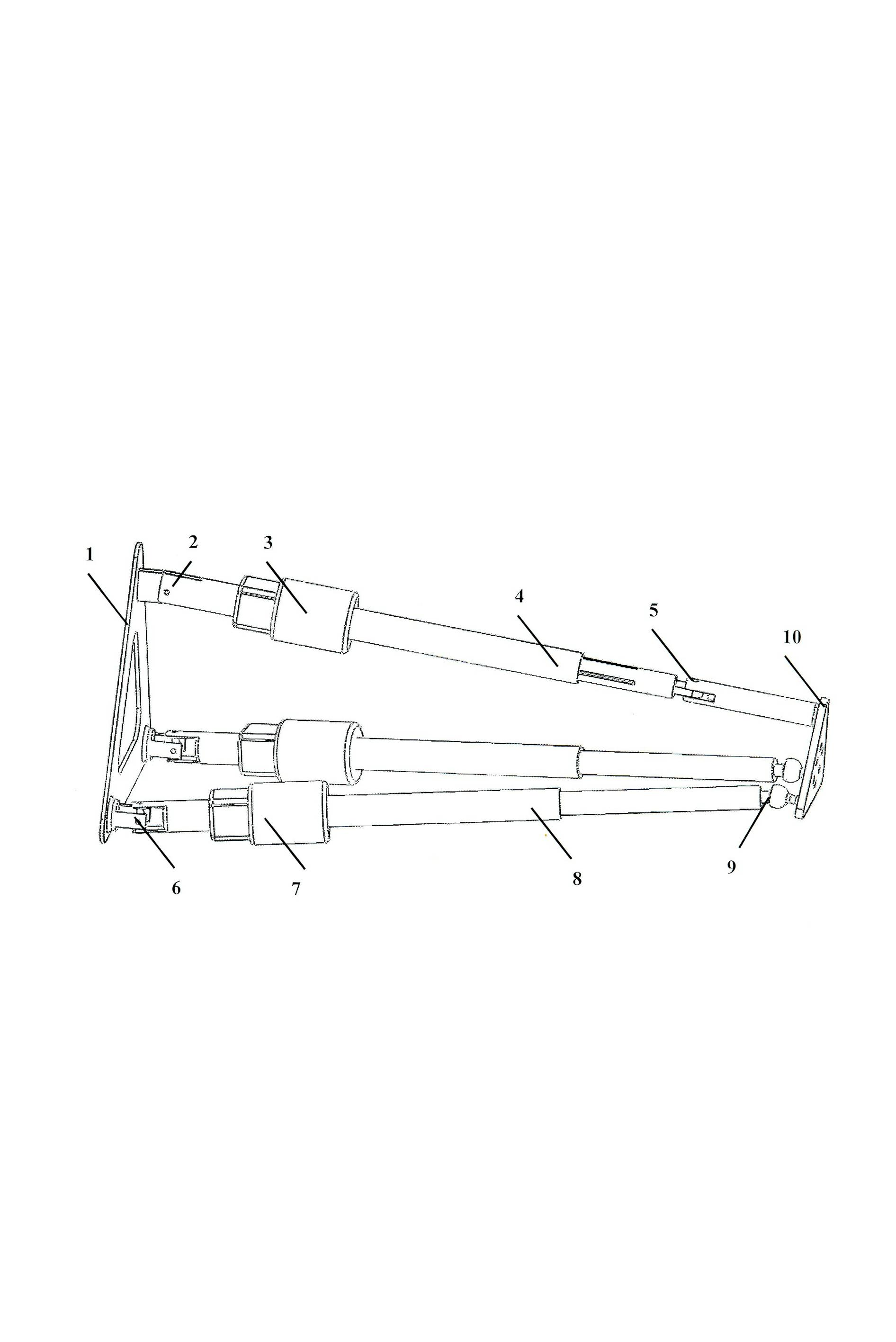

[0019] exist figure 2 In the three-dimensional schematic diagram of a parallel mechanical wrist with 3 degrees of freedom shown, the length between the center line of rotation of the revolving pair 5 and the moving platform 10 in the constraining drive branch chain is increased, and other components and their connection relationship are the same as figure 1 same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com